Maintenance

3303−2/A1

Winterthur Gas & Diesel Ltd.

5/ 7

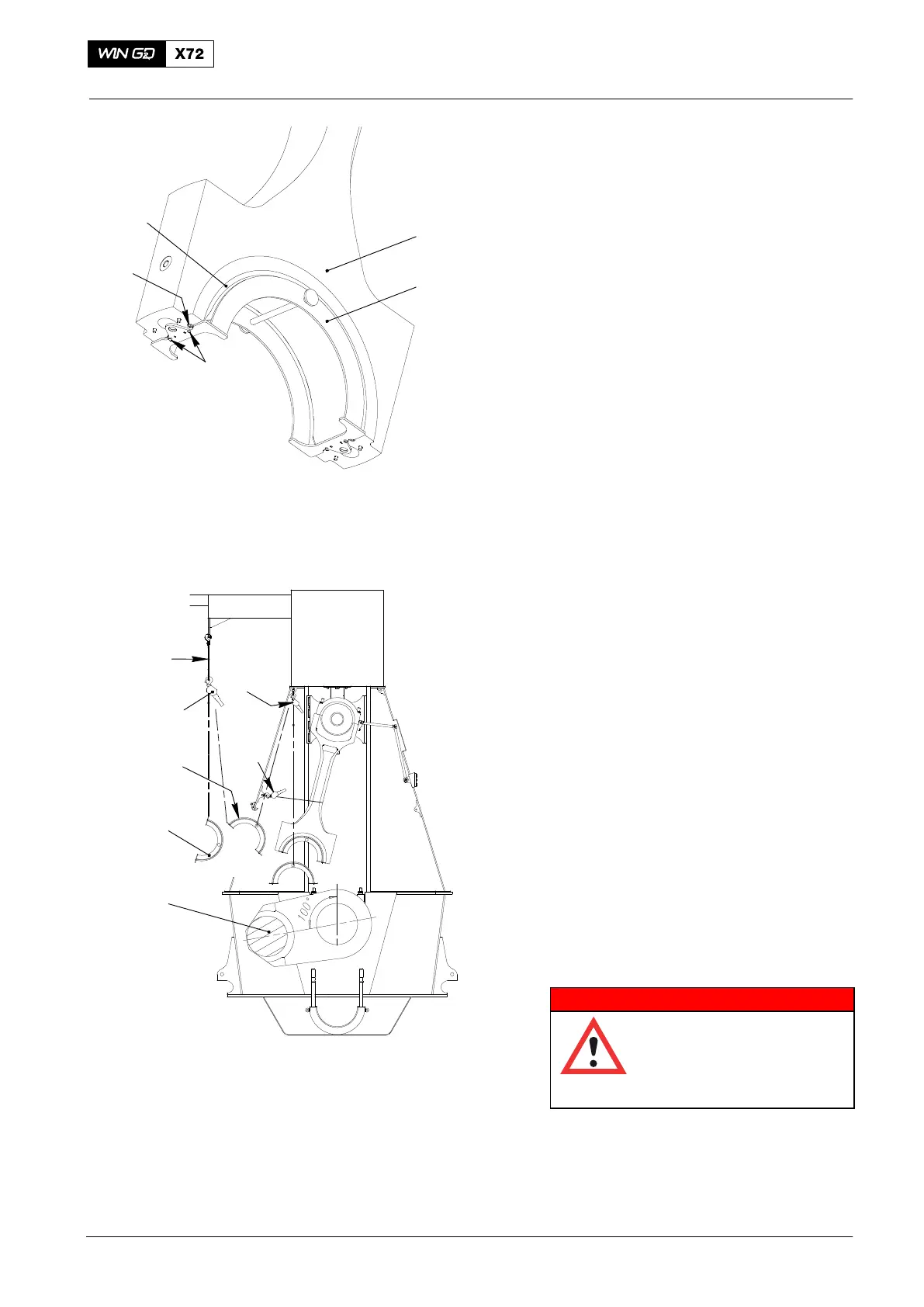

6. Top Bearing Shell −

Installation

1) Clean the seating surface of the

connecting rod (1, Fig. 9) and the

bearing shell (10).

2) Put the bearing shell (1) on the console

frame (94326)

3) Tighten the four screws (11).

4) Clean the seating surface of the

connecting rod (1) and the bearing

shell (10).

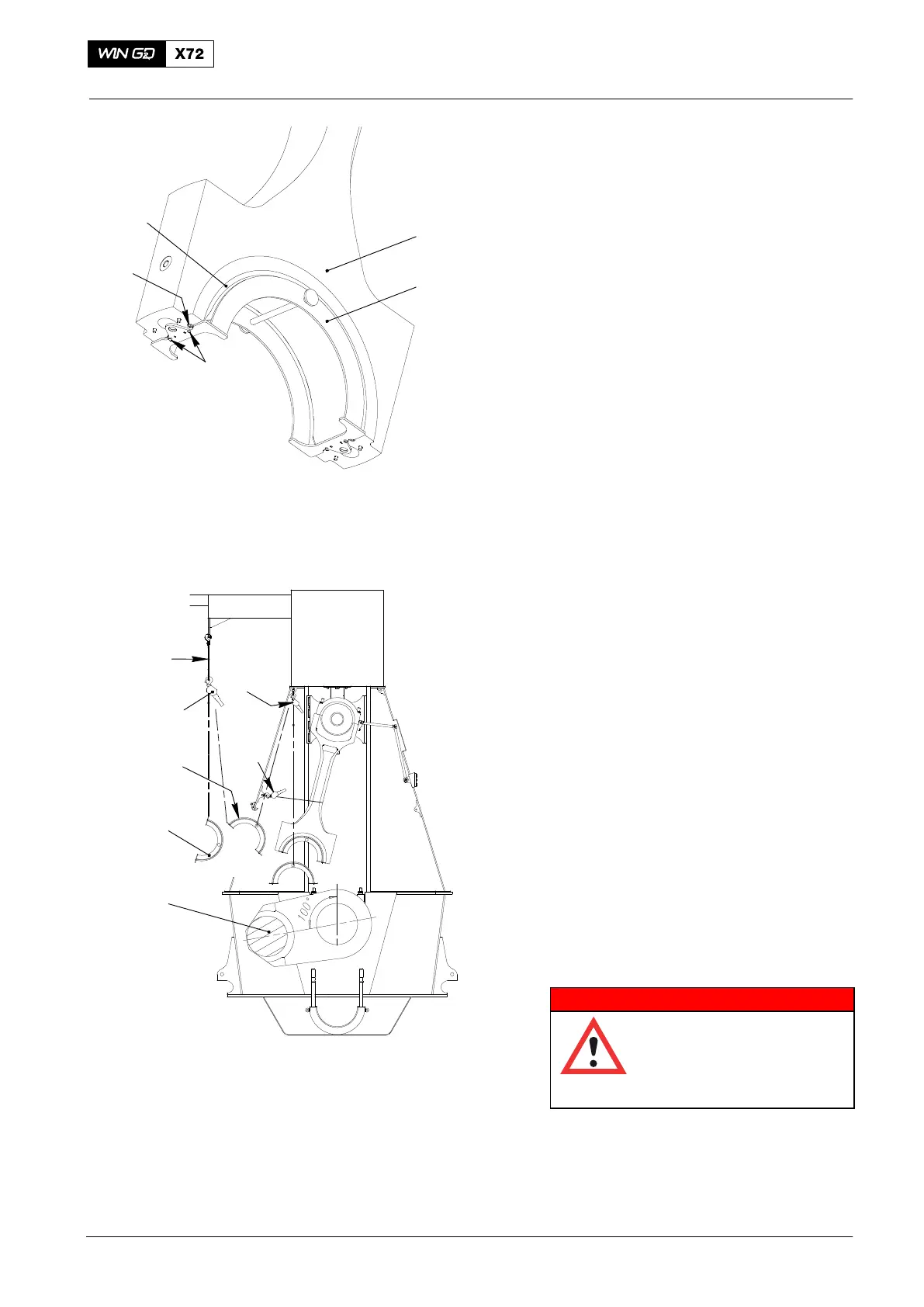

5) Attach the manual ratchet (H4, Fig. 10)

to the console frame (94326).

6) Operate the manual ratchet (H4) to lift

the console frame (94326) into position.

7) Attach the manual ratchets (H1, H5) to

the console frame (94326).

8) Remove the manual ratchet (H4).

9) Put oil on the surface of the bearing

shell (10).

10) Operate the manual ratchets (H1, H5)

to move the console frame (94326) and

bearing shell (10) into position.

Note: Make sure that the distance

between each end of the bearing

shell and the connecting rod rod is

the same.

11) Attach the bearing shell (10, Fig. 9) to

the connecting rod (1) with the two

screws (12).

12) Remove the console frame (94326).

13) Make sure that the surface of the crank

pin (2, Fig. 10) is in a satisfactory

condition.

14) Put oil on the crank pin.

WARNING

Injury Hazard: Before you

operate the turning gear,

make sure that no

personnel are near the

flywheel.

15) Use the turning gear to move the crank

to TDC. Make sure that there is no load

at the points (X, Fig. 5).

16) Remove the two supports (94322).

2015

Bottom End Bearing − Removal, Inspection and Installation

WCH02423

1

11

94326

10

12

Fig. 9

Fig. 10

WCH02423

H4

94326

H3

10

94019B

H5/H1

2

Loading...

Loading...