Inspection and

Adjustment

Inspection and

Adjustment

4 - 20

Adjustment Needle bar rising

<From previous page>

10. Match up the right edge of the needle with the outer rotary hook point by turning the outer rotary hook assy

counterclockwise by hand.

*Key point

• When the right edge of the needle matches up with the outer rotary hook point, the large side of the

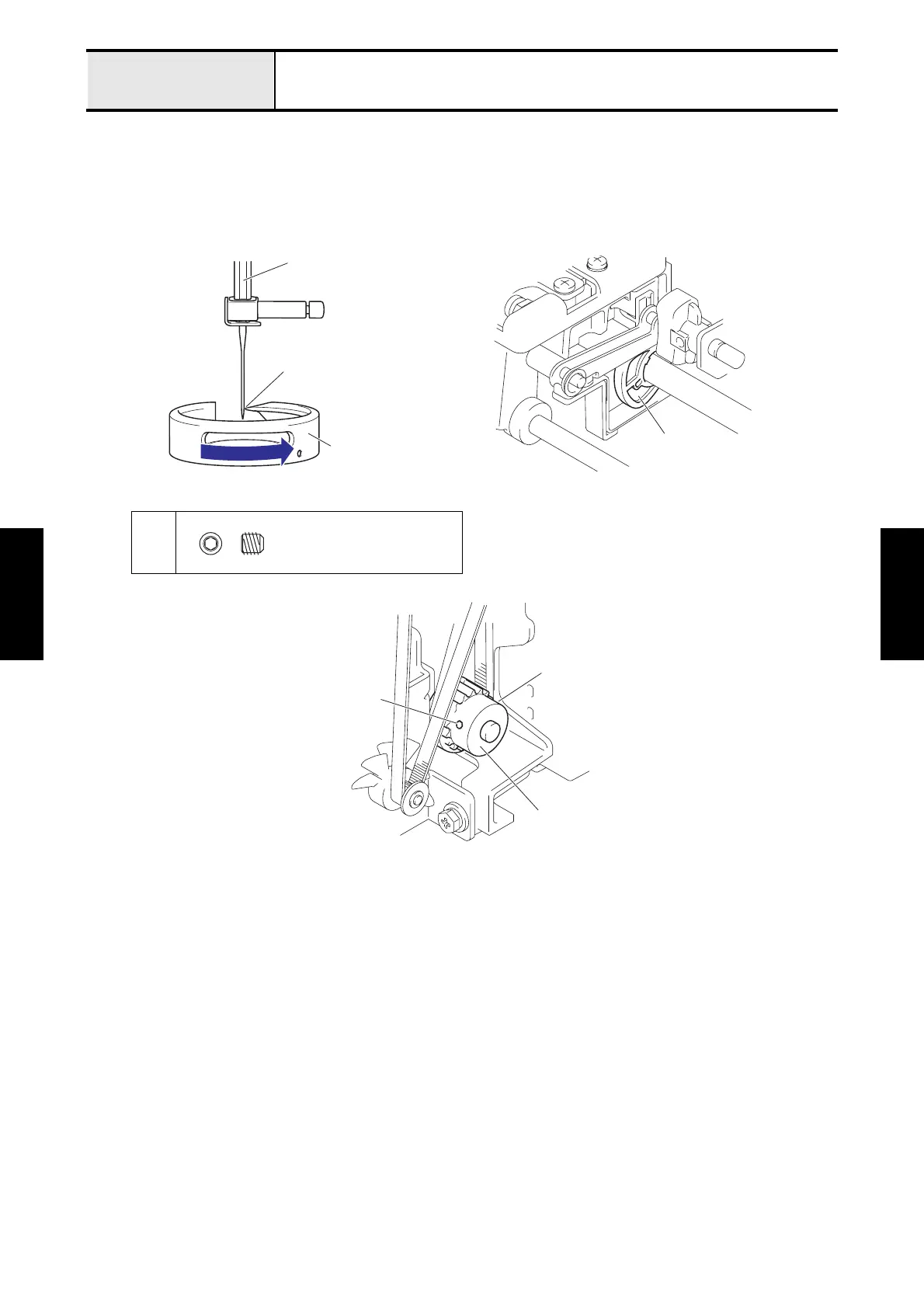

eccentric amount of the feed cam of the lower shaft should be facing directly frontward.

11. Tighten the screws 1 and 2 of the timing pulley D to secure the timing pulley D to the lower shaft.

[Confirmation]

When the needle is lowered to the lowest point by turning the pulley by hand, check that the feed dog is lowered.

1

2

Needle bar

Right edge of needle

and tip coincide

Outer rotary hook assy

Feed cam

Set Screw, Socket (CP)

M5X5

Timing pulley D

1

2

with hex wrench 2.5 mm

with hex wrench 2.5 mm

Loading...

Loading...