Also note the calculation for equivalent values:

× × + + × ×

=

× + + ×

3 3

2m,1* 1* 2k,acc,1* 2m,n* n* 2k,acc,n*

3

2k,eq*

2m,1* 1* 2m,n* n*

n t M ... n t M

M

n t ... n t

× × + + × ×

=

× + + ×

3 3

2m,1* 1* 2rad,acc,1* 2m,n* n* 2rad,acc,n*

3

2rad,eq*

2m,1* 1* 2m,n* n*

n t F ... n t F

F

n t ... n t

The following apply to the bearing service life L

10h

(ED

10

≤ 40%):

L

10h

> 10000 h with 1 < M

2kN

/M

2k*

< 1.25

L

10h

> 20000 h with 1.25 < M

2kN

/M

2k*

< 1.5

L

10h

> 30000 h with 1.5 < M

2kN

/M

2k*

For different duty cycles:

10

10h 10h(ED 40%)

10

40%

L L

ED

=

> ×

4.6.3 Recommendation for radial shaft seal rings

For a duty cycle > 60% and higher surrounding temperatures, we recommend radial shaft seal rings made of

FKM at the output.

Properties:

• Excellent temperature resistance

• High chemical stability

• Very good resistance to aging

• Excellent resistance in oils and greases

• For use in the food, beverage and pharmaceutical industries

Leak-proofness

Our gear units are equipped with high-quality radial shaft seal rings and checked for leaks. However, a leak

cannot be fully ruled out over the length of use of a gear unit. If you use a gear unit with goods incompatible

with the lubricant, you must take measures to prevent direct contact with the gear unit lubricant in case of a

leak.

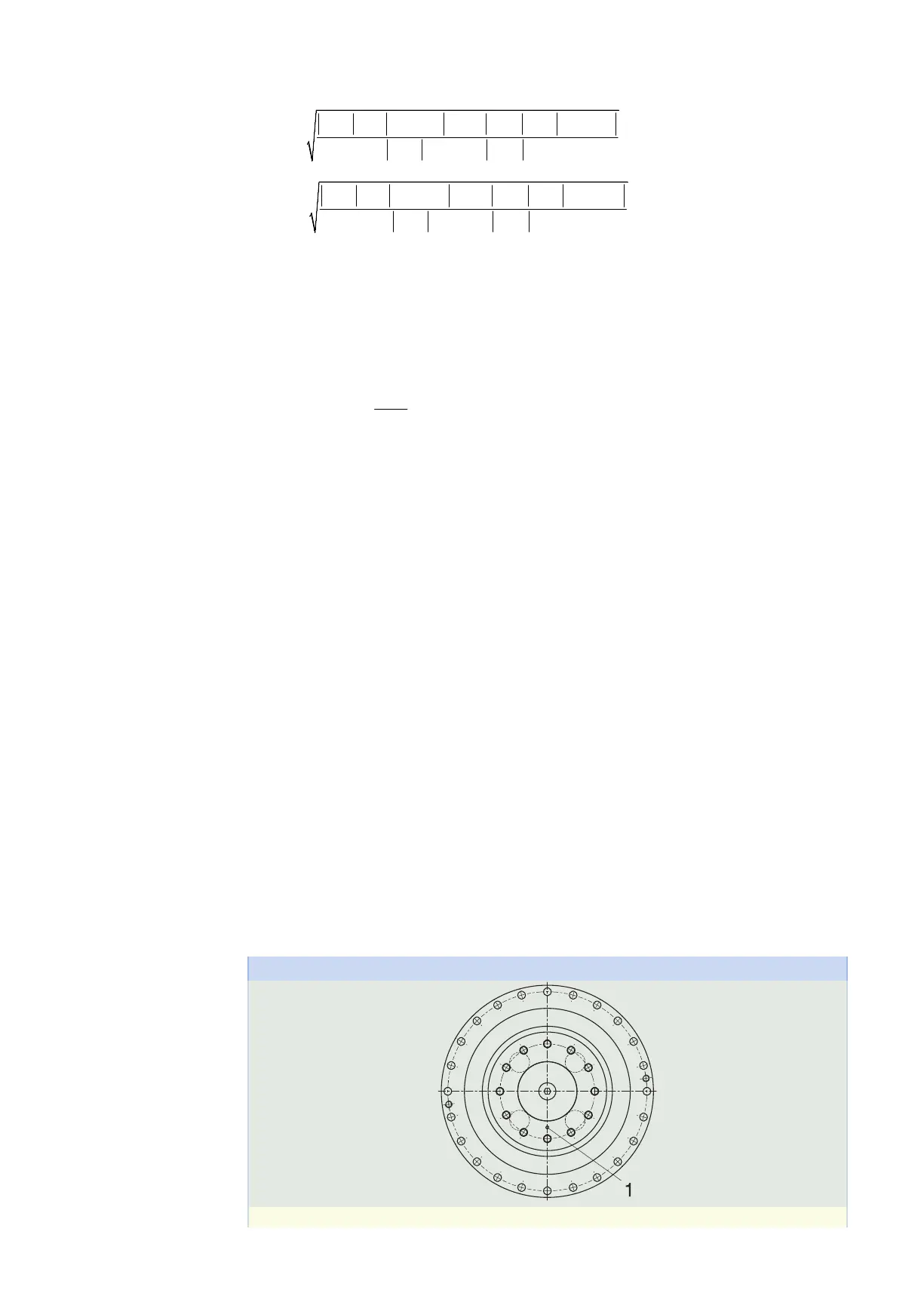

4.6.4 Reverse operation

To ensure lubrication for circulating gearing parts during cyclic reverse operation from ±20°to ±90° at the

output, pay careful attention to the position of the output shaft for the horizontal mounting of the gear

unit, as shown in the diagrams below.

The images show the center position of reverse operation.

Cyclic reverse operation ≤±20° on request.

PHQ4 − PHQ12

1 Position of the mark: bottom

Please note that the hole pattern may be different, depending on the size of the planetary gear unit.

4.6 Project configuration 4 PHQplanetary geared motors

82

Loading...

Loading...