Maintenance

1132−2/A1

Winterthur Gas & Diesel Ltd.

13/ 14

Note: To prevent bearing shell movement into the bearing girder, hold the

bearing shell and move it slowly into the bearing girder (on fuel side) at

the rope ends.

8) Carefully move the bearing shell into the bearing girder (on the fuel side).

9) Carefully put the Allen screws into the bearing shell.

10) Release the pressure at HP oil pump (94931) to fully lower the crankshaft.

11) Remove the hydraulic rams 94936, 94936 and the hydraulic pump 94931.

6.2 Main Bearing Cover −

Installation

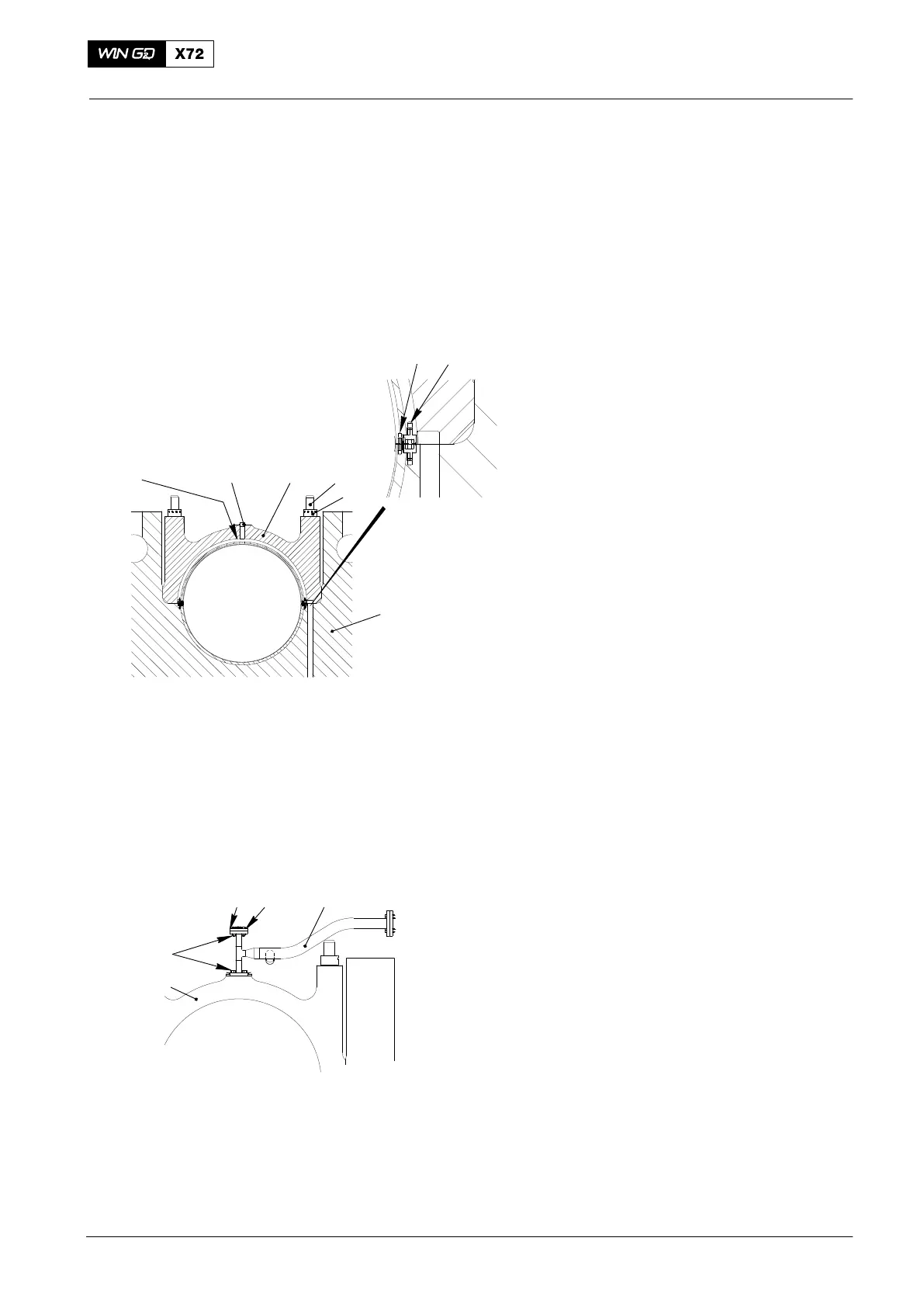

1) Make sure that the work area and all

tools and equipment are clean and in

good condition.

2) Remove all plugs from oil bore (OB).

3) Use the applicable equipment to get

the bearing cover in the correct position

above the crankshaft as follows:

D For bearing covers No. 2 to No. 8

refer to paragraph 2.

D For bearing cover No. 1, refer to

paragraph 3).

Note: The top bearing shell is attached

to the cover with two Allen screws

(2, Fig. 27). The spring dowel pins

(1) help to get the bearing cover (3)

in position during the installation.

4) Clean all surfaces on the the bearing

cover (3) and the bearing girder (5).

5) Lower the bearing cover (3) on to the

bearing girder (5). Make sure that the

two spring dowel pins engage correctly.

6) Apply tension to the elastic studs (4),

refer to 1132−1.

7) Tighten the round nuts (7).

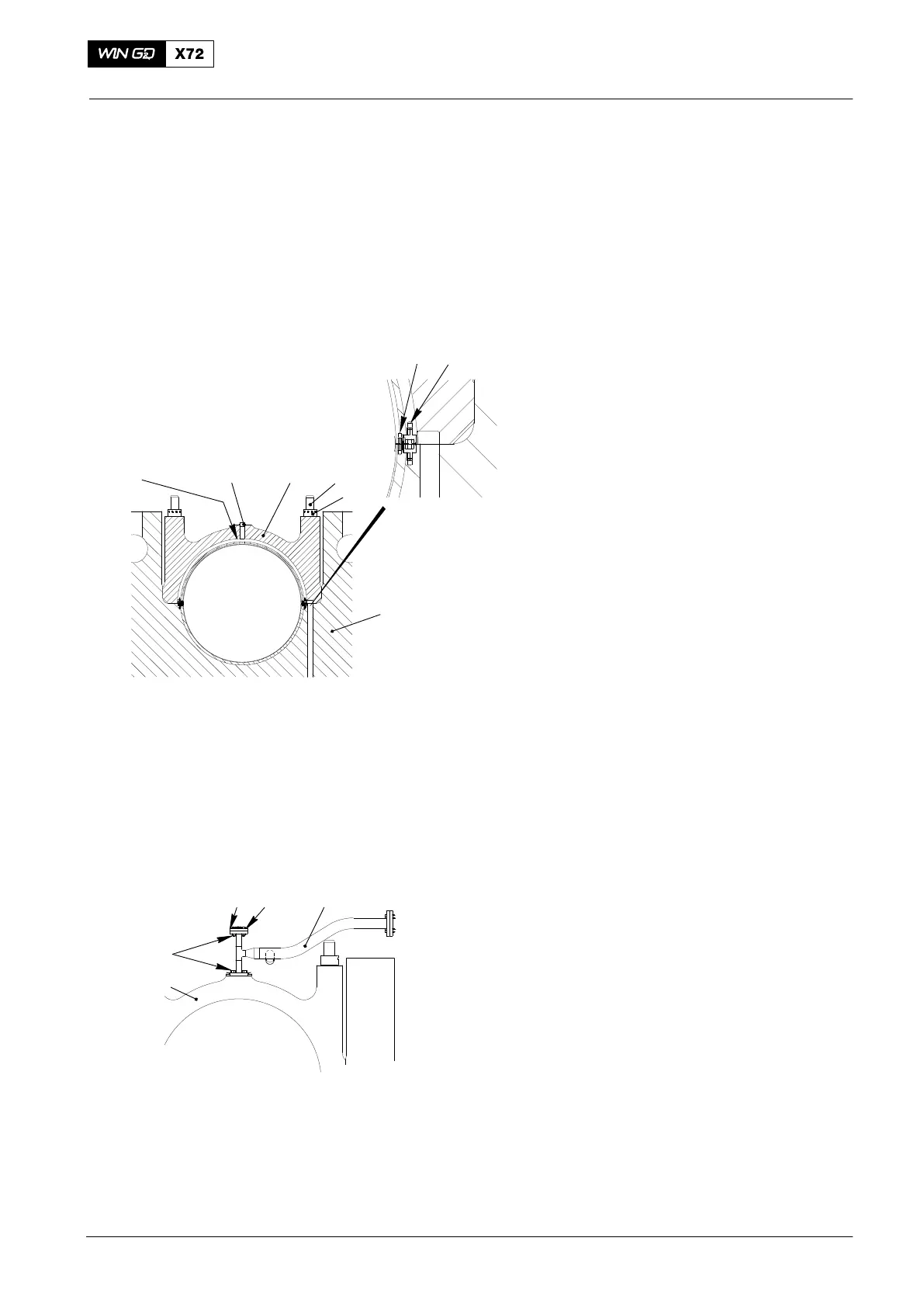

8) Clean the pipes (1, Fig. 28).

9) Install the pipes (1), their gaskets and

new tab washers (4).

10) Tighten the screws (3).

11) Lock the screws (3) with the new tab

washers (4).

12) Remove all tools and equipment from

the work area.

13) Measure the bearing clearance and

compare the value measured in

paragraph 2, with the value given in the

Clearance Table 0330−1.

Note: If the clearance is in the limits

given, the bearing can be removed

and installed again.

2015

Main Bearing − Removal and Installation

WCH02321

1

OB

1

WCH02325

2

2

34

5

3, 4

6

6

Fig. 27

Fig. 28

7

5

Loading...

Loading...