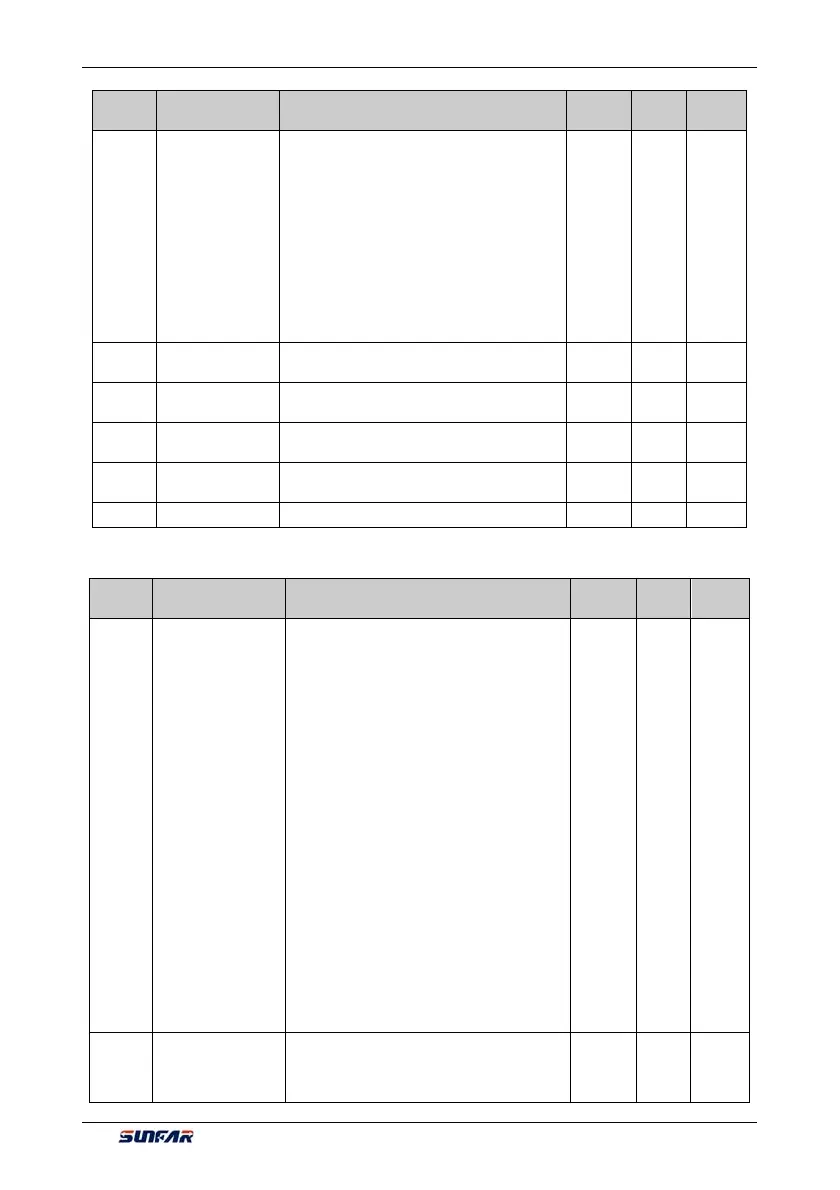

Functional Parameter Table

V560 Series High Performance Closed-Loop Vector Inverter User Manual

75

Function

Code

Name Setting Range and Description

Minimum

Unit

Factory

Default

Change

Limit

6: MODBUS Fieldbus set value 2

_ _ X _: Reserved

_ X _ _: Maximum torque selection source

0: Maximum torque set value 1 (F8.3.50)

1: Maximum torque set value 2 (F8.3.51)

2: Multifunctional selection terminal setting 1 or

2 (Function No. 36)

3: AI1 set value

4: AI2 set value

5: MODBUS Fieldbus set value 1

6: MODBUS Fieldbus set value 2

F8.3.48

Minimum torque

limit 1

-250.0~0.0% 0.1 -200.0

F8.3.49

Minimum torque

limit 2

-250.0~0.0% 0.1 -200.0

F8.3.50

Maximum torque

limit 1

0.0~250.0% 0.1 200.0

F8.3.51

Maximum torque

limit 2

0.0~250.0% 0.1 200.0

F8.3.52 Torque zero offset -25.0~25.0% 0.1 0.0

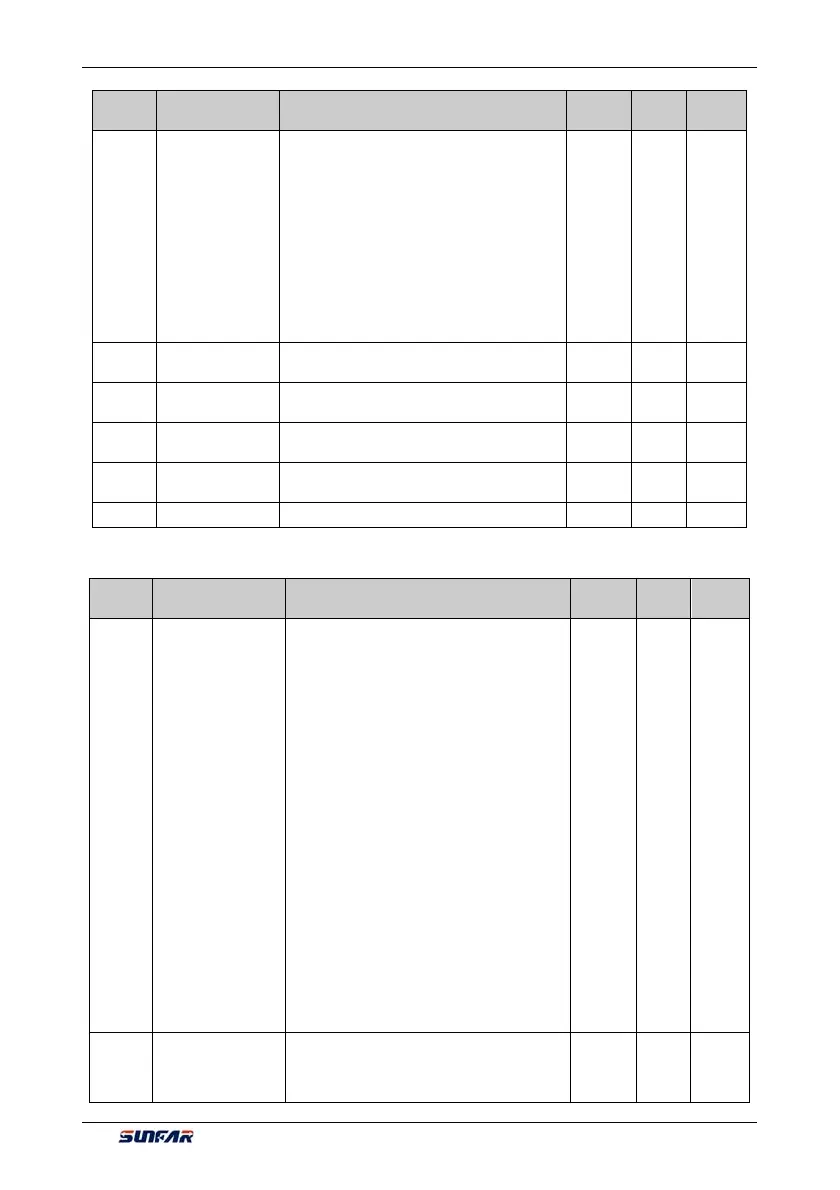

6.2.38 COMPENSATION PID (RUNNING CYCLE: 1MS)

Function

Code

Name Setting Range and Description

Minimum

Unit

Factory

Default

Change

Limit

F9.0.00

Compensation PID

function

_ _ _ X: Controller input

0: Closed

1: Synchronously effective with inverter running

command

2: Activated when the Multifunctional terminal is

effective (Function No. 25)

3: Immediately effective after the inverter is

powered on

_ _ X _: Reserved

_ X _ _: Controller output

0: Feed FWD compensation-added with the

frequency integrator output, and the

complementation ratio is set by parameter

F9.0.01

1: Independent PID- the output can be set by

the AO terminal output/torque.

2: Set PID–output used as frequency/

revolution command

X_ _ _: feed forward compensate frequency

benchmark

0: Relative to the upper frequency

1: Relative to the frequency integrator output

1 0100 ×

F9.0.01

Compensation

proportion (as

compared to upper

limiting frequency)

0.0~100.0(%) 0.1 50.0

Loading...

Loading...