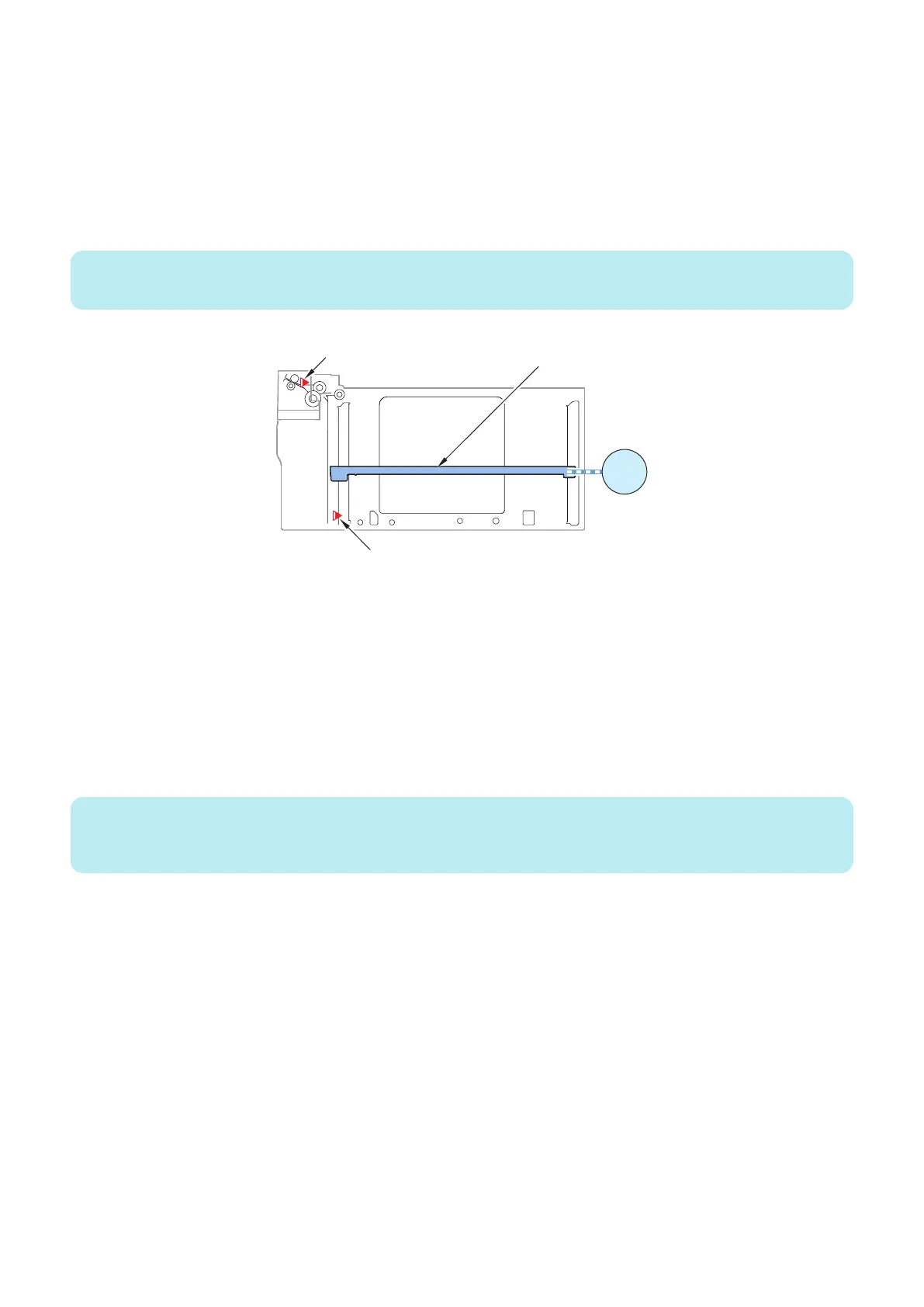

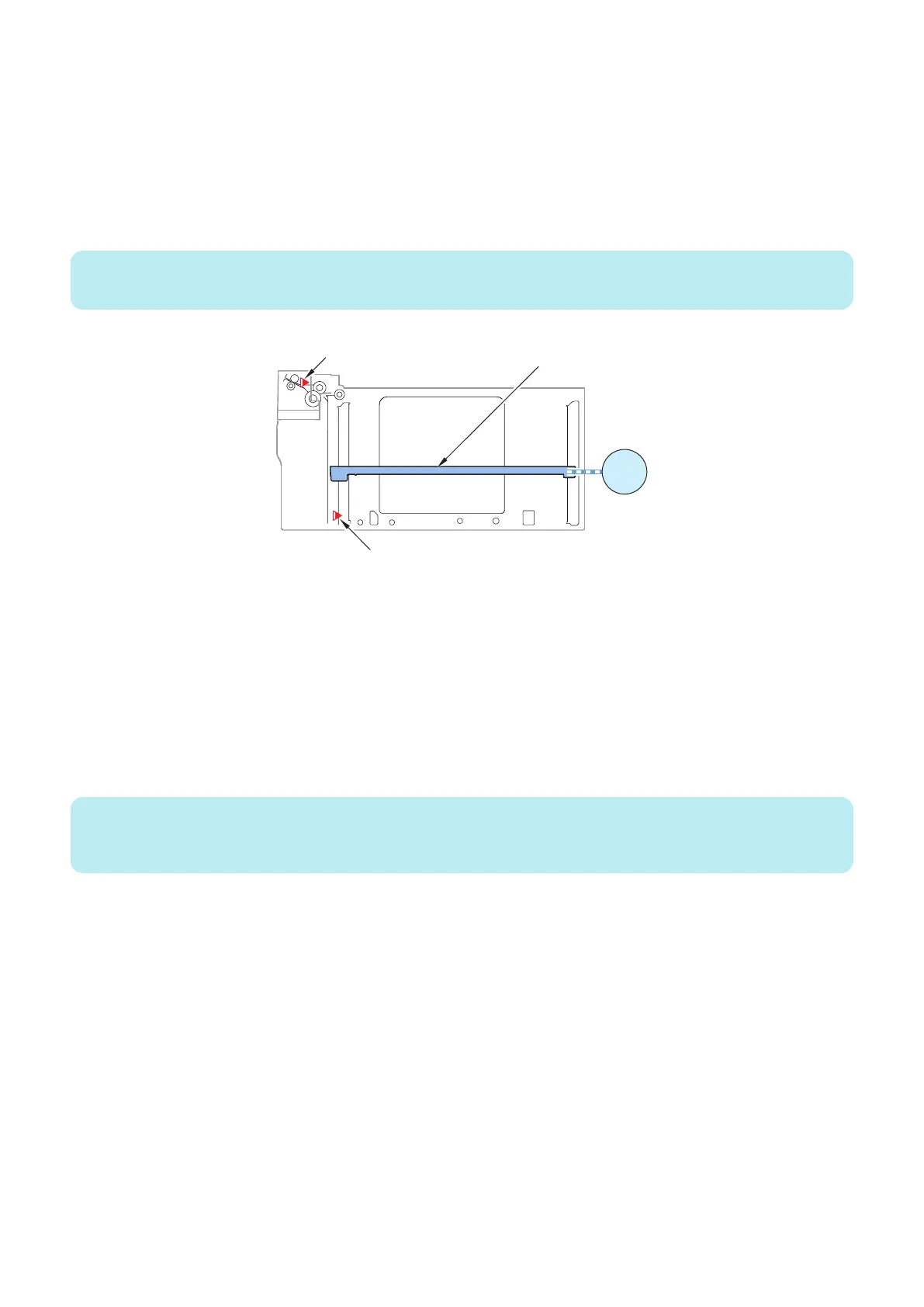

■ Remaining Paper Level Detection Control

The remaining paper level is detected by counting Deck Lifter Motor (M101/ M201/M301) pulses based on which the distance of

lifter travel from the Lifter Lower Limit Sensor (S111/S211/S311) to the Paper Surface Sensor (S106/S206/S306) is calculated

to indicate the paper level.

The pulse count is reset when the Relay Paper Sensor (S104/S204/S304) changes from ON to OFF during paper feed. This is

to correct detection error caused by wire elongation.

When paper runs out in the current pickup inlet, the auto-cassette change function automatically switches the pickup inlet to one

where the same-size paper is set. The switch timing depends on the host machine.

NOTE:

Remaining paper level detection control is performed in the same manner for all decks.

Paper Surface Sensor

(S106/ S206/ S306)

M101

M201

M301

Lifter Lower Limit Sensor

(S111/ S211/ S311)

Lifter

■ Switching between Paper Sizes

The paper size is detected by Deck Size Detection PCB (PCB101/PCB201/PCB301), Paper Length Detection Sensor 1 (S112/

S213/S313), Paper Length Detection Sensor 2 (S113/S214/S314) automatically.

But set paper size from a user mode so that there is the paper size that distinction is not possible.

Example:

1. In the user mode of the host machine, select [Setting/Registration] > [Preferences] > [Paper Setting] > [A5R/STMTR Paper

Selection].

2. Select the paper size of the deck. (Select the A5R or STMTR, and then press OK key).

3. Match a deck with paper size (A5R or STMTR).

NOTE:

• The paper size can be switched in the same manner for all decks.

• Perform the paper size setting of B5 and EXEC equally.

2. Technology

34

Loading...

Loading...