Maintenance

8752−1/A1

Winterthur Gas & Diesel Ltd.

7/ 11

3. Sealing Faces − Grind

To remove deep notches of more than

0.1 mm, use emery cloth of medium to

coarse grain (30 to 80 CAMI). For finish

grinding, use emery cloth with fine or

ultra-fine grains (100 to 600 CAMI).

To get a clean and smooth finish on the

pipe, do the procedure that follows:

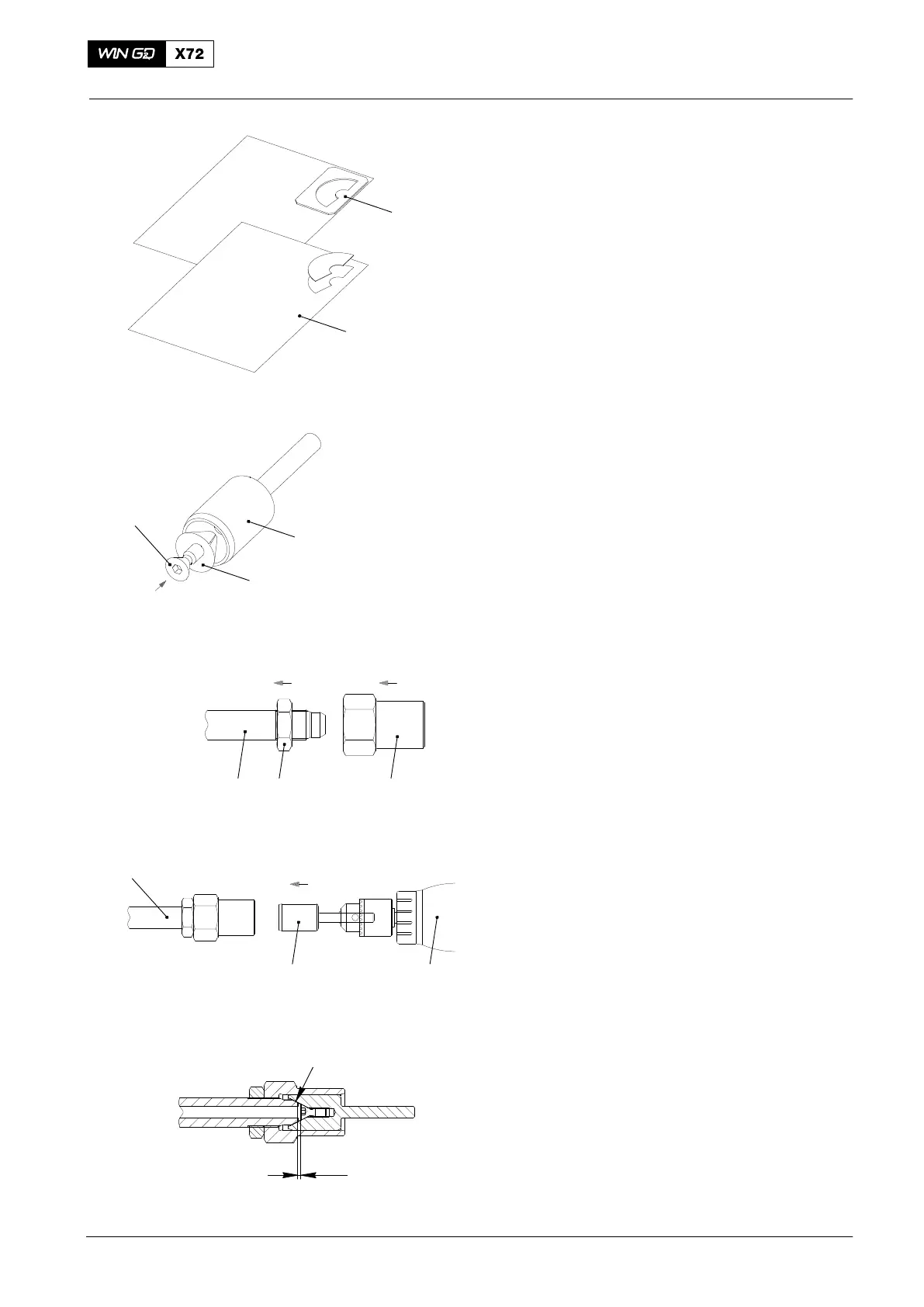

1) Put the template 94870H on the back

of the emery cloth, see Fig. 11.

2) Use the applicable grade of the emery

cloth related to the quantity of metal

you want to remove.

3) Use a pencil or a ball pen to make the

the inner shape.

4) Cut out accurately the shape.

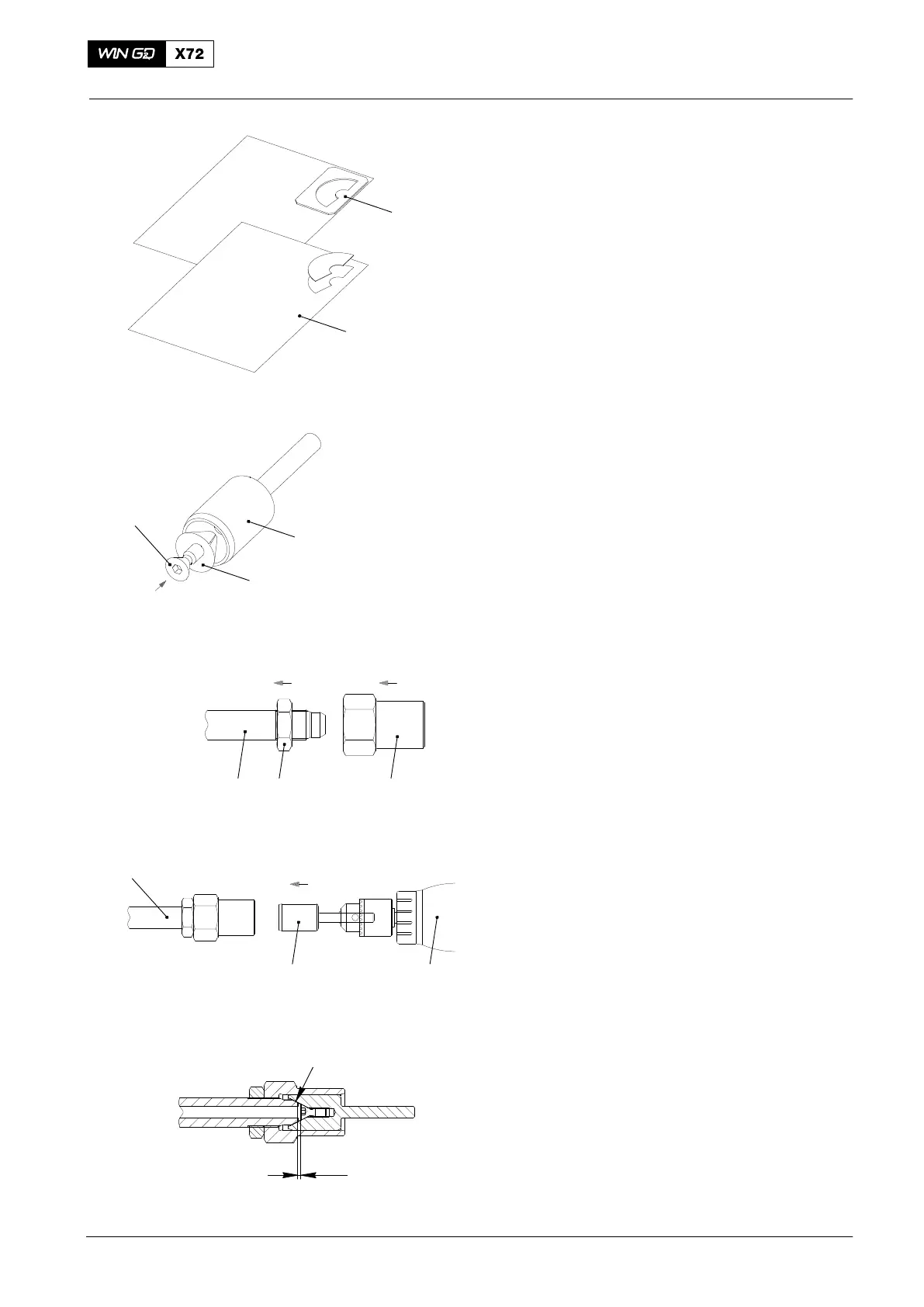

5) Put the cut shape into the cone of the

grinding tool 94870F as shown.

6) Tighten the countersunk screw (1).

7) Remove the pipe claw.

8) Put the HP fuel pipe in position in a

vice.

9) Attach the nut (94870G) on to the

thread of the HP fuel pipe (2).

10) Attach the sleeve (94870E) to the

nut (94870G).

11) Attach the grinding tool (94870F) to the

hand drill.

12) Move the grinding tool (94870F) into

the sleeve (94870E) until the grinding

tool lightly touches the HP fuel pipe (2).

13) Adjust the hand drill speed to a

maximum of 1500 rpm.

14) Operate the hand drill for between

3 seconds to 5 seconds.

15) Remove the grinding tool (94870F)

from the sleeve (94870E).

16) Use a low-pressure air supply to clean

the HP fuel pipe.

17) Do a check of the sealing surface. V if

necessary, use a new piece of emery

cloth and do step 3) to step 16) again.

Note: If the notches are large, you must

decrease the length of the HP fuel

pipe. Make sure that there is a

distance of 0.5 mm between the

countersunk screw (1) and the end

face of the HP fuel pipe.

18) Remove the nut (94870G) and sleeve

(94870E).

2015

HP Fuel Pipe: Removal, Grind the Sealing Faces and Installation

016.738/08

94870H

Emery Cloth

94870F

TIGHTENED

CONDITION

Fig. 11

016.739/08

2 94870G 94870E

1. 2.

016.739/08

Hand Drill94870F

Grained Face

1

2

016.739/08

min.0.5 mm

SF

Loading...

Loading...