214 Example of Usage

V560 Series High Performance Closed-Loop Vector Inverter User manual

second part)

16. F9.0.05= 0.2

Differential coefficient of PID in first part

17. F9.0.06= 5

Differential inertia filtering time PID in first part

18. F9.0.07= 1 Offset PID output of Inertia filtering time

19. F9.0.08= 0 Offset PID internal figure setup

20. F9.0.11= 62.5

Offset PID internal figure given= (R+r)*F/2T*100%

21. F9.0.12= 0 Offset PID feedback selects analog quantity Al1

22. F9.0.13= 0

Feedback input being 0V contrary to 0% feedback

23. F9.0.14= 8.3

Feedback input contrary to 100% feedback= Fm*(R+r)/ 2T*10, (Fm: full-scale

tension value of tension sensor; tension sensor output signal: 0-10V.

24. F9.0.15= (R + r)/2

Feedback multiplication factor transform feedback tension signal into torque

signal depending on feedback factor

25. F9.1.21= 0011

Offset PID selects double-PID parameter switch PID parameter according to

feedback value

26. F9.1.23= 0060

Feedback value of lower-limited switching value 60%

27. F9.1.24= 0080

Feedback value of top-limited switching value 80%

28. F9.1.29= 2

Proportional gain of PID in second part

29. F9.1.30= 18

Integral time of PID in second part

30. F9.1.31= 0.5

Differential coefficient of PID in second part

31. F9.1.33= 5 Regulator output of filtering time constant

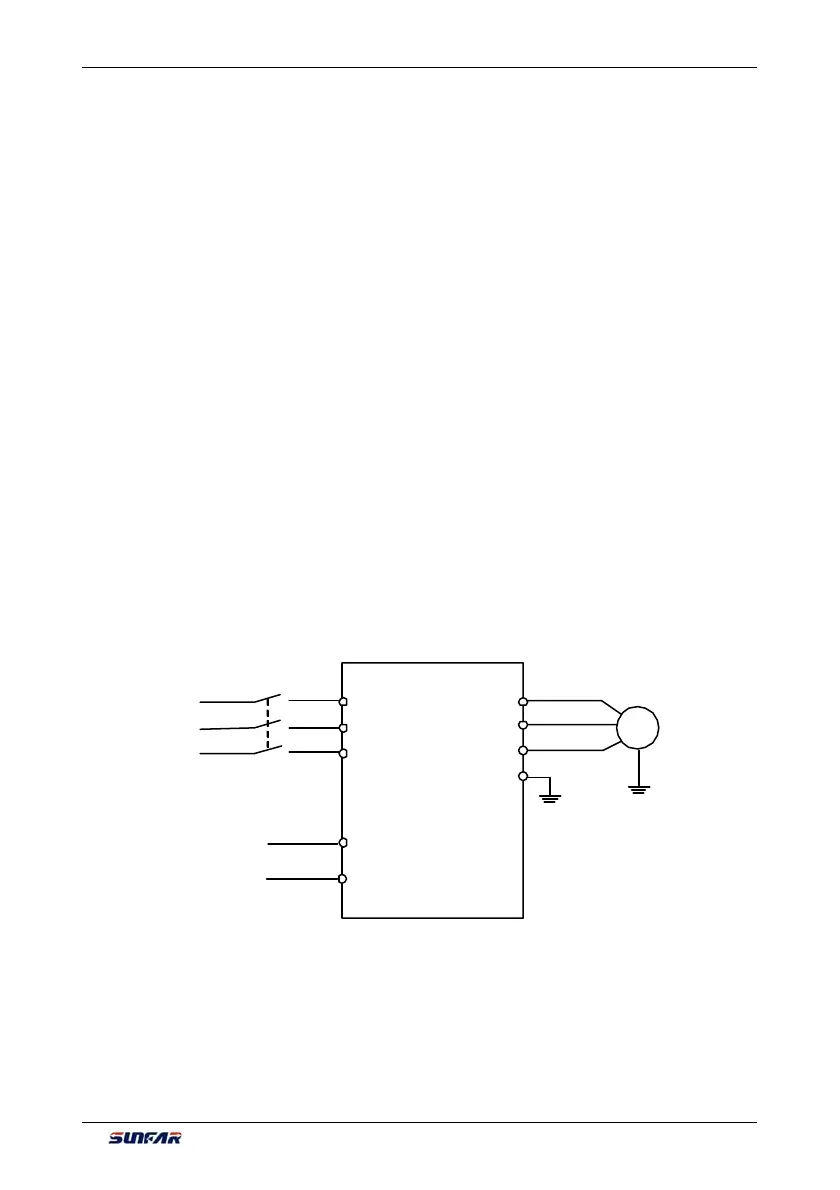

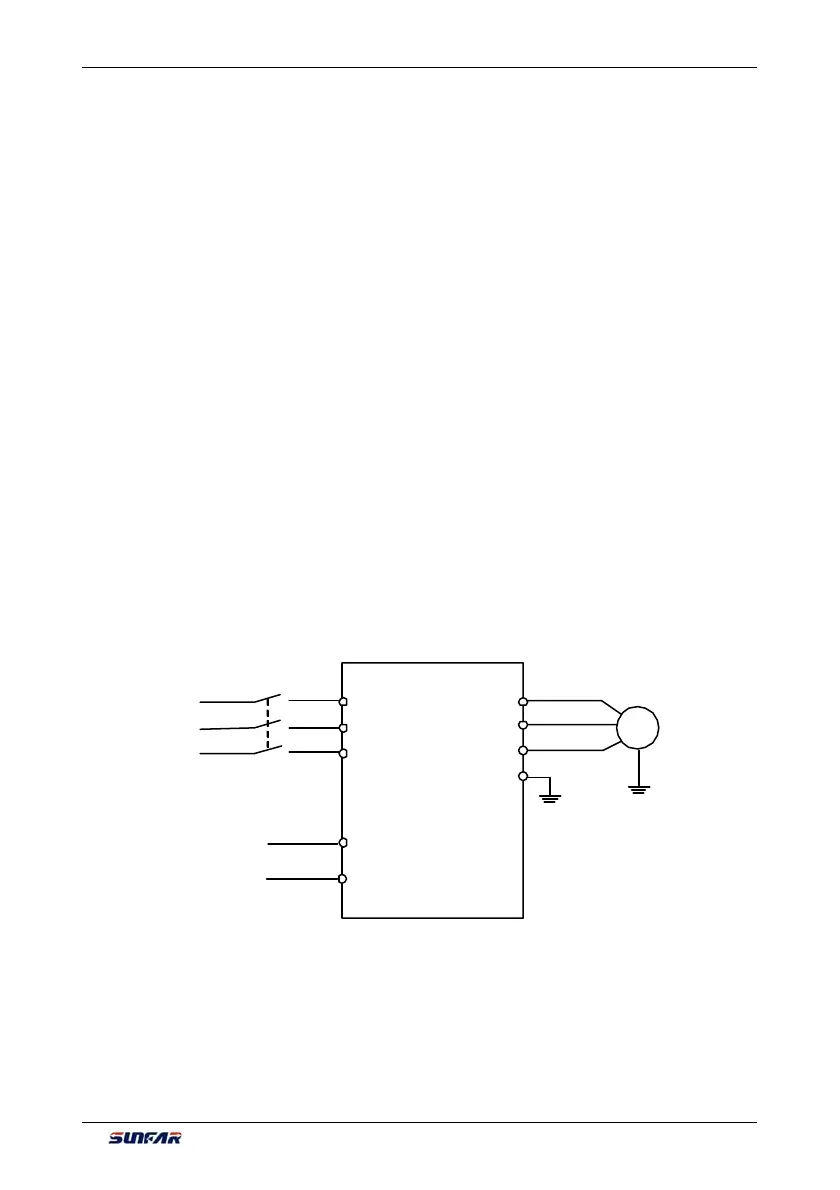

10.2.4 WIRING DIAGRAM

M

motor

U

W

V

R

S

T

E

Tensiondetecting

sensor

AI1

GND

×

×

×

Three-phase

circuit breaker

Three-phase

power supply

Loading...

Loading...