208 Maintenance

V560 Series High Performance Closed-Loop Vector Inverter User Manual

9. MAINTENANCE

Many factors such as temperature, humidity, dust and vibration of the use environment, and internal

components aging, wear of frequency inverter, which may lead to hidden fault of frequency inverter. In order

to ensure the frequency inverter of long and steady operation, its maintenance is required in the storage and

the process of use.

After long-distance transportation of the frequency inverter, users should check whether the components are

in good condition, or the screws are fastened before use them. During the normal use period, users shall

regularly clean the internal dust of frequency inverter and check whether the screws are loose.

Due to the high voltage of frequency inverter in service, the wrong operation can result in serious injury or

death, therefore, the power supply of the frequency inverter shall be cut off, and the maintenance operation

after ten minutes after the nixie tube of the frequency inverter panel extinguishing can be carried out.

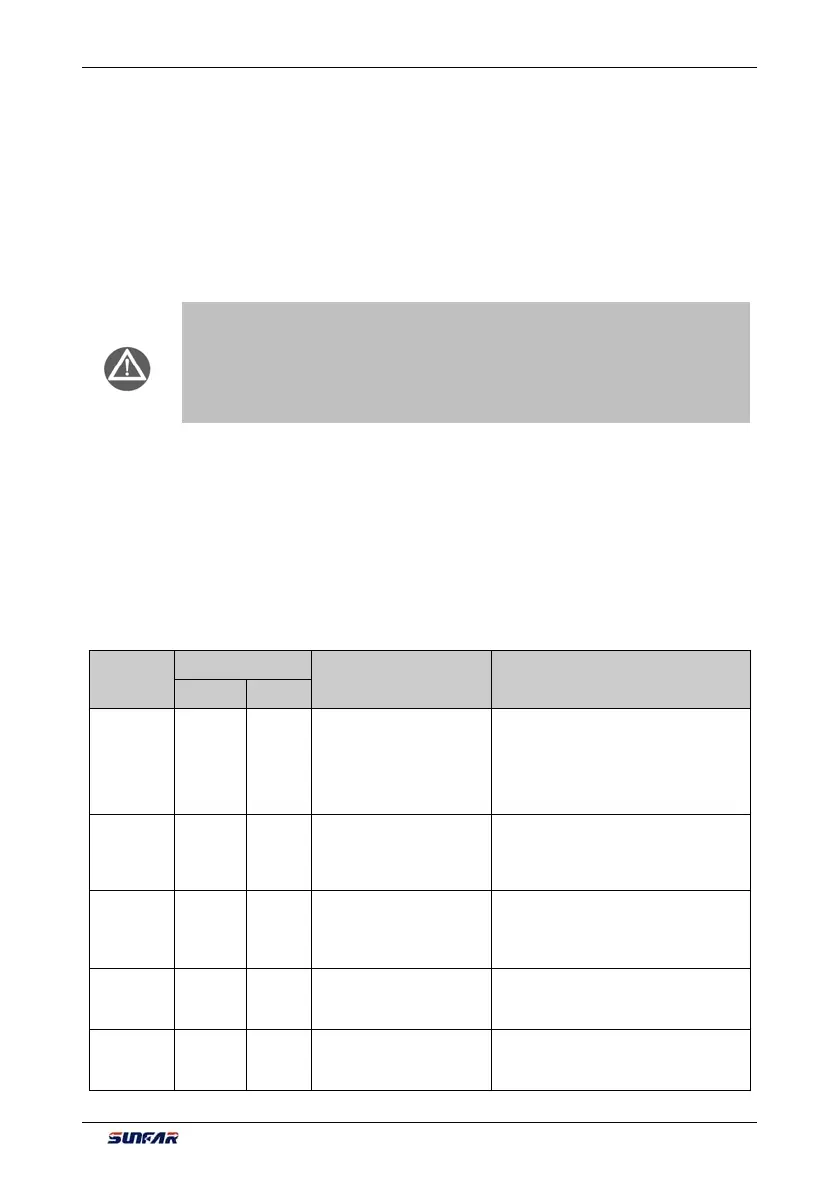

9.1 ROUTINE MAINTENANCE

Through routine maintenance, all kinds of abnormal condition and abnormal cause can be found promptly,

and the faults and hidden dangers can be eliminated as soon as possible. Thus, the normal operation of

equipment can be guaranteed and also the service life of the frequency inverter can be prolonged. Refer to

the following table for routine maintenance.

Table 9-1 Tips for inspection and maintenance

Object

checked

Inspection cycle

Scope of inspection Assessment criterion

Irregularly Regularly

Operation

environment

√

1. Humidity, temperature

2. Dust, moisture

3. Gas

1. Open the frequency inverter when the

temperature is above 45°C, keep

humidity below 95%, without frost

deposit

2. Free from peculiar odor, inflammable

and explosive gas

Cooling

system

√

1. Installation environment

2. Frequency inverter fan

1. The installation environment shall be

well ventilated and the duct has no block

2. Fan is in well operation and without

abnormal noise

Frequency

inverter

√

1.Vibration, temperature rise

2. Noise

3. Wire, terminal

1. Vibration is smooth and outlet

temperature is normal

2. No abnormal noise and no peculiar smell

3. No loose for fastening screw

Generator √

1. Vibration, temperature rise

2. Noise

1. Smooth operation and normal

temperature

2. No abnormalities and inconsistent noise

Input and

output

parameter

√

1. Input voltage

2. Output current

1. The input voltage is in the specified

scope

2. Output current is under the rated value

¾ The inspection shall be carried out by professional technician, and the power of frequency

inverter shall be cut off.

¾ For frequency inverter with more than half a year storage time, when an electric current is

applied, users shall boost the voltage slowly through voltage regulator to supply the

power, or otherwise will lead to the risk of electric shock and explosion (internal

electrolysis condenser).

Loading...

Loading...