Example of Usage

V560 Series High Performance Closed-Loop Vector Inverter User manual

213

10.2.1 DIAGRAM OF CONSTANT TENSION CONTROL

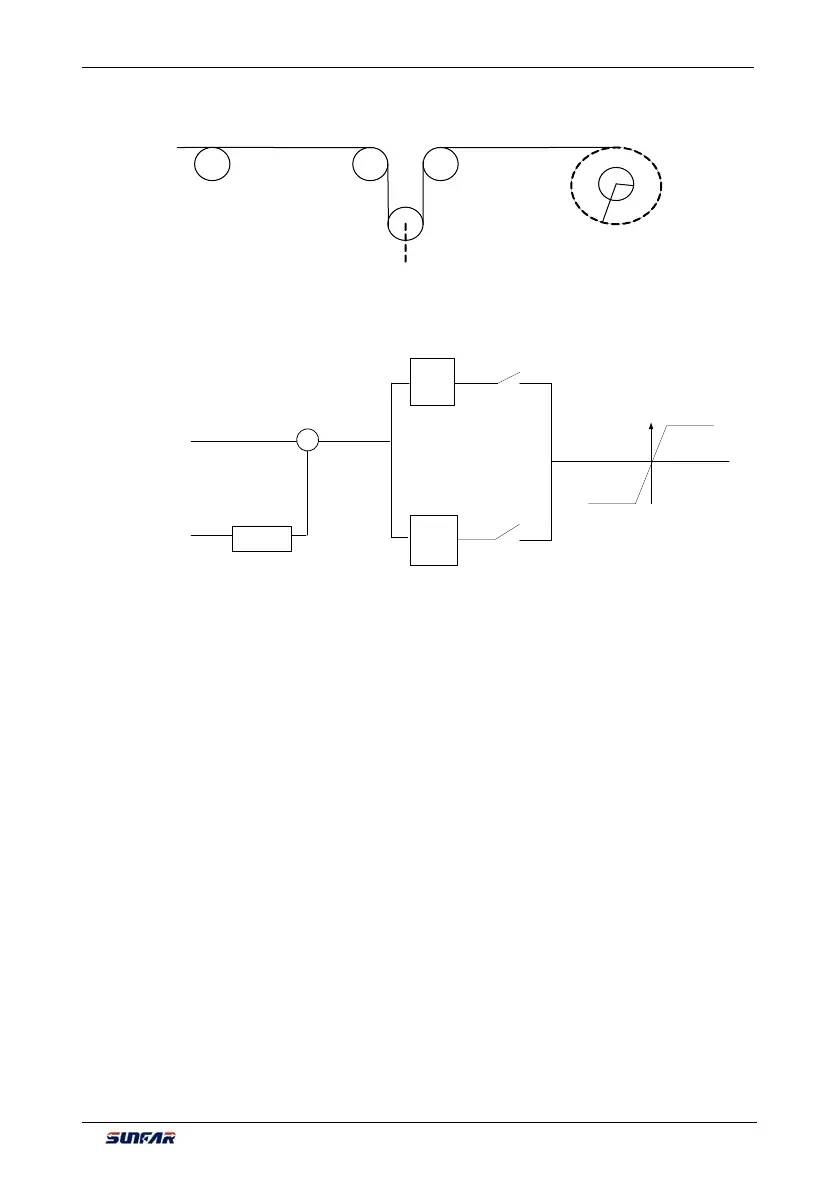

10.2.2 DIAGRAM OF CONTROL STRUCTURE

PID

Tension feedback

Torque given

Select PID parameter

depending on tension

feedback value

Offset PID output

torque given

PID

Feedback

factor

+

-

Rotational speed

limiting

Deviation

Select PID parameter

depending on tension

feedback value

10.2.3 CONFIGURATION

1. F0.0.09= 0010 Closed-loop vector controlling mode

2. F8.3.39= 1

Take care, torque model

3. F8.3.40= 8

Torque channel selects offset PID output

4. F8.3.42= 1

Time of torque ascending: 1s

5. F8.3.43= 1

Time of torque descending: 1s

6. F8.3.45= 1500 Positive rotated speed limited set on the basis of motor’s actual rated

rotated speed

7. F8.3.46= 1500 Reverse rotated speed limited set on the basis of motor’s actual rated

rotated speed

8. F8.3.47= 0000

Torque limited channel setup

9. F8.3.48= -100

Smallest torque limited:-K*R*F/T*100% R: biggest semidiameter F: tension

value setting T: torque given T (rated torque of motor output) =9550*P/N,

N: rotated speed given 100 %< K<250%

10. F8.3.50= 100 Biggest torque limited= K*R*F/T*100%

11. F9.0.00= 0101 Input together of offset PID and frequency inverter Independent PID

12. F9.0.01= 100

Offset proportion: R*F/T (rated torque of motor output)*%

13. F9.0.02= 0010

Offset PID outputs bipolar positive deviation

14. F9.0.03= 20 Proportional gain of PID in first part (relatively bigger than parameter value in

second part)

15. F9.0.04= 2 Integral time of PID in first part (relatively smaller than parameter value in

Tension

feedback

R

R:radius of full plate

:radius of empty plate

Loading...

Loading...