ComNav Commander P2 & P2VS Installation & Operation Installation

Document PN 29010074 V4.1 - 61 -

Each pin receptacle mates with a matching plug; the wires from external equipment &

devices (battery, drive system, compasses, etc.) are inserted into those plugs. The plugs

allow quick installation & removal of system wiring, yet are fully secure, once the various

cables are strain-relieved.

The SPU is shipped with all the plugs normally required, pre-installed on the matching

receptacles (except the Control Head’s plug, which is supplied with it).

The plugs are “Euro style”; they have an internal U-shaped rising-cage wire clamp, driven by

a slot-head screw. To attach a wire, the clamp’s screw must be turned counter-clockwise

several turns (using the small slotted screwdriver mentioned on page 46 –

Special Tools

),

which drives the clamp downwards to open it up; then the wire can be fully inserted into that

clamp. The screw must then be turned clockwise until the wire is tightly held in the clamp.

Wire Sizes

It is important to use the correct size wires in each connector, in both the mechanical &

electrical sense!

Mechanically, due to the amount of vibration & impact shocks that can occur on a boat (from

propeller & engine vibration, hitting waves, etc.), the stripped end of wires must be securely

clamped in the plugs; using a too-small or too-large wire can cause poor clamping.

Electrically, due to the relatively high current requirements of an autopilot compared to many

other types of electronic equipment, it is vital to use the largest possible size of wire to

connect the various components. Undersized wiring will result in power losses which can

affect overall efficiency and performance.

At the same time, due to the corrosive affects of the marine environment on bare wire,

stripping too much or too little insulation from the ends of wires is poor practice. All the

connectors used on the SPU are marine grade, and use corrosion-resistant materials.

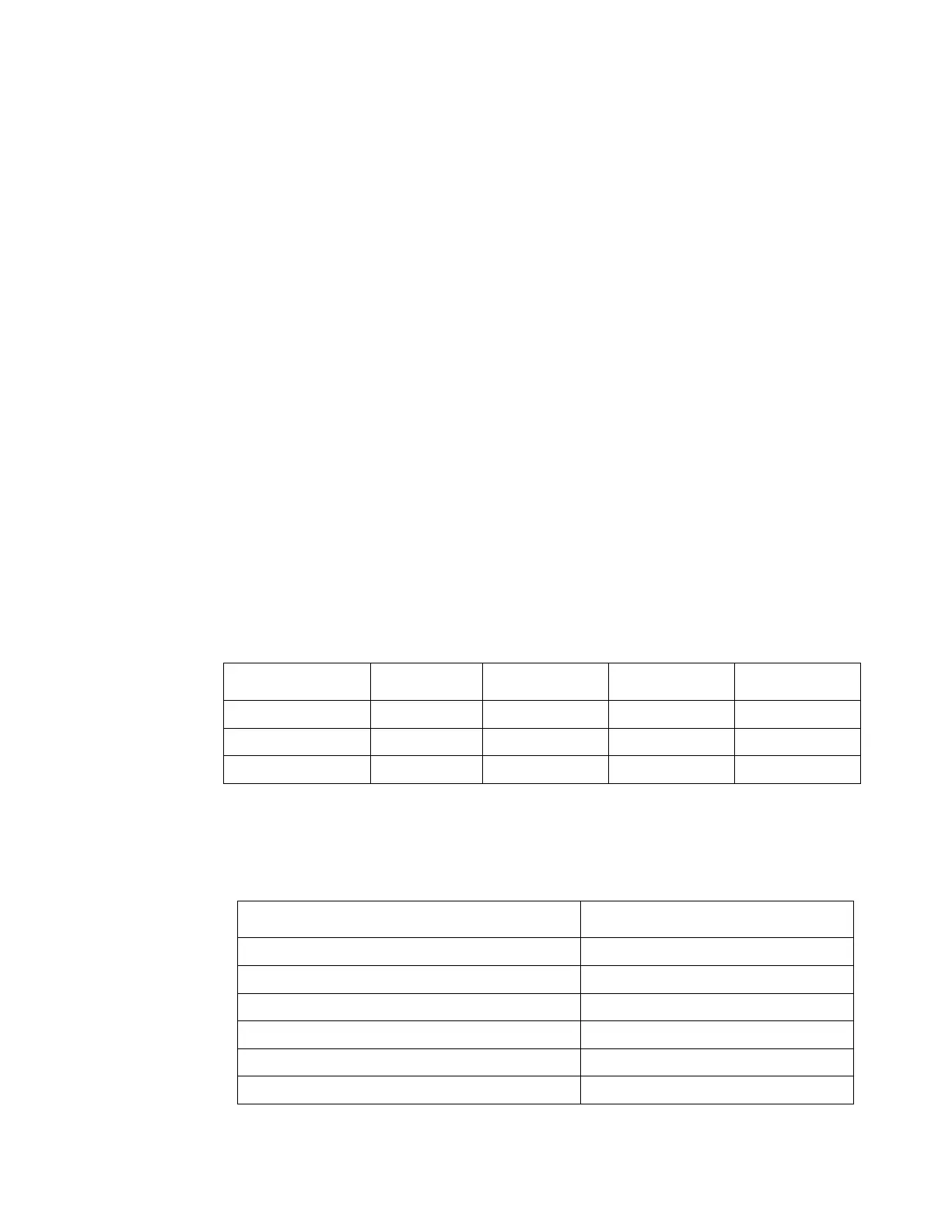

The acceptable wire size range, DC current rating, stripped wire depth and pin spacing for all

the SPU’s connectors are as follows:

Connector Name Wire Gauge Rated Current Wire Depth Pin Spacing

J1, J2 12 – 22 AWG 12 A 6 mm 7.62 mm

J3, J4 12 – 22 AWG 12 A 6 mm 5.08 mm

J5 – J13 14 – 22 AWG 8 A 6.5 mm 3.81 mm

Table 1 – SPU Connector Ratings

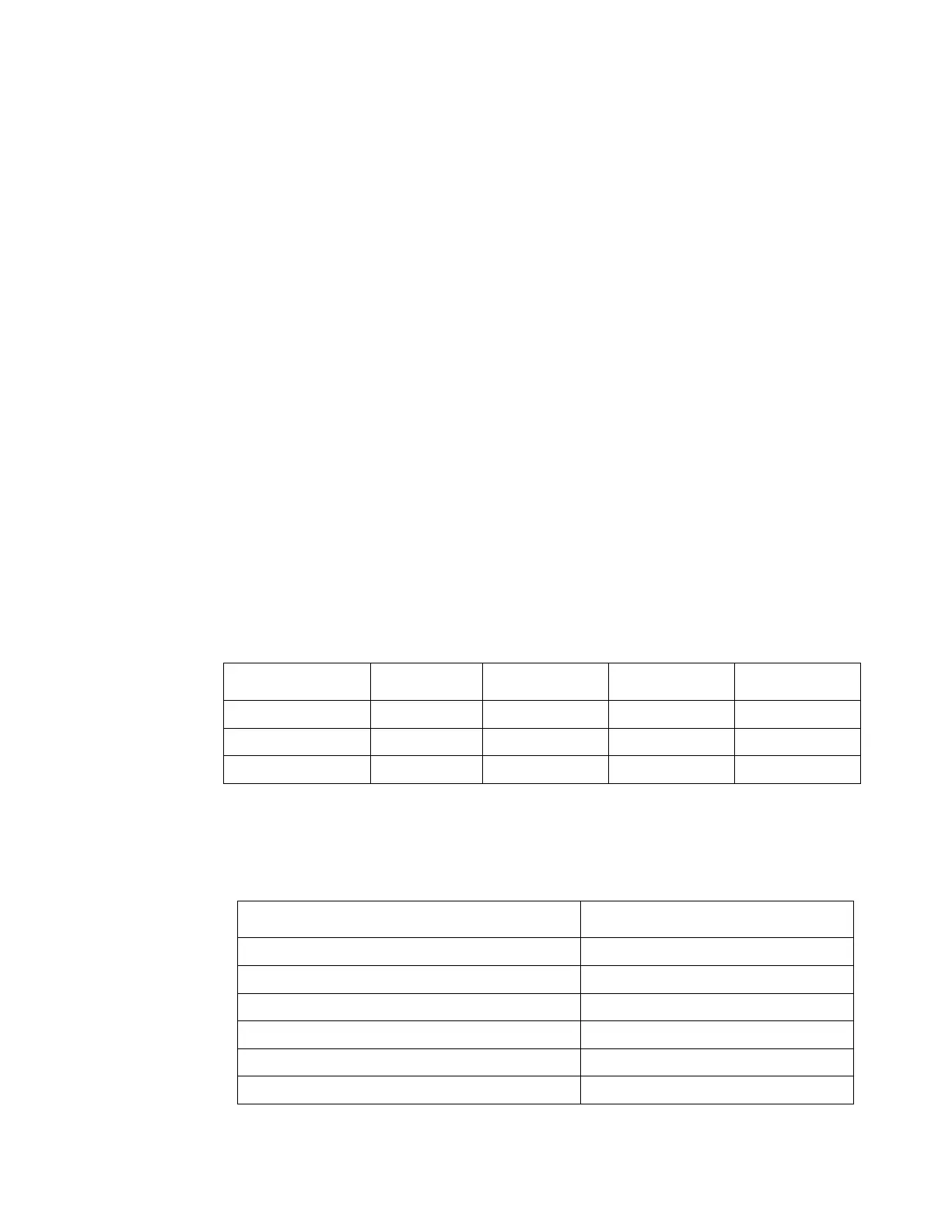

Below are the recommended minimum gauges for the connections to the various elements of

the system. All cables should use stranded wire, and have marine-grade insulation; only the

ones so indicated must be shielded. If in doubt, contact your ComNav Dealer for help.

Function / Use Wire Gauge

SPU Power Supply 2 x 12 AWG

12/24 VDC Solenoid Valve Steering System 3 x 18 AWG

Reversing Motor Steering System 2 x 14 AWG

Rudder Follower Unit 3 x 18 AWG (shielded)

GPS, Chartplotter, Navigation Computer 2 x 22 AWG (shielded)

Rudder Angle Indicator 2 x 22 AWG

Table 2 – Recommended Minimum Wire Gauges

Loading...

Loading...