Operation And Simple Running Of Frequency Inverter

V560 Series High Performance Closed-Loop Vector Inverter User Manual

38

5.3 SIMPLE RUNNING OF FREQUENCY INVERTER

5.3.1 OPERATION PROCESS

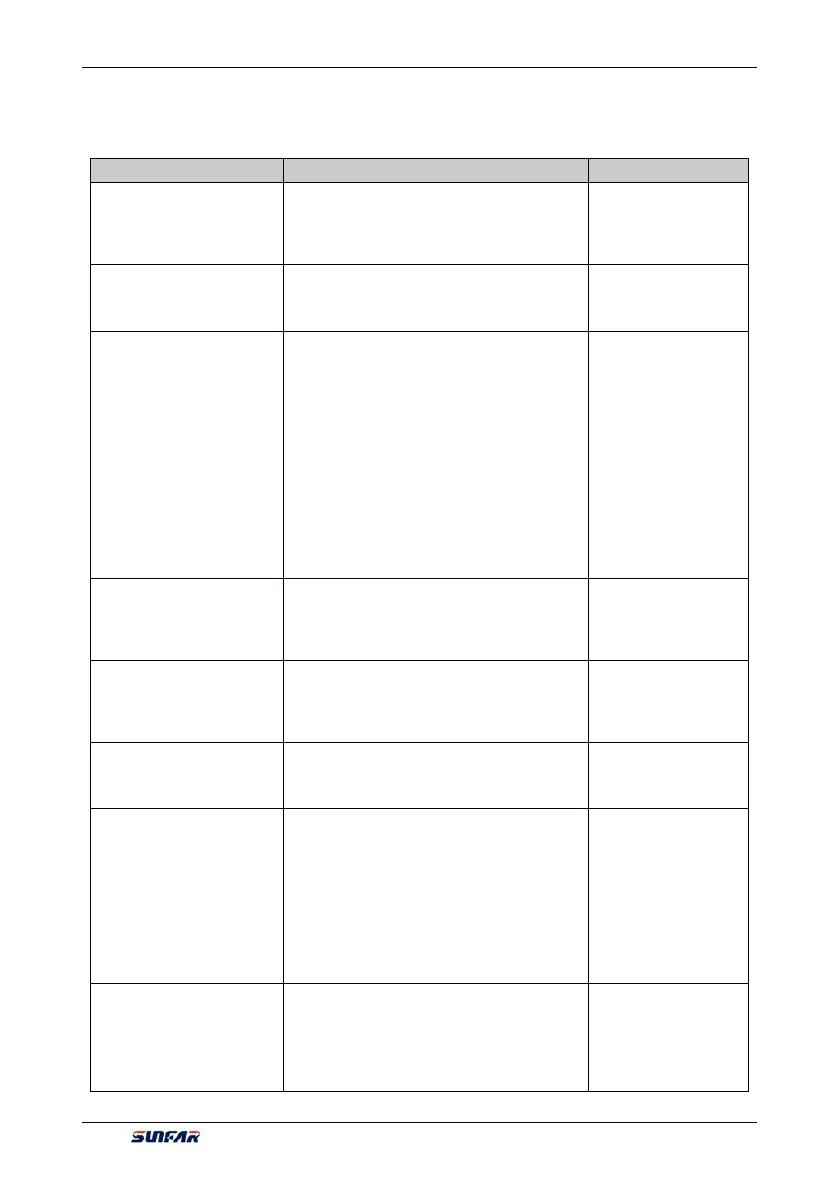

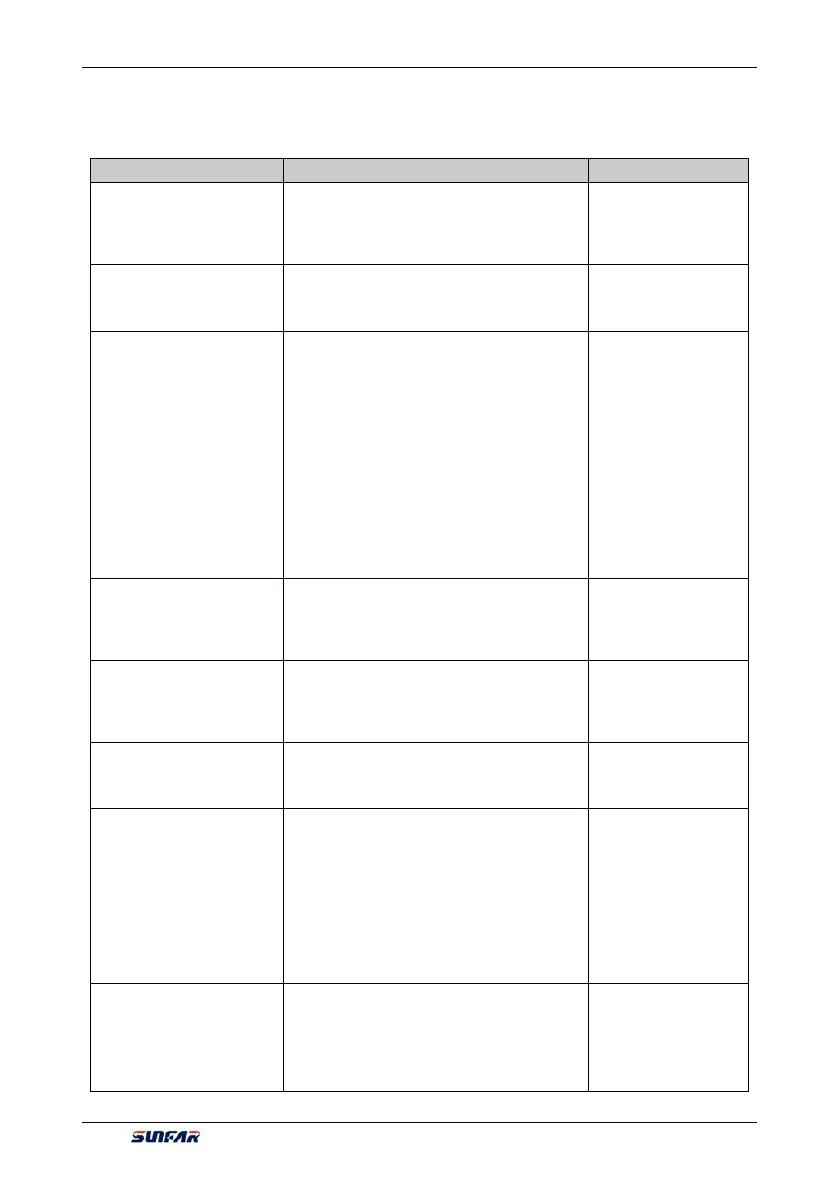

Process Operations References

Installation and operating

environment

Install frequency inverter at the place which

complies with the product technical specification.

Mainly consider ambient conditions (temperature,

humidity, etc.) and heat dissipation of frequency

inverter, etc.

Refer to Chapter 1 and 3

Wiring of frequency inverter

Wiring of main circuit input and output terminal;

Wiring of grounding wire; Wiring of switching

value control terminal, analog terminal, encoder

and communication interface

Refer to Chapter 4

Inspection before energizing

1. Make sure the voltage of input power supply is

correct and the input power supply loop is

connected with breaker; The frequency inverter

has been correctly and reliably grounded;

2. The power cord has been correctly connected

with R, S, T power input terminal of the

frequency inverter;

3. The output terminal of the frequency inverter U,

V, W is correctly connected with the motor;

4. The encoder is correctly connected with PG

card;

5. The terminal block is correctly connected and

all the external switches are correctly preset;

6. The motor is empty-load (the mechanical load

is disconnected with motor).

Refer to Chapter 4

Inspection in energizing

Whether the frequency has abnormal sound,

smoking and peculiar smell, etc; And the

operation panel displays normally without fault

alarm information. If there are abnormalities,

please cut off the power supply immediately.

Refer to chapter 3 and 5

Parameter initialization

When the frequency inverter is operated initially,

changed internal control panel or controlled motor,

it is recommended to conduct the next operation

and setting after setting function code F0.0.07 and

conducting parameter initialization.

Refer to F0.0.07

parameter function

Correctly input the name plate

of the motor

Make sure the name plate parameter of the motor

is input correctly and carefully checked by users;

Otherwise, serious problems may be occur in

operation.

Refer to F2.0.00 ~

F2.0.05 motor 1 and

F2.1.26 ~ F2.1.30 motor

2 parameter set

Protection parameter setting

for motor and frequency

inverter

Correctly set the limit parameter, protection

parameter and protection mode of the frequency

inverter and the motor, mainly including: the

maximum frequency, upper frequency limit, motor

overload protection, external fault input, fault relay

output and encoder disconnection protection, etc.

Refer to F1.1.39 ~

F1.4.52 parameter set

for stable operation,

F3.1.12 ~ F3.1.35

parameter set for

multifunctional terminal

output,

F4.3.36~F4.3.50

parameter set for analog

input disconnection

detection

Automatic learning

The automatic learning for motor parameters

should be conducted before selecting vector

control mode for the first operation so as to get

accurate electric parameters of the controlled

motor. If the motor is rotating, please conduct after

the motor is completely stopped.

Refer to F2.2.53

parameter set for

parameter determination

Loading...

Loading...