4.5.2.2 Brake

A failsafe brake is integrated into the motor adapter. It has the function of a holding brake. Braking from full

speed, e.g. in case of a voltage drop or an emergency off in hazard situations, is still possible.

The brake can be used as a single brake or together with the motor brake as a redundant brake system.

Function

The brakes installed in the motor adapter are electrically actuated spring-loaded brakes for dry running. In

the de-energized state, braking takes place using spring force. The brake is released by an electromagnetic

DC coil before the motor is switched on. The switch-on time t

2B

(release time) is the time until the anchor

plate releases from the axially moving brake disc and is magnetically held to the coil body. In this state, the

brake is released and the coupling hub can rotate. In order to switch off (motor and brake), the residual

magnetic flux of the iron parts (anchor and coil body) must be reduced; the associated time t

11B

until the

start of torque generation is defined as a response delay when linking. The link time t

1B

is the time until the

braking torque has built up to the nominal braking torque.

Manual release

Optionally, the brake can be equipped with a manual release.

Pressing the manual release deactivates the electronic actuation of the brake. Before pressing the manual

release, you must establish the safety of the machine (e.g. protection against falling).

4.5.2.3 Electrical connection

• Terminal box (standard)

• Plug connector (optional, not possible in combination with release monitoring)

4.5.2.4 Monitoring

For monitoring the brake system, there are generally two options:

• Manual monitoring of wear via air gap checks with a feeler gauge

• Electrical release monitoring in the terminal box with a non-contact and wear-free proximity switch

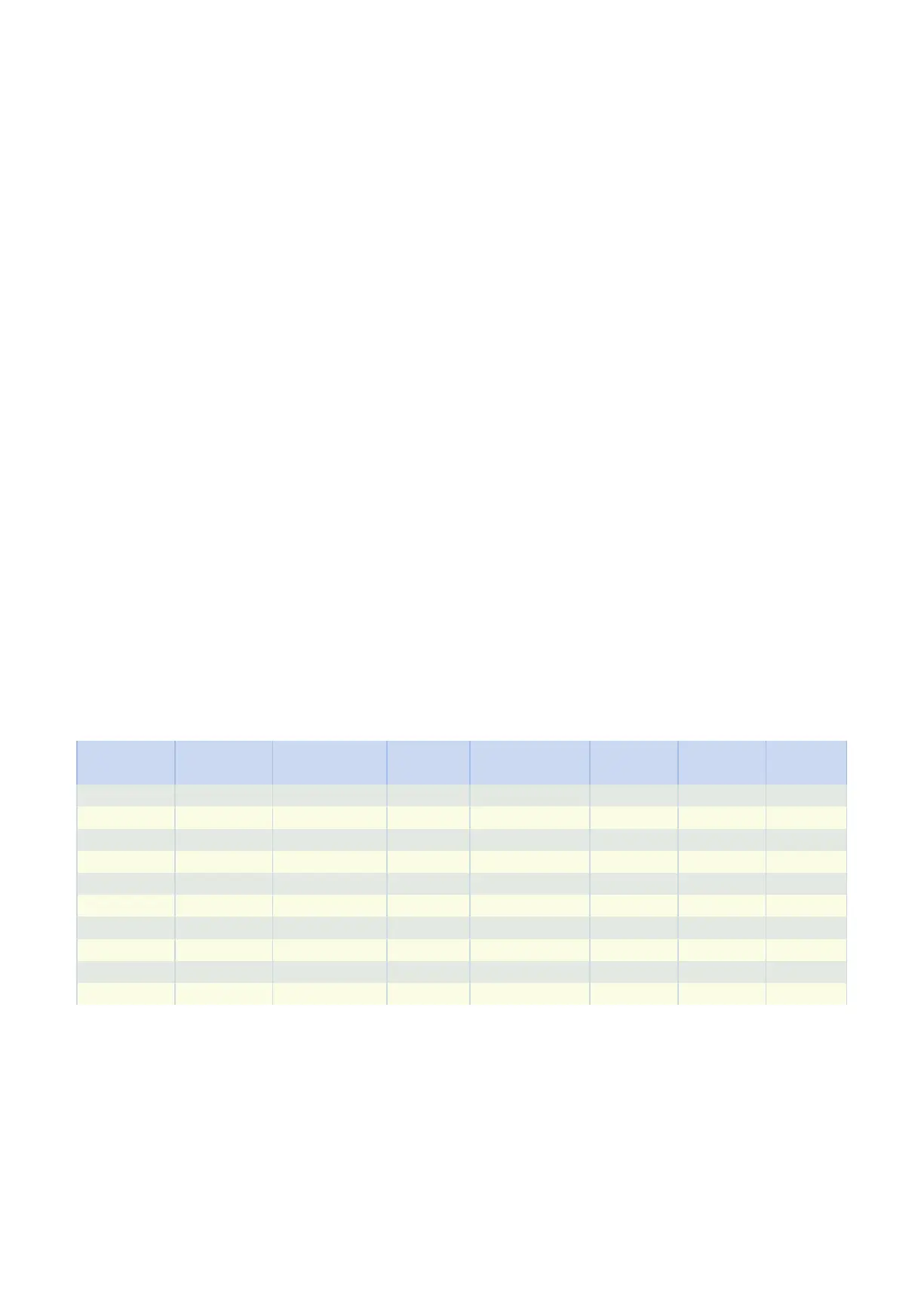

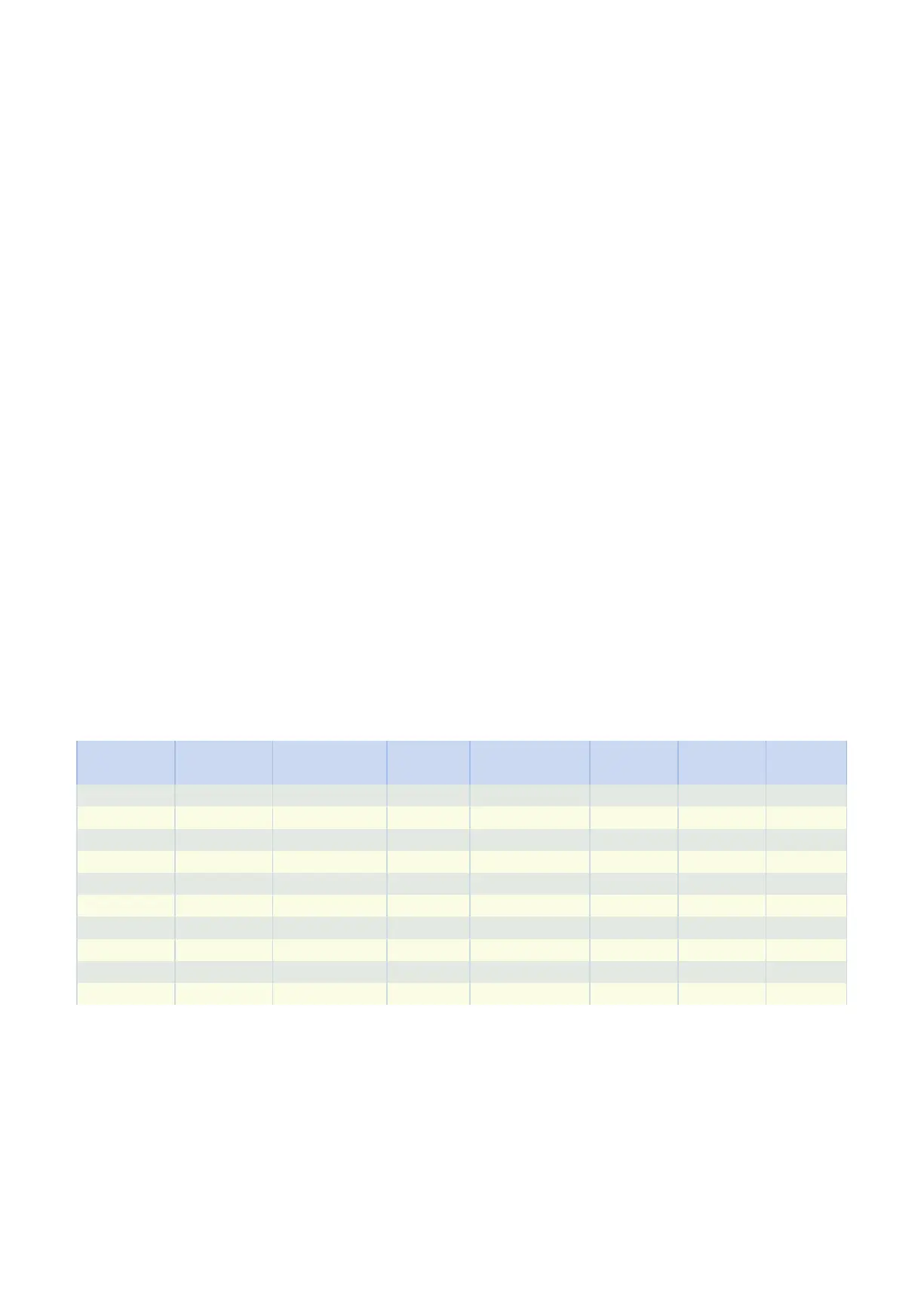

4.5.2.5 Brake technical data

Technical data for operation at 24VDC (±10%)

Type M

1Bstat

J

1

m Δφ

B

t

1B,DC

t

2B

P

N,B

[Nm] [kgcm²] [kg] [arcmin] [ms] [ms] [W]

MB23 8.0 6.3 8.5 32.0 65 55 30

MB23 12 6.3 8.5 32.0 55 80 30

MB33 16 26 14 26.0 150 60 37

MB33 24 26 14 26.0 120 85 37

MB33 32 26 14 26.0 95 100 37

MB33 45 26 14 26.0 80 120 37

MB43 50 69 26 19.0 150 100 55

MB43 72 69 26 19.0 120 150 55

MB43 100 69 26 19.0 90 200 55

MB53 200 236 61 17.0 200 250 86

Δφ

B

: With the brake closed, a higher total backlash results (Δφ

tot

= Δφ

2

+ Δφ

B

/ i).

4.5 Product description 4 PHQplanetary geared motors

72

Loading...

Loading...