249 of 282

M-SV-001-EN Rev. G

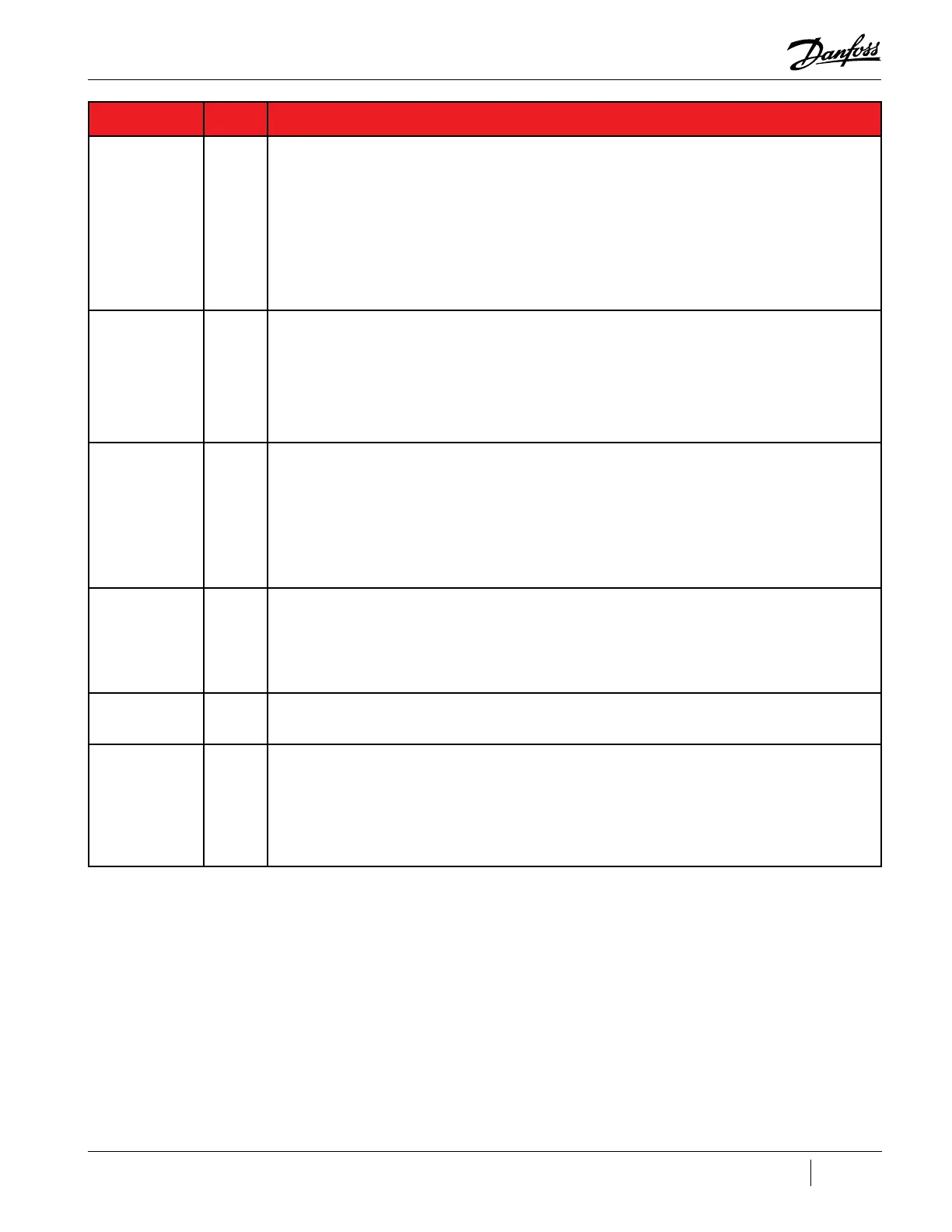

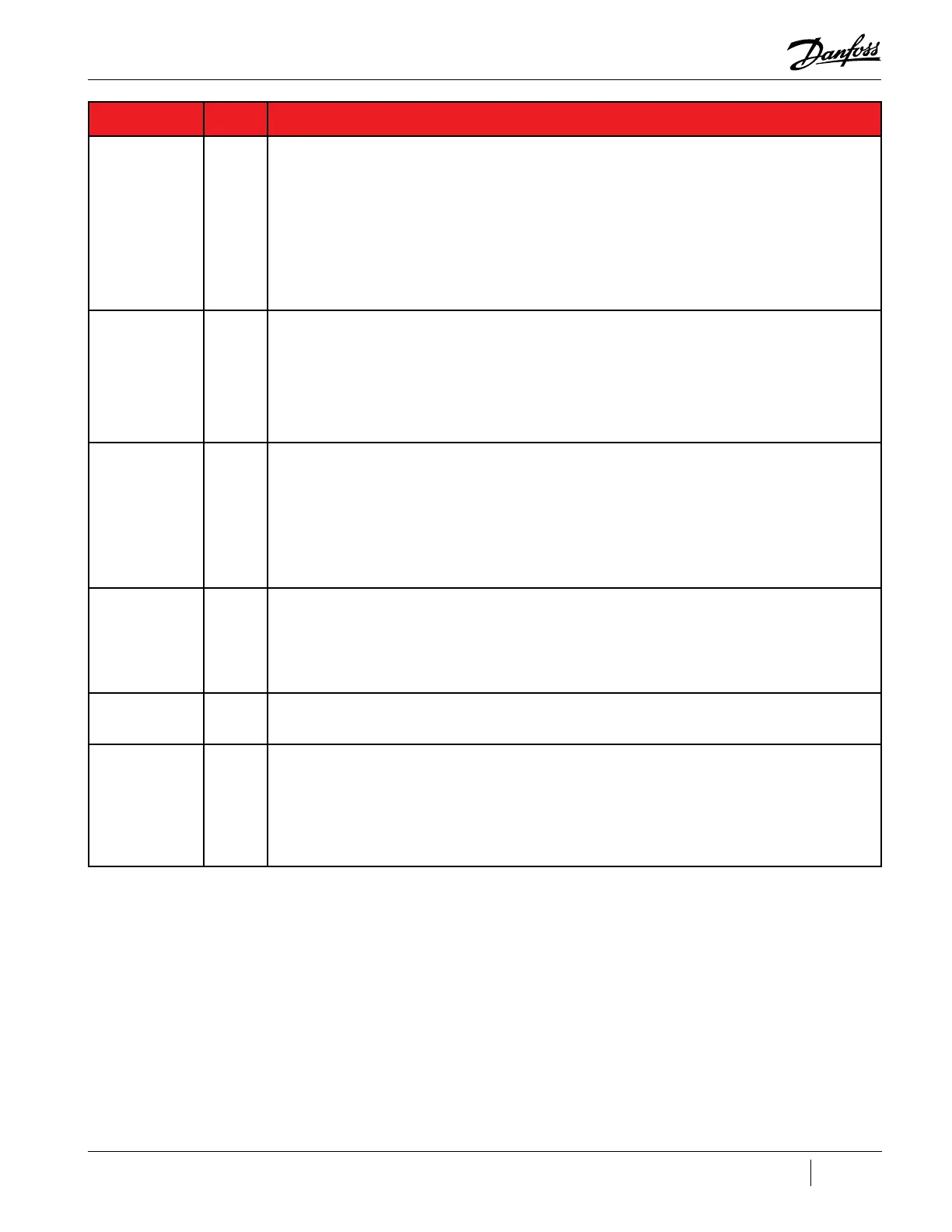

Motor Fault

Descritpion

Trigger

Method

Troubleshooting

DC Bus Under/Over

Voltage Fault

DFT • At 0 RPM: If the measured DC Bus voltage is lower than Soft Start charge voltage, a DC bus voltage fault is

recorded. All 3-phase voltage information displayed in the SMT is calculated from DC bus voltage, as measured by

the Inverter.

• Typically, this fault is recorded when power to the compressor is removed.

• Measure the incoming main AC voltage.

• Compare the measured voltages to the displayed readings in the Compressor Monitor Tool and Fault and Event

Log details to determine conditions related to the fault.

• Measure the DC bus voltage using the DC Bus Test Harness. Refer to "1.10.1 General Verification and Installation of

the DC Bus Test Harness" on page 22.

• Verify the Soft Start. Refer to "4.15.2 Soft Start Verification" on page 109.

• Verify the SCRs. Refer to "4.19.2 SCR Verification" on page 135.

• Verify the connections to the Inverter. Refer to "4.23.2.1 Inverter Verification" on page 165.

24VDC Under/Over

Voltage Fault

RFT • Suggests the measured 24VDC supply voltage is out of range.

• Measure the 24VDC test points at the Backplane. Refer to "4.26.2.2 Backplane Verification" on page 210.

• Compare the measured voltages to the displayed readings in the Compressor Monitor Tool and Fault and Event

Log details to determine conditions related to the fault.

• If the measured voltage is incorrect, verify the DC-DC Converter. Refer to "4.25.2 DC-DC Converter Verification" on

page 201.

• Determine that one of the modules is not draining energy. Refer to "5.5.2 Determining the Cause of an Energy

Drain" on page 257.

• If the fault occurs when the compressor is given the demand to run, the Inverter may be causing the 24VDC fault.

Low Motor Back

EMF

Fault

DFT • The calculated magnetic strength of the shaft has fallen below the minimum limit. This can be a temporary effect

due to high load and elevated temperatures (will recover when cavity temperature cools) or due to a permanent

demagnetization of the shaft.

• If this fault occurs three times within a 30-minute period, a Lock-Out Fault will occur.

• Compare the Back EMF value to the displayed readings in the Compressor Monitor Tool and Fault and Event Log

details to determine conditions related to the fault.

• Permanent damage to Back EMF can be caused by insufficient motor cooling, repeated overheating of cavity,

faulty Inverter, faulty BMCC, repeated Rotor May Be Locked or Single phase Over-Current faults. See Inverter Error.

• Verify the Inverter. Refer to "4.23.2.1 Inverter Verification" on page 165.

• Verify the Stator. Refer to "4.24.4 Motor Verification" on page 192.

Generator Mode

Active

DFT • Indicates, at greater than 0 RPM, the measured actual DC Bus voltage has fallen below the Generator Mode

Enabled Level value. Also, could be electronic “noise” when no actual drop in voltage has occurred.

• Measure the incoming main AC voltage.

• Measure the DC bus voltage using the DC Bus Test Harness.

• Compare the measured voltages to the displayed readings in the Compressor Monitor Tool and Fault and Event Log

details to determine conditions related to the fault.

• Typically, this fault is recorded when power to the compressor is removed while it is running.

EEPROM Checksum

Fault

INS • Indicates there is an error reading the EEPROM in the BMCC.

• Perform a bearing calibration and save to EEPROM, cycle the power.

• If the error is still present, the BMCC must be replaced.

SCR Ripple Voltage

Fault

AFT • Indicates that a voltage imbalance may exist between the incoming AC phases.

• Measure the difference in current and voltage between the phases.

• If there is a current imbalance (more than 5%) between the phases, verify the incoming AC power supply.

• Review the Compressor Monitor Tool for SCR Voltage Ripple readings at the time of the fault.

• Phase imbalance can be caused by a faulty SCR, SCR Gate, Gate control from the Soft Start Board, or a faulty power

capacitor.

• Verify the SCRs. Refer to "4.19.2 SCR Verification" on page 135.

• Verify the Soft Start Board. Refer to "4.15.2 Soft Start Verification" on page 109.

Loading...

Loading...