3 - 61

Application of Assembly

Needle threading mechanism

Application

Application

Type B

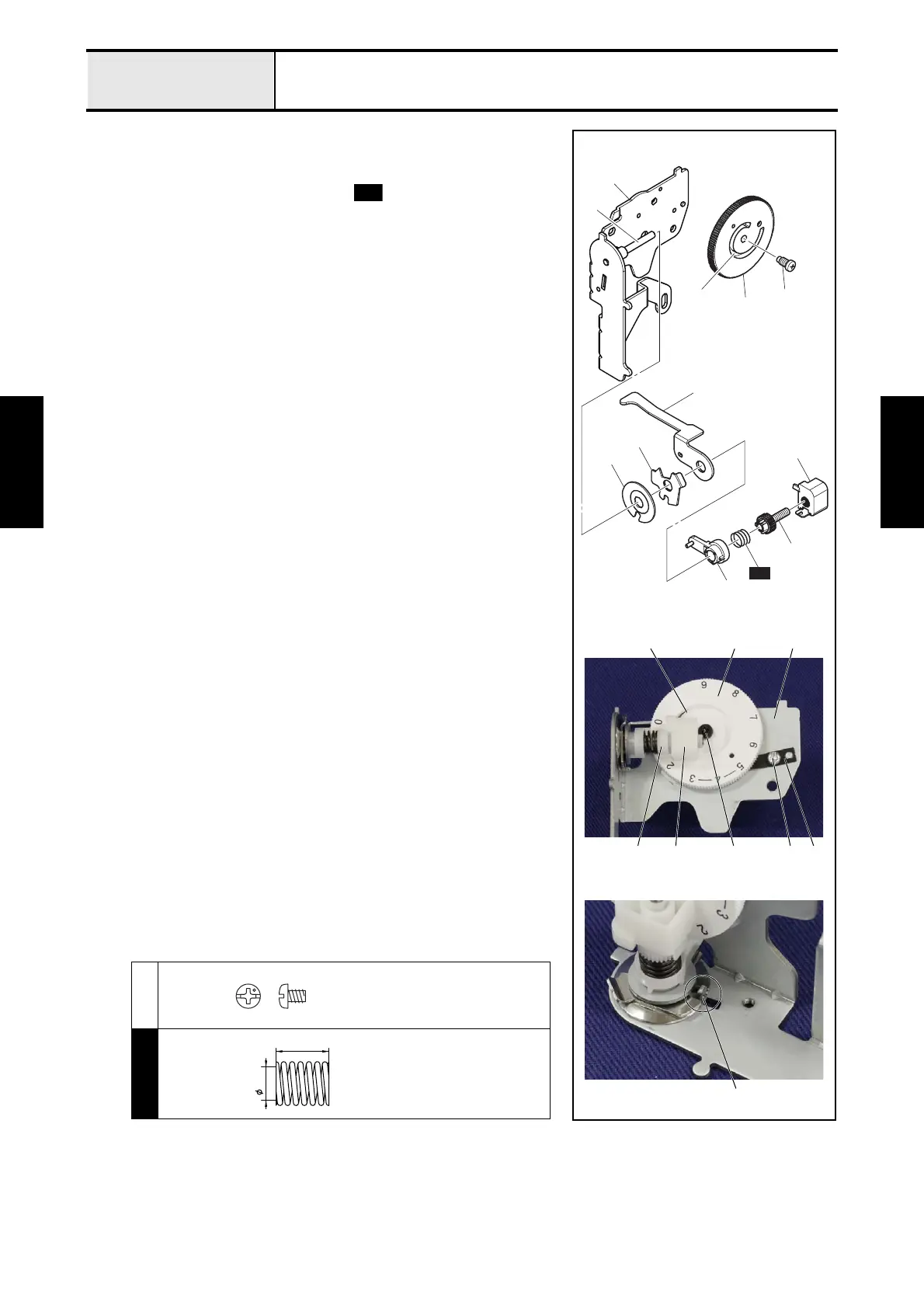

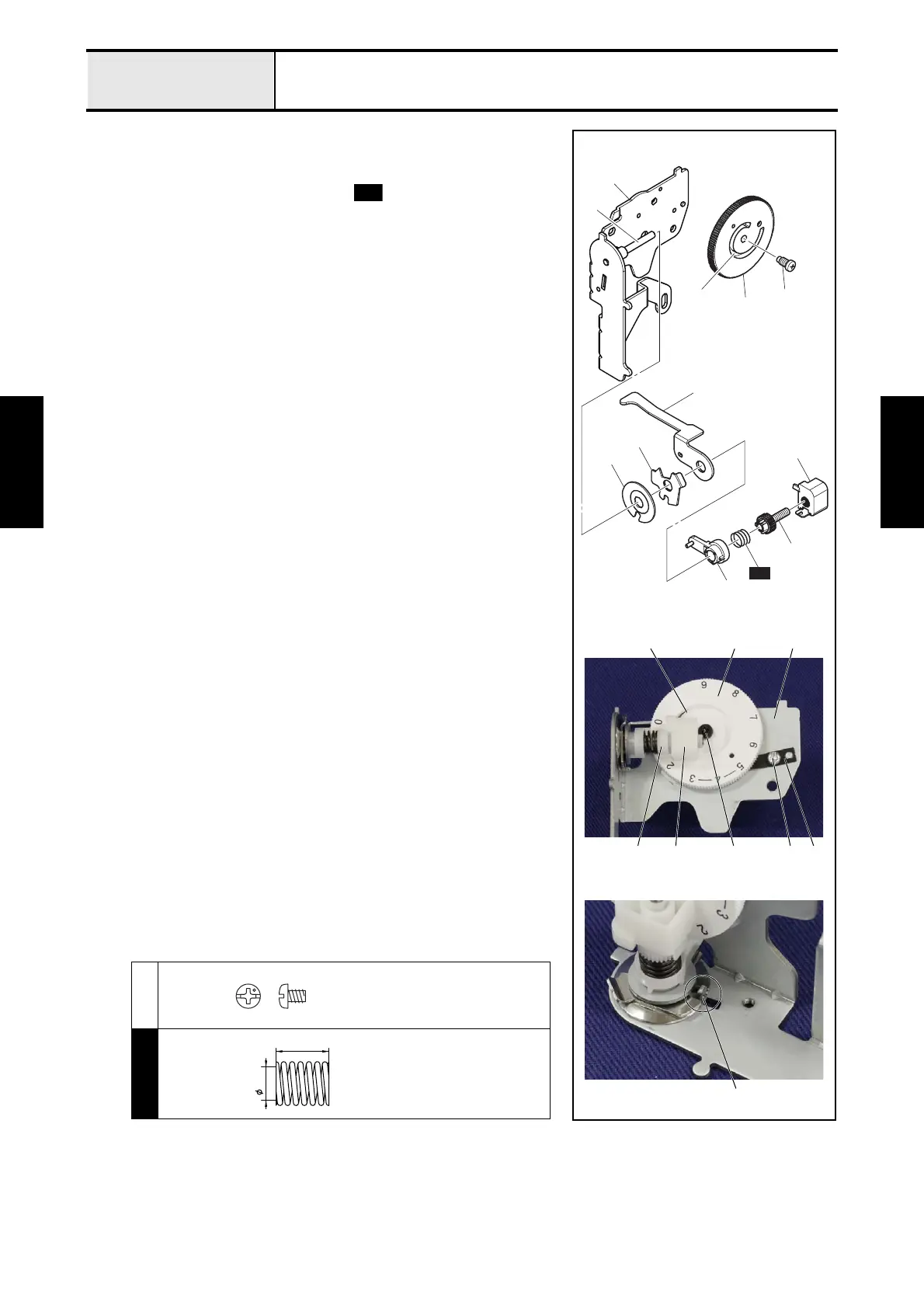

1. Set the thread tension adjusting screw 1 to the thread tension nut 2.

2. Insert the tension disc A 3, the tension plate 4, the tension release plate

5, the spring holder 6 and the spring in this order into the shaft 7

of the thread tension holder assy 8.

*Key point

• Check that align the notch part 9 of the tension disc A 3 and

the tension plate 4 with the protrusion of the thread tension

holder assy 8.

3. Engage the groove part 0 of the thread tension dial A with the protrusion

of the thread tension nut 2, and insert the thread tension adjusting screw

1 into the shaft 7 of the thread tension holder assy 8, and then set the

thread tension dial A to the thread tension holder assy 8 with the tension

dial shaft B.

*Key point

• Set the tension dial shaft B to the thread tension dial A in the

state that the (9) of the thread tension dial A is the topmost

position.

4. Set the notch spring C to the thread tension holder assy 8 with the screw

1.

*Key point

• Attach the end of the notch spring C to the lower side of the

thread tension dial A.

• Check that engage the boss part of the thread tension holder

assy 8 with the positioning hole of the notch spring C.

<In case of Type A, refer to previous page.>

1

S07

B2 C11

A 8

S07

B

A

5

8

7

0

4

6

1

2

3

9

0

S07

Screw, Pan

M3X4

7.6

12

SPRING

X55842***

Loading...

Loading...