You can access the Service Manual (http://www.universal-robots.com/support) for more on how to

perform inspections.

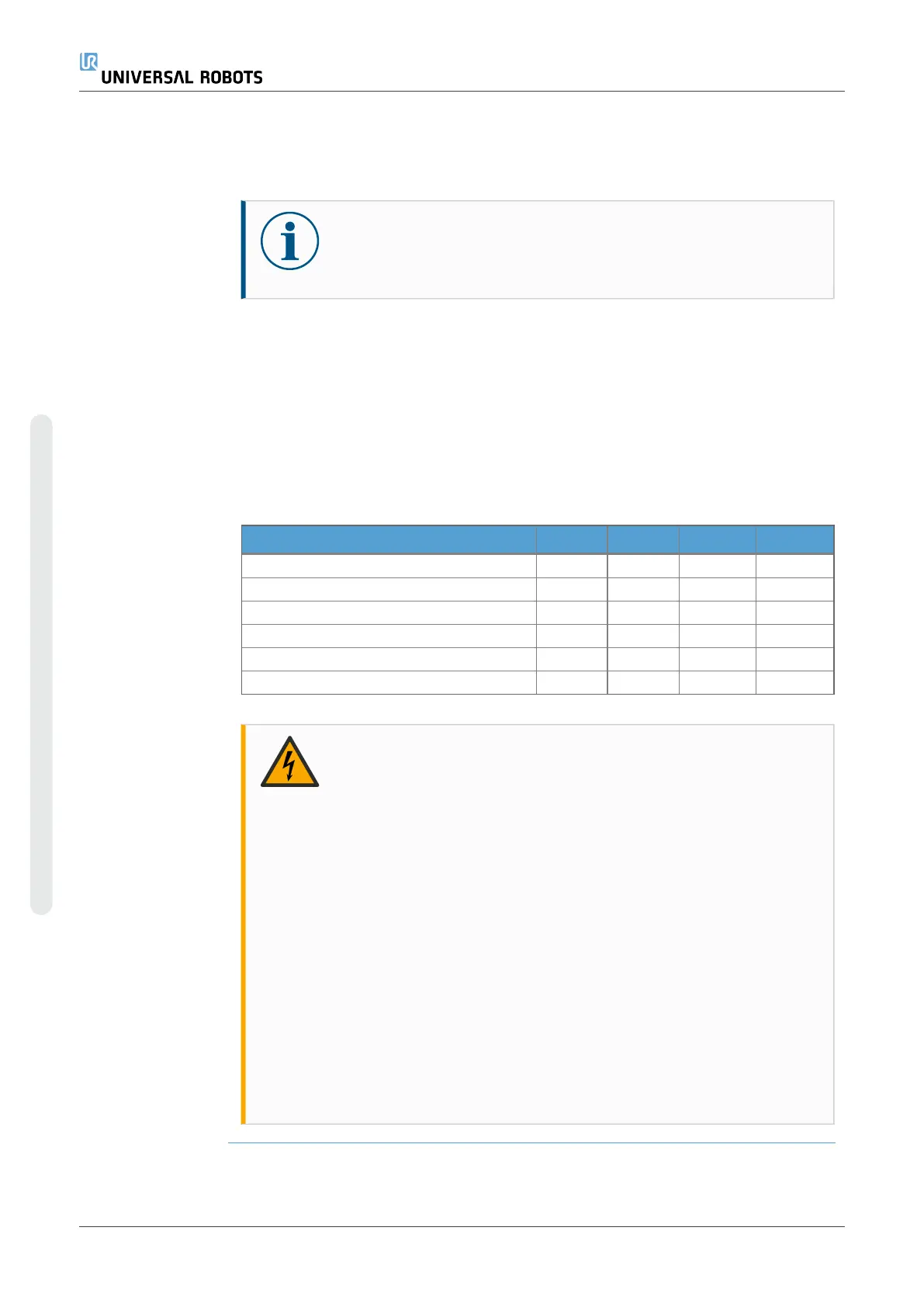

Inspection action type Timeframe

Monthly Biannually Annually

1 Check Emergency stop on Teach Pendant F ✘

2 & 3 Check Backdrive mode F ✘

Check Freedrive mode F ✘

4 & 5 Check Teach Pendant cable and

connector

V ✘

6 Check and clean air filters on Control Box V ✘

V = Visual inspection F = Functional inspection

Control Box Visual Inspection

1. Disconnect the power cable from Control Box.

2. Check for any dirt/dust outside the Control Box.

•

Clean with ESD vacuum cleaner if needed.

NOTICE

Using compressed air to clean inside the Control Box can damage components.

•

Do not use compressed air to clean inside the Control Box.

2.7. Disposal and Environment

Universal Robots e-Series robots must be disposed of in accordance with the applicable national

laws, regulations and standards.

Universal Robots e-Series robots are produced with restricted use of hazardous substances to

protect the environment; as defined by the European RoHS directive 2011/65/EU. These

substances include mercury, cadmium, lead, chromium VI, polybrominated biphenyls and

polybrominated diphenyl ethers.

Fee for disposal and handling of electronic waste of Universal Robots e-Series robots sold on the

Danish market is prepaid to DPA-system by Universal Robots A/S. Importers in countries covered by

the European WEEE Directive 2012/19/EU must make their own registration to the national WEEE

register of their country. The fee is typically less than 1€/robot. A list of national registers can be

found here: https://www.ewrn.org/national-registers.

UR16e 62 User Manual

2.Part I Hardware Installation Manual

Copyright © 2009–2024 by UniversalRobotsA/S. All rights reserved.

Loading...

Loading...