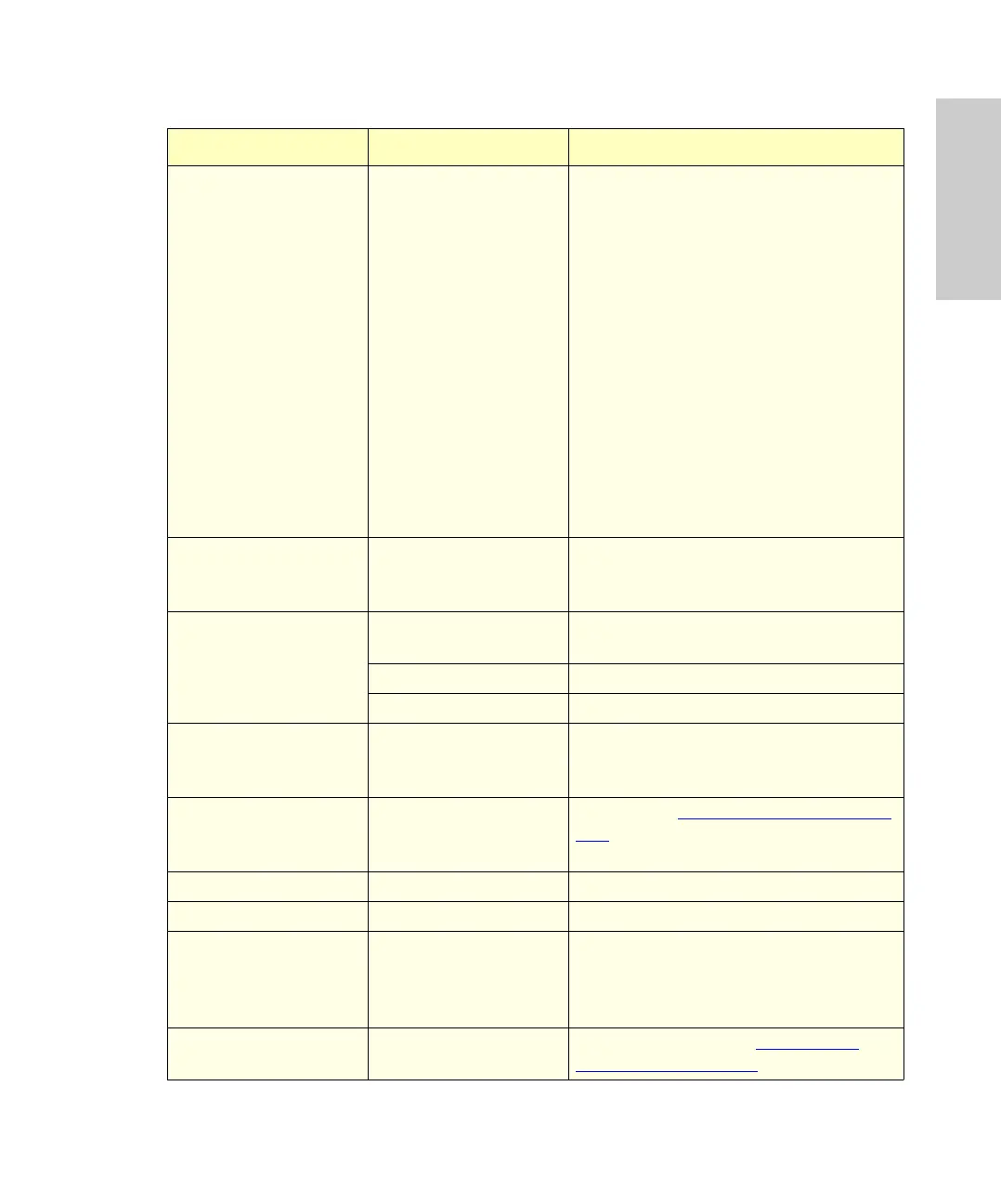

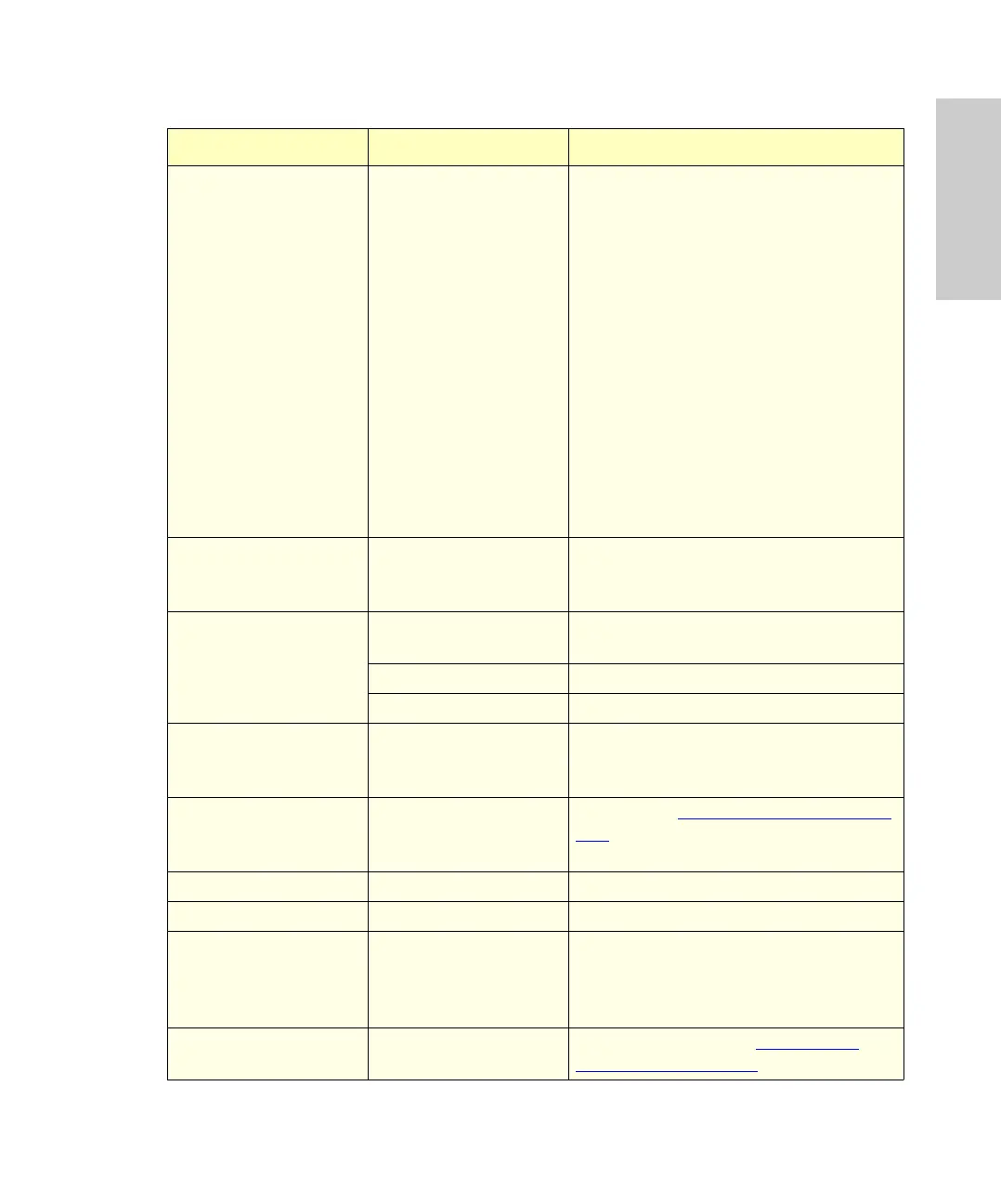

Troubleshooting Tables 149

6

Autosampler does not

run (fan and front

panel light on)

Autosampler not

connected to

controller

Ensure IEEE cable is properly

connected to controller. Verify that

IEEE-488 addresses (if IEEE-488

communication is in use) are properly

set.

• If properly connected and IEEE-488

addresses are correct, turn off the

autosampler and controller and

disconnect the cable. Turn on the

autosampler and verify that it is

calibrated and operates under its

own control.

• If autosampler operates properly,

refer to the controller operator’s

manual for troubleshooting

information.

Autosampler does not

run (fan and front

panel light on)

Power failure Reset the autosampler and resume

operation.

Sample compartment

door opened

Close sample compartment door. If

problem continues, contact Waters.

Sample carriage error Contact Waters.

Defective circuit board Contact Waters.

Leak from fluid system

(needle, injector, seal

pak, fluid pack)

Loose or overtight-

ened compression

fitting

Verify fittings and ferrules for

under/overtightening and wear.

Replace if necessary.

Defective valve seals Test valves (Section 6.4.2, Valve Leak

Tes t) and replace as required (call

Waters).

Defective seal pak Replace seal pak (call Waters).

Defective fluid pack Replace fluid pack (call Waters).

Damaged needle Purge the autosampler to unplug the

needle. If problem continues, replace

the needle assembly and seal pak (call

Waters).

Blocked or damaged

syringe

Replace syringe (see Section 5.2,

Replacing the Syringe).

Table 6-8 Autosampler Troubleshooting (Continued)

Symptom Possible Cause Corrective Action

Loading...

Loading...