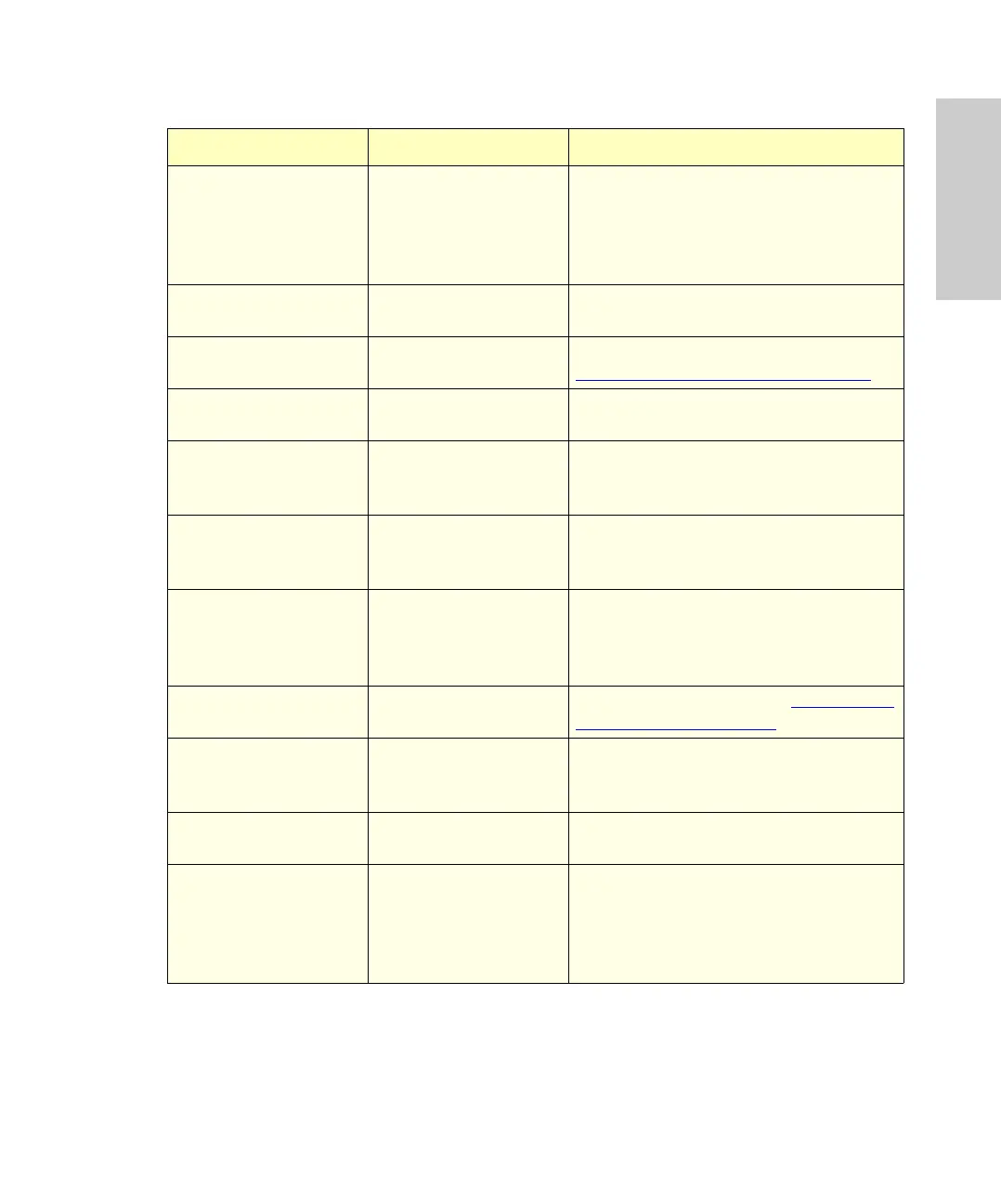

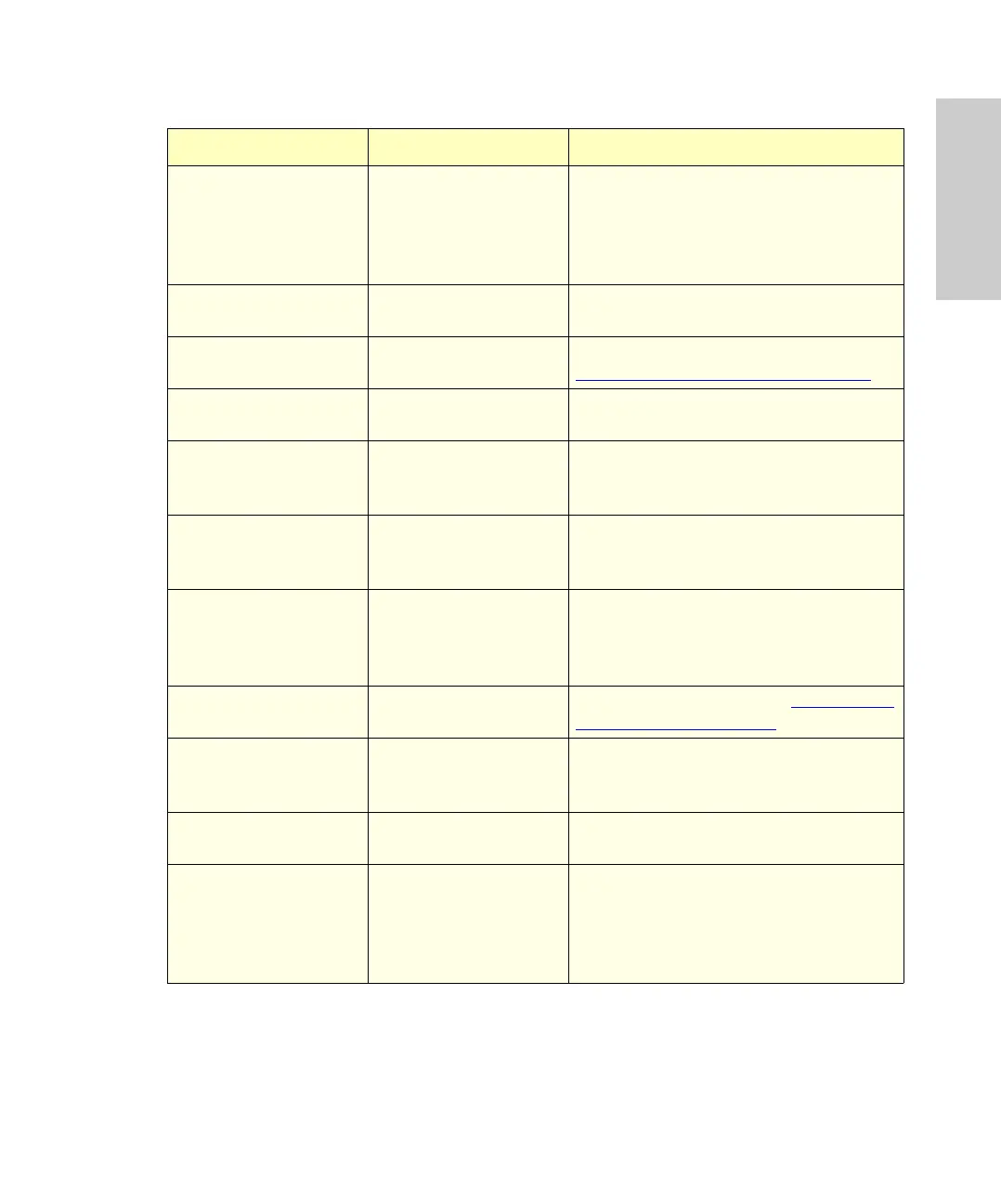

Troubleshooting Tables 151

6

Sample injection

problem (continued)

Vial septum not being

pierced

Re-inject from the sample vial with a

cap in place. Inspect if a hole is being

made by the injector. If no hole is

made, there is a problem with the

injector/needle.

Misaligned sample

transport system

Call Waters.

Defective injector

seals

Replace injector seals (see

Section 5.3, Replacing the Seal Pak

).

No solvent flow

through injector

Autosampler not

connected to pump

Attach fluid lines to pump (see pump

operator’s manual).

Autosampler stuck in

purge (valve 1 closed)

Restart operation to reposition valve. If

problem continues, repair/replace

valve (call Waters).

Blocked injection valve Purge the autosampler. If problem

continues, repair/replace the injection

valve.

Leak within autosam-

pler or prior to

autosampler

Check for leaks. Tighten loose fittings.

If leaks continue, verify fittings and

ferrules within autosampler for wear.

Replace if necessary.

High system pressure

due to autosampler

Blocked in-line filters Replace filter inserts (see Section 5.4,

Replacing In-Line Filters).

Blocked needle due to

particles in sample

Refer to the Corrective Action under

the “Sample not being injected”

symptom listed above.

Blocked injection valve Purge the autosampler. If problem

continues, repair/replace the valve.

Sample not miscible

with mobile phase

To verify solubility, place sample and

mobile phase in a test tube and

observe if the sample dissolves. If

necessary, further dilute the sample or

change the mobile phase.

Table 6-8 Autosampler Troubleshooting (Continued)

Symptom Possible Cause Corrective Action

Loading...

Loading...