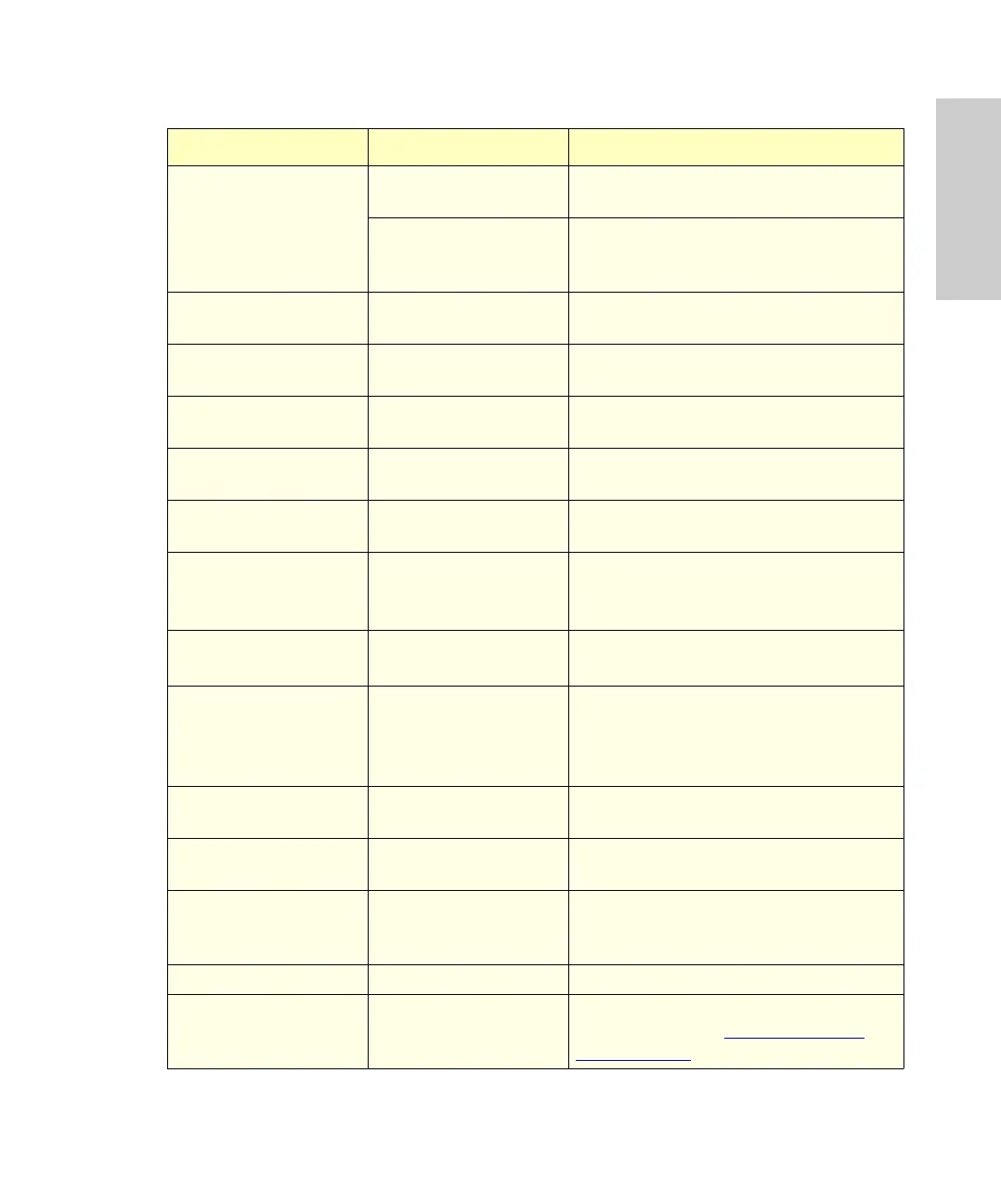

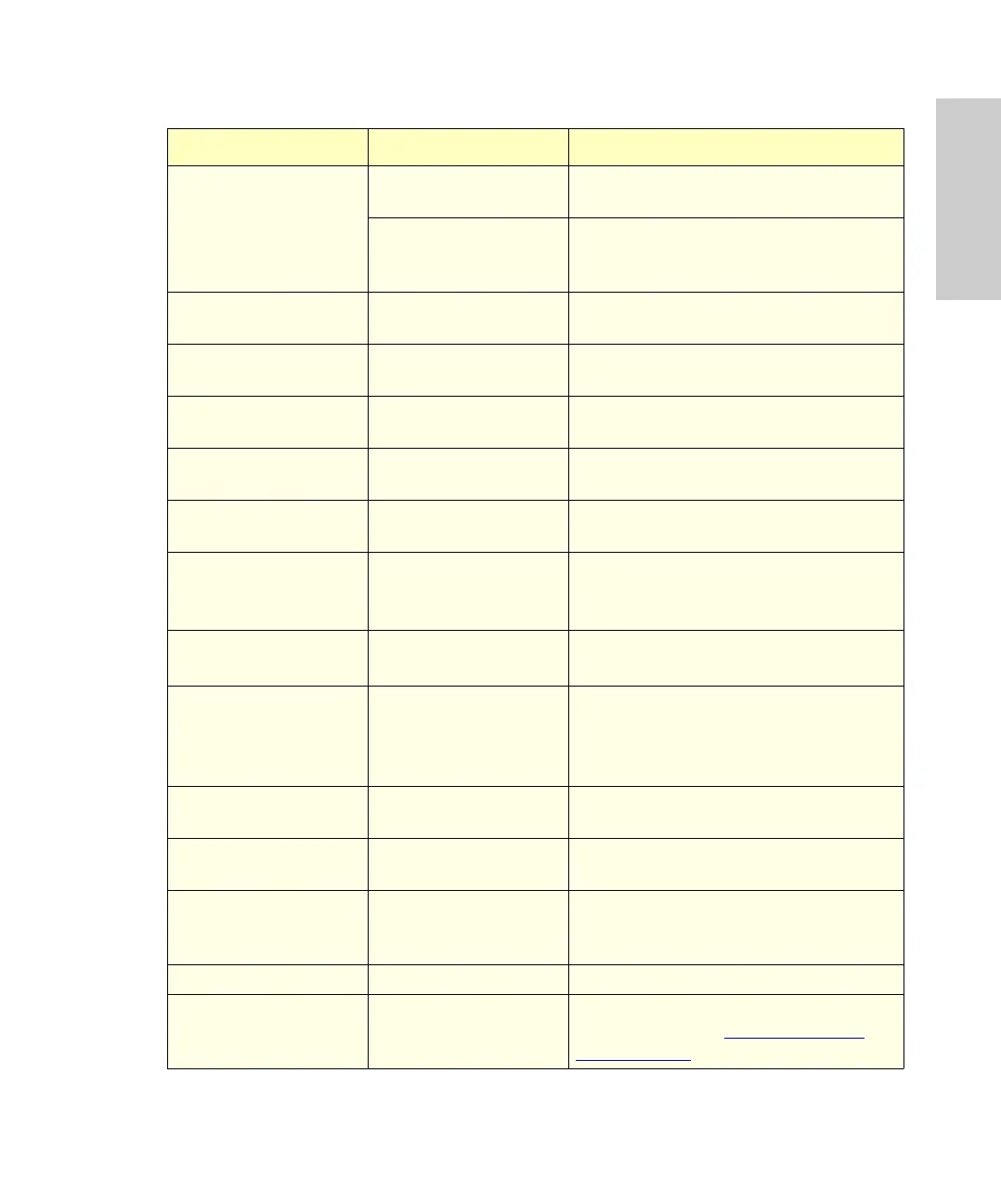

Troubleshooting Tables 153

6

Incorrect sample

volume injected

(continued)

Sample too viscous Dilute sample or decrease syringe

draw speed rate.

Vacuum created in vial Make injections without a cap in place,

remove excess sample from the vial, or

loosen cap on the self-sealing septum.

Vials repeatedly break Incorrect vials being

used

Use Waters vials.

Incorrect caps being

used

Use Waters caps.

Caps not put on

properly

Ensure that caps are on properly.

Needle or injector

malfunction

Call Waters.

Misaligned sample

transport system

Call Waters.

Needle bent Solid cap not removed

from sample vial

Remove sample vial cap and replace

with a septum and cap.

Replace the autosampler needle.

Incorrect vials being

used

Use Waters recommended vials.

Replace the autosampler needle.

Septum too resistant Ensure that only one septum is being

used at a time.

Replace the autosampler needle (see

autosampler service manual).

Misaligned sample

transport system

Call Waters.

Heater/cooler fails to

reach the set point

Frost prevents cooling Defrost sample compartment.

Exterior or sample

compartment fans not

working

Replace fan (call Waters).

Fan filter dirty Clean fan filter.

Insufficient air flow Ensure sufficient space behind

autosampler (see Section 2.1, Site

Requirements).

Table 6-8 Autosampler Troubleshooting (Continued)

Symptom Possible Cause Corrective Action

Loading...

Loading...