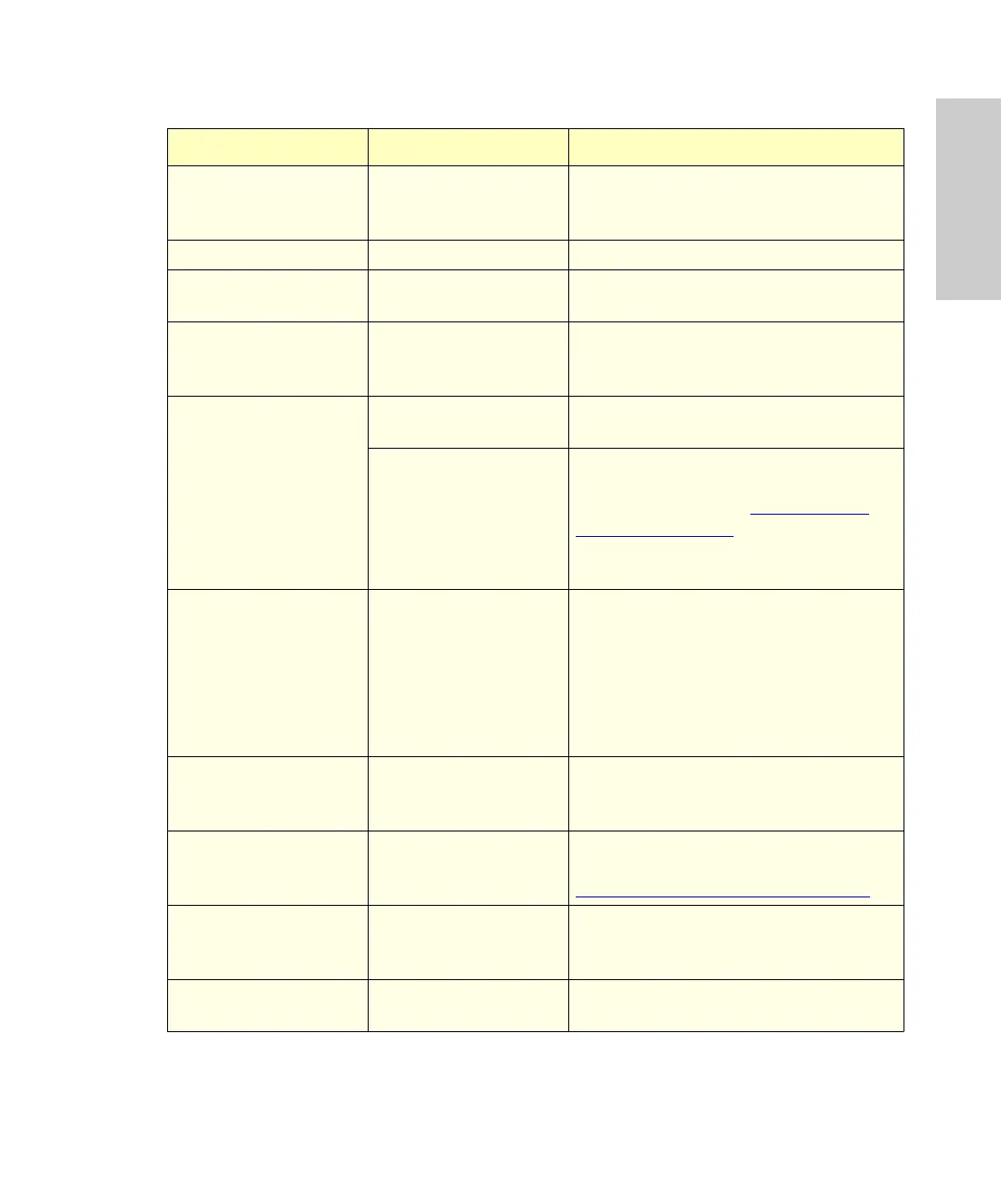

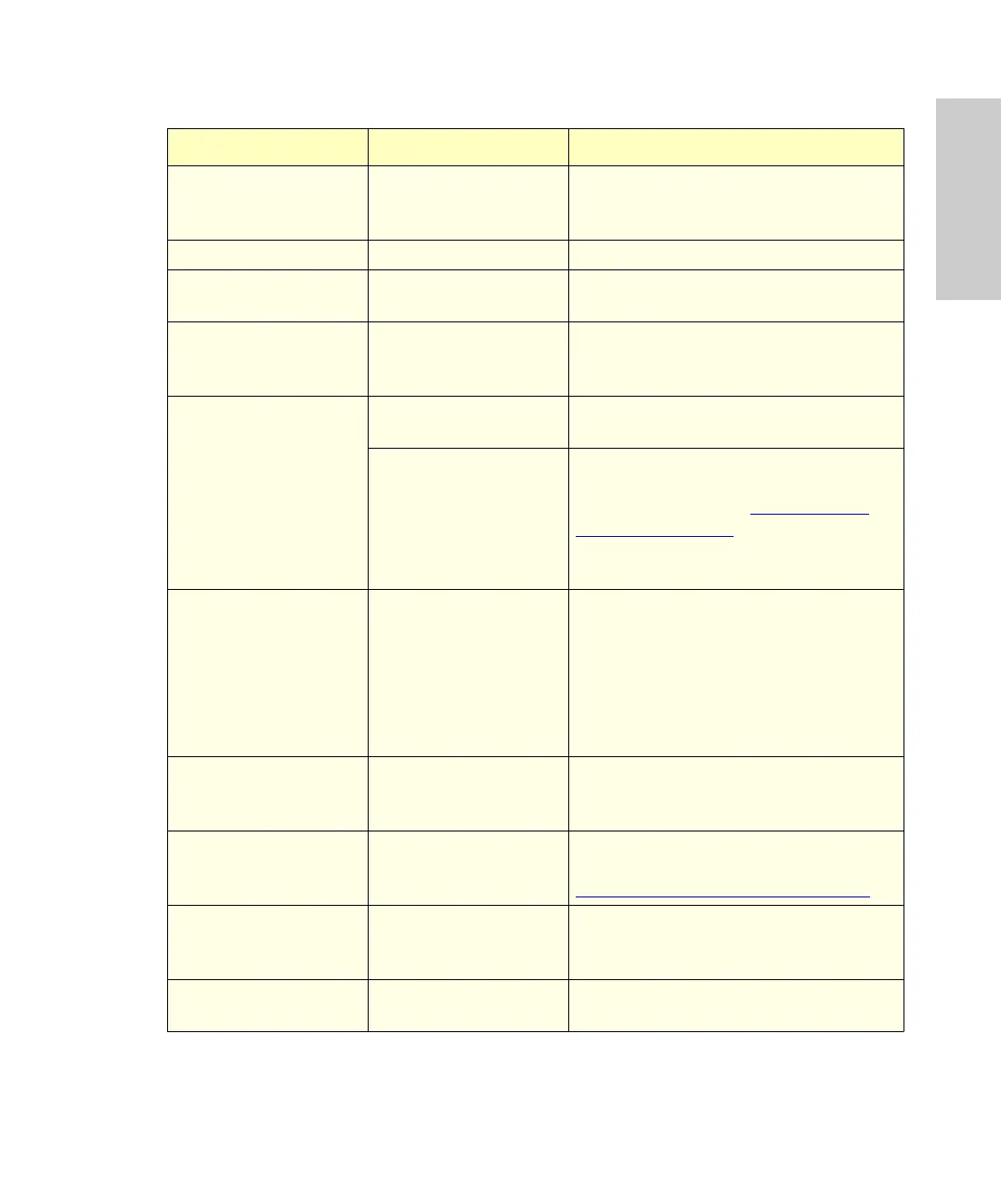

Troubleshooting 150

6

Leak from needle

wash system

Loose or overtight-

ened compression

fitting

Verify fittings and ferrules for

under/overtightening and wear.

Replace if necessary.

Defective fluid valve Replace fluid valve (call Waters).

Defective needle wash

pump

Replace needle wash pump (call

Waters).

Autosampler is

siphoning solvent from

needle wash reservoir

Lower the needle wash solvent

reservoir.

Sample injection

problem (such as

sample not being

injected, abnormal

peak shape)

Defective injection

valve

Purge the autosampler. If problem

continues, repair/replace the valve.

Blocked needle due to

particles in sample

Purge the autosampler to unplug the

needle. Ensure sample and solvent are

properly filtered (see Section 4.2.1,

Preparing Samples) to prevent further

blockages. If the problem continues,

replace the needle assembly.

Air bubble in syringe

or sample loop

assembly

Purge the autosampler.

If air bubbles are repeatedly being

drawn in, verify that a vacuum is not

being created when needle pierces the

self-sealing septum (indicating seal is

too tight around needle). Inject from

the sample vial without a cap in place.

Injection from empty

sample vial

Compare sample vial entry and vial

position. Enter correct sample vial

number.

Insufficient sample in

vial

Ensure minimum sample volume

requirement is in the vial (see

Appendix D, Selecting Sample Vials

).

Sample injection

problem (continued)

Cap is on too tight on

the self-sealing

septum

Loosen the cap.

Sample too viscous Dilute sample or decrease syringe

draw speed rate.

Table 6-8 Autosampler Troubleshooting (Continued)

Symptom Possible Cause Corrective Action

Loading...

Loading...