Troubleshooting 152

6

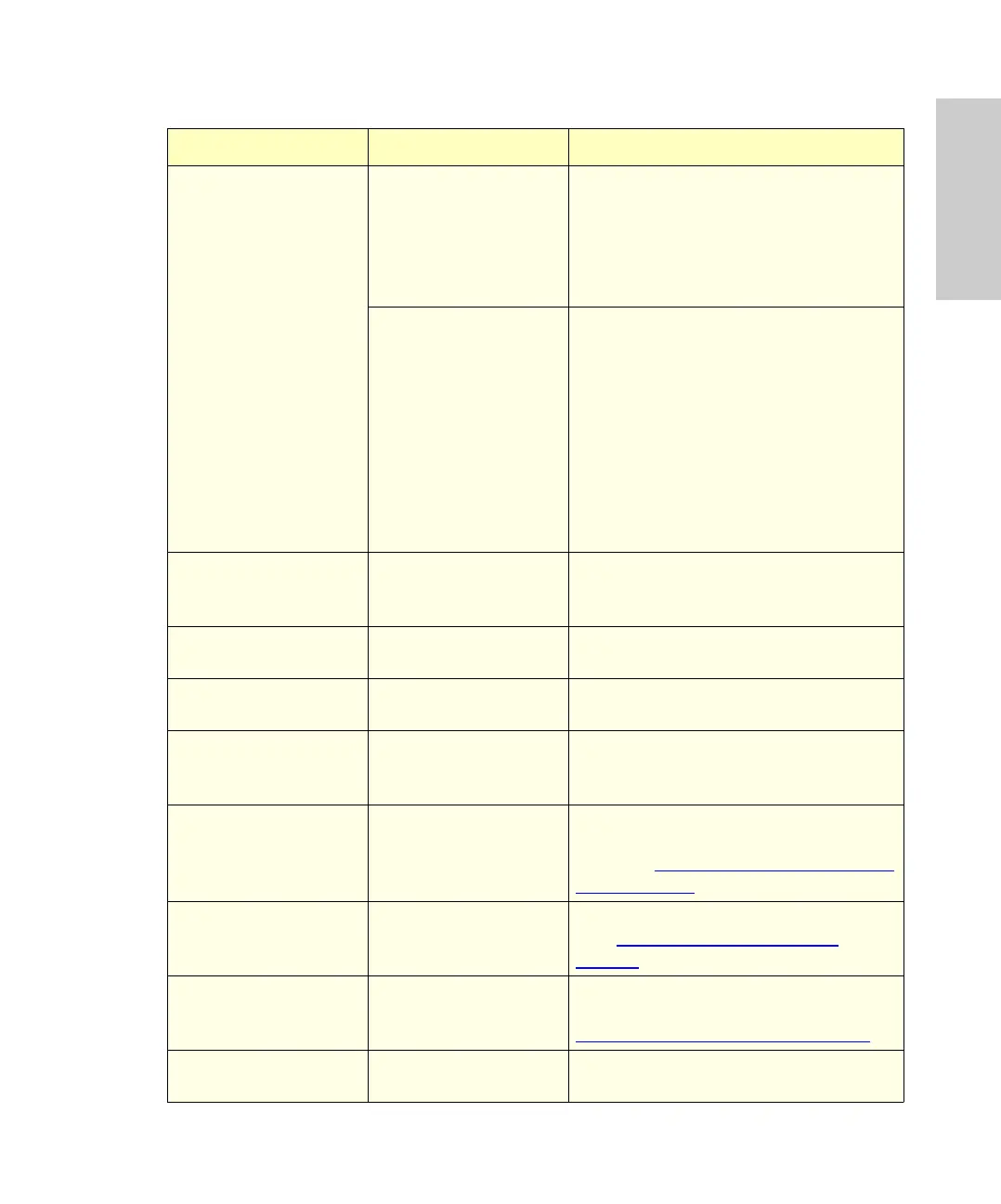

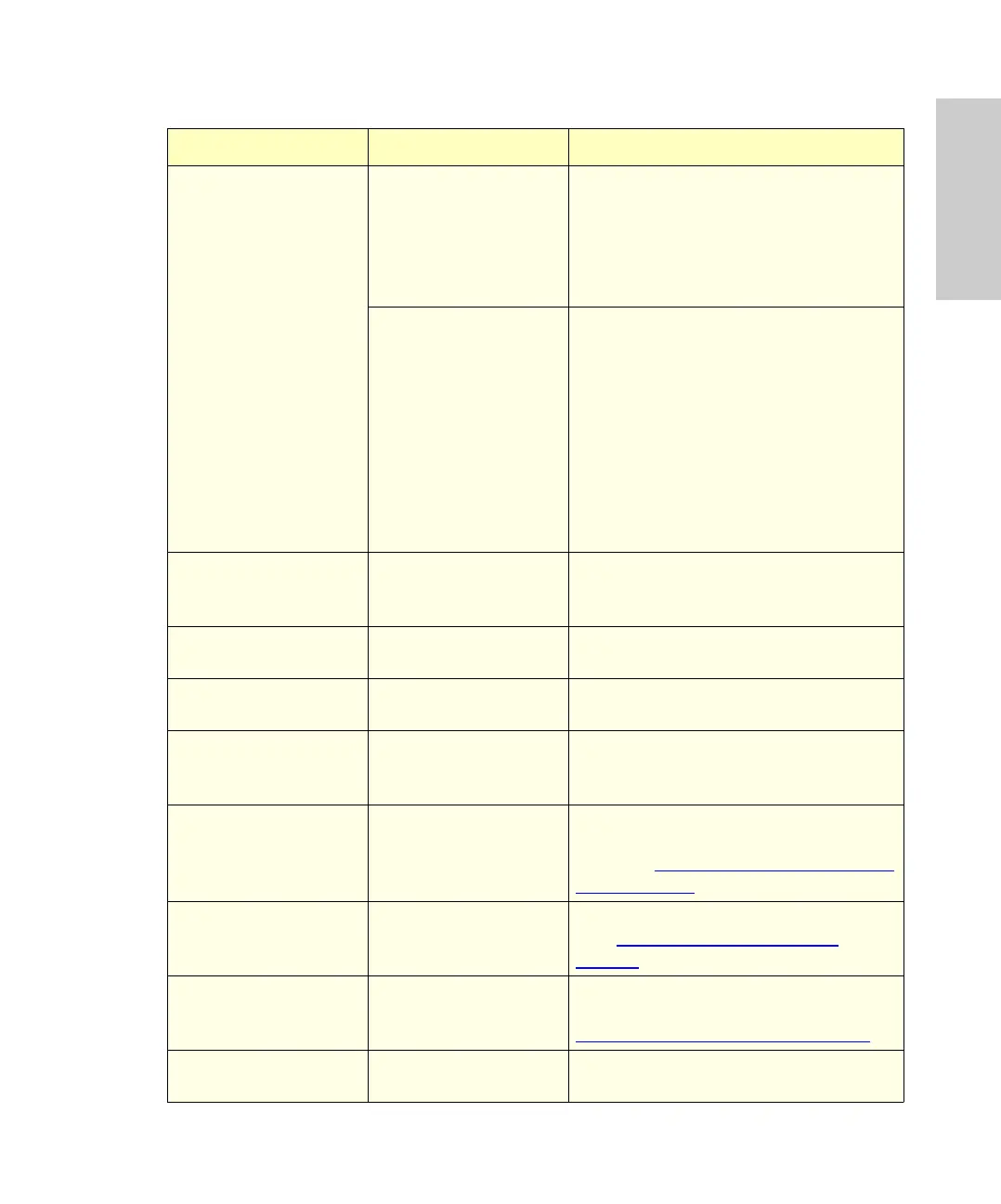

Sample carryover Sample injection

problem

To verify the problem, test with blank

injections of solvent after a sample

injection. If the carryover problem

occurs after a sample injection, this

may be due to a problem with the

needle wash system (see below).

Needle wash system

problem (due to loss

of prime, empty

solvent reservoir,

contaminated frits, or

defective needle wash

pump)

Verify these potential problem areas

and perform one of the following:

• Empty solvent reservoir – Refill

the needle wash reservoir.

• Loss of prime – Reprime the

needle wash system.

• Contaminated frits – Replace seal

pak.

• Defective needle wash pump –

Call Waters.

Injection from wrong

sample vial

Incorrect sample vial

number specified

Compare sample vial entry and vial

position. Enter correct sample vial

number in autosampler.

Sample vial

mislabeled

Verify information on sample vial.

Change label if necessary.

Misaligned sample

transport system

Call Waters.

Incorrect sample

volume injected

Incorrect injection

volume specified

Compare injection volume value and

vial position. Enter correct injection

volume value in autosampler.

Incorrect syringe size

value specified on

configuration menu

Compare syringe size value and

installed syringe. Enter correct syringe

size (see Section 3.6.3, Entering Hard-

ware Changes).

Incorrect syringe

installed in fluidic

system

Replace with appropriate size syringe

(see Section 5.2, Replacing the

Syringe).

Insufficient sample in

vial

Ensure minimum sample volume

requirement is in the vial (see

Appendix D, Selecting Sample Vials

).

Leaky syringe Repair/replace syringe (see autosam-

pler operator’s manual).

Table 6-8 Autosampler Troubleshooting (Continued)

Symptom Possible Cause Corrective Action

Loading...

Loading...