Image-Quality Problems

Phaser® 6120 Color Laser Printer Service Manual

4-23

Image-Quality Problems

Image-quality defects can be attributed to printer components, consumable, media, internal

software, external software applications, and environmental conditions. To successfully

troubleshoot image-quality problems, as many variables as possible must be eliminated.

The following guidelines should be used before troubleshooting an image-quality problem:

■ Use an unopened ream of approved media for evaluating image-quality problems

Note: See the approved media list, Media Specifications on page 1-5, for media that has

been tested and approved for use with the Change to local value.

■ When analyzing a image-quality defect, first determine if the defect is repeating or

random. Repeating defects can often be associated with a particular component.

■ Inspect the surfaces of all rollers in the paper path for obvious defects.

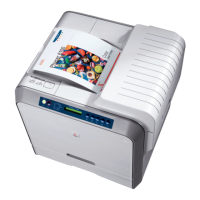

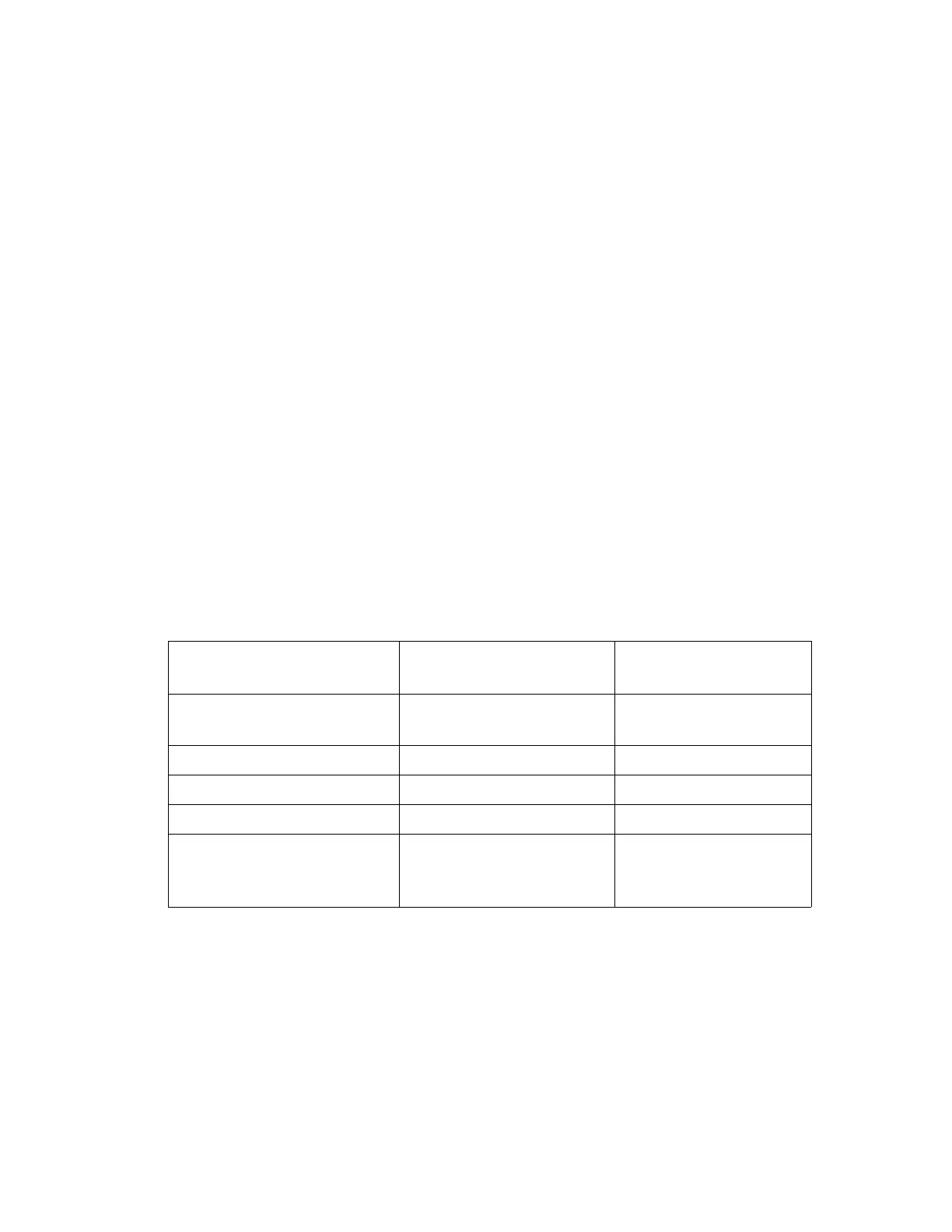

Repeating Defects

Match the distance of the repeating spot or defect in your print and compare it to the

corresponding table below in order to identify the part responsible for the defect.

For example, your prints have a visible spot on the page. This spot repeats (down the page)

every 94.4mm. The chart identifies the Imaging Unit as the most likely cause of the defect.

Consumable, Routine

Maintenance or Service Item Component

Distance on Page Between

Defect

Toner Cartridge Developer Roller

Toner Supply Roller

34 mm

25 mm

Transfer Belt Belt 379 mm

Imaging Unit PC Drum 94.4 mm

Transfer Roller Roller 50.4 mm

Fuser Heat Roller

Backup Roller

Cleaning Roller

108 mm

115 mm

52 mm

Loading...

Loading...