Chapter 4 -Operational Procedures-

106

AS-410M Auto Slide Preparation System

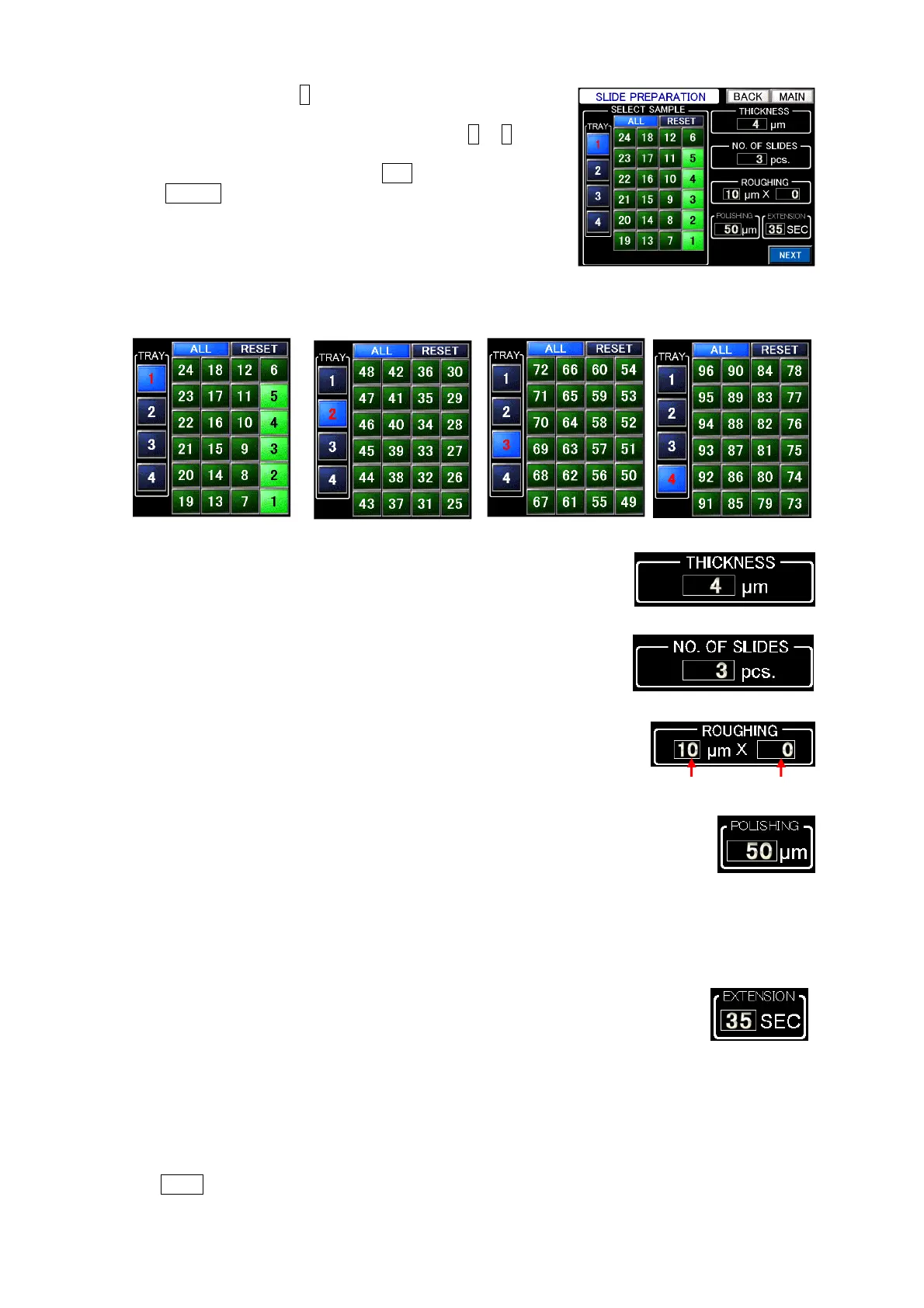

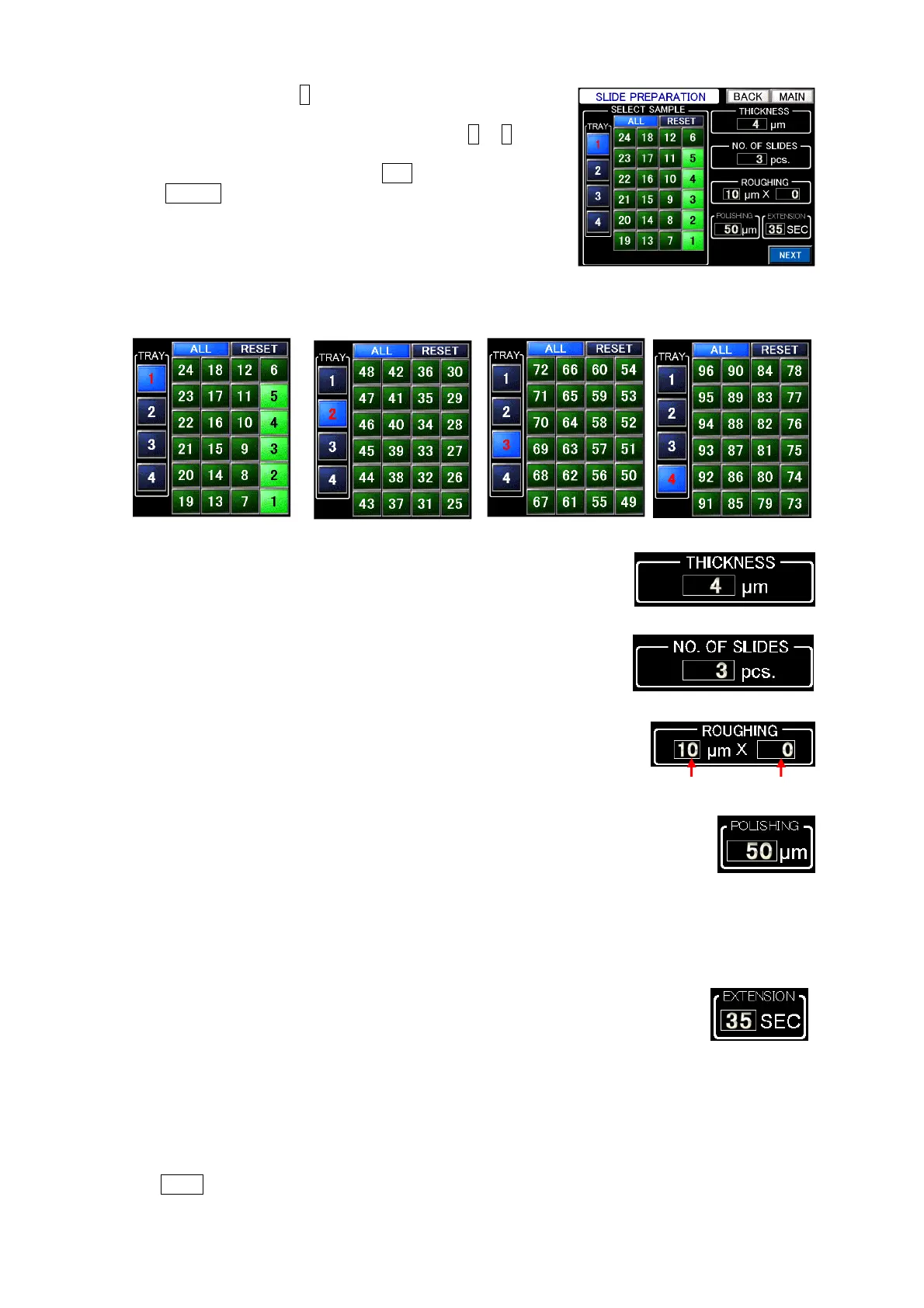

< System with BS-96 >

1. Touch Tray No. button 1 and go to Step 2.

2. Touch the position No. buttons of the samples

to be sliced. Repeat the same for Tray Nos. 2 to 4.

To select all samples in a tray, touch ALL.

Touch RESET to deselect all samples in the tray.

② Specify the section thickness. The thickness is settable

in increments of 1

μ

m, within the range of 3 to 10

μ

m.

③ Specify the number of section slides to be prepared per block.

• Setting range: 1 to 100 slides (System with 100-slide dry chamber)

1 to 400 slides (System with 400-slide dry chamber)

④ Specify the rough-cutting thickness and number of cuts.

• Setting range: Thickness from 3 to 30 [μm]

• Setting range: Number of trimming cuts from 0 to 999 (Set to 0 to skip

rough-cutting.)

⑤ Specify the polishing thickness. The cutting thickness is

the sectioning thickness per trimming operation performed to align the block

surface with a microtome blade. When the cutting thickness setting is updated here, the sectioning

parameter values will also be updated.

・Setting range: 1 to 500 [μm]

⑥ Specify the stretching (extension) time.

・ Setting range: 1 to 99 [Sec]

* As for the extension time, the value set on the “SLICING PARAMETER SETTING” screen will

be loaded by default when the screen opens and when the section thickness setting is updated.

When the stretching time setting is updated here, the sectioning parameter values will also be

updated.

⑦ Touch NEXT.

Slide preparation condition settings screen

in STANDARD mode (Sys. with BS-96)

Tray 1

Tray 2 Tray 3 Tray 4

Thickne

s

s

No. of

cuts

Loading...

Loading...