Chapter 4 -Operational Procedures-

108

AS-410M Auto Slide Preparation System

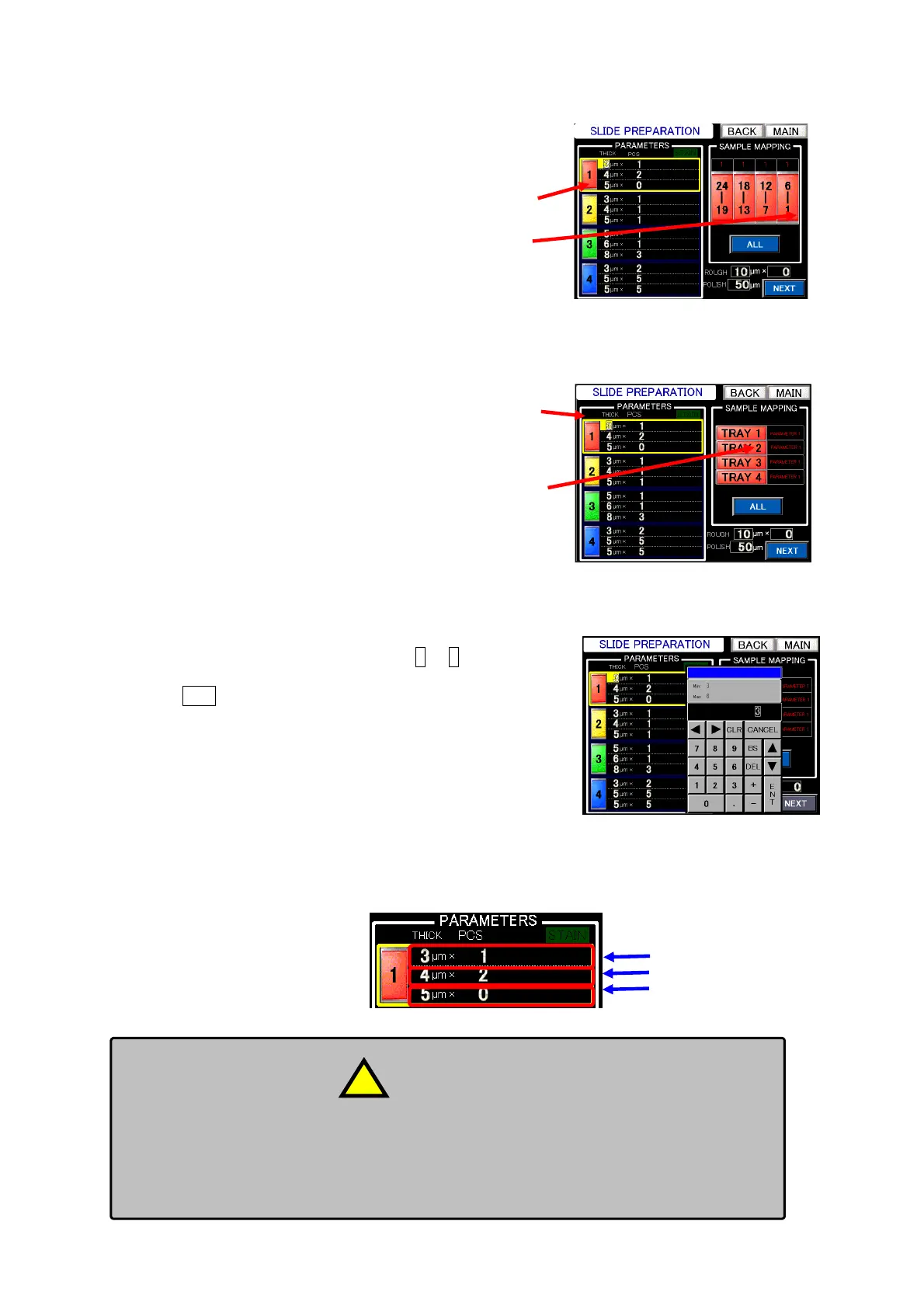

② Apply the sectioning conditions

< System with BS-24 >

1. Touch the numbered button of the parameter to be used.

2. Touch the numbered button of the line to be

used from the tray.

With a 24-block tray, line-by-line parameter setting is

possible.

Line 1 (Sample Nos. 1 to 6)

Line 2 (Sample Nos. 7 to 12)

Line 3 (Sample Nos. 13 to 18)

Line 4 (Sample Nos. 19 to 24)

< System with BS-96 >

1. Touch the numbered button of the parameter to be used.

2. Touch the numbered button of the tray to be used.

With 4 trays/96 blocks, tray-by-tray parameter

setting is possible:

Tray 1 (Sample Nos. 1 to 24)

Tray 2 (Sample Nos. 25 to 48)

Tray 3 (Sample Nos. 49 to 72)

Tray 4 (Sample Nos. 73 to 96)

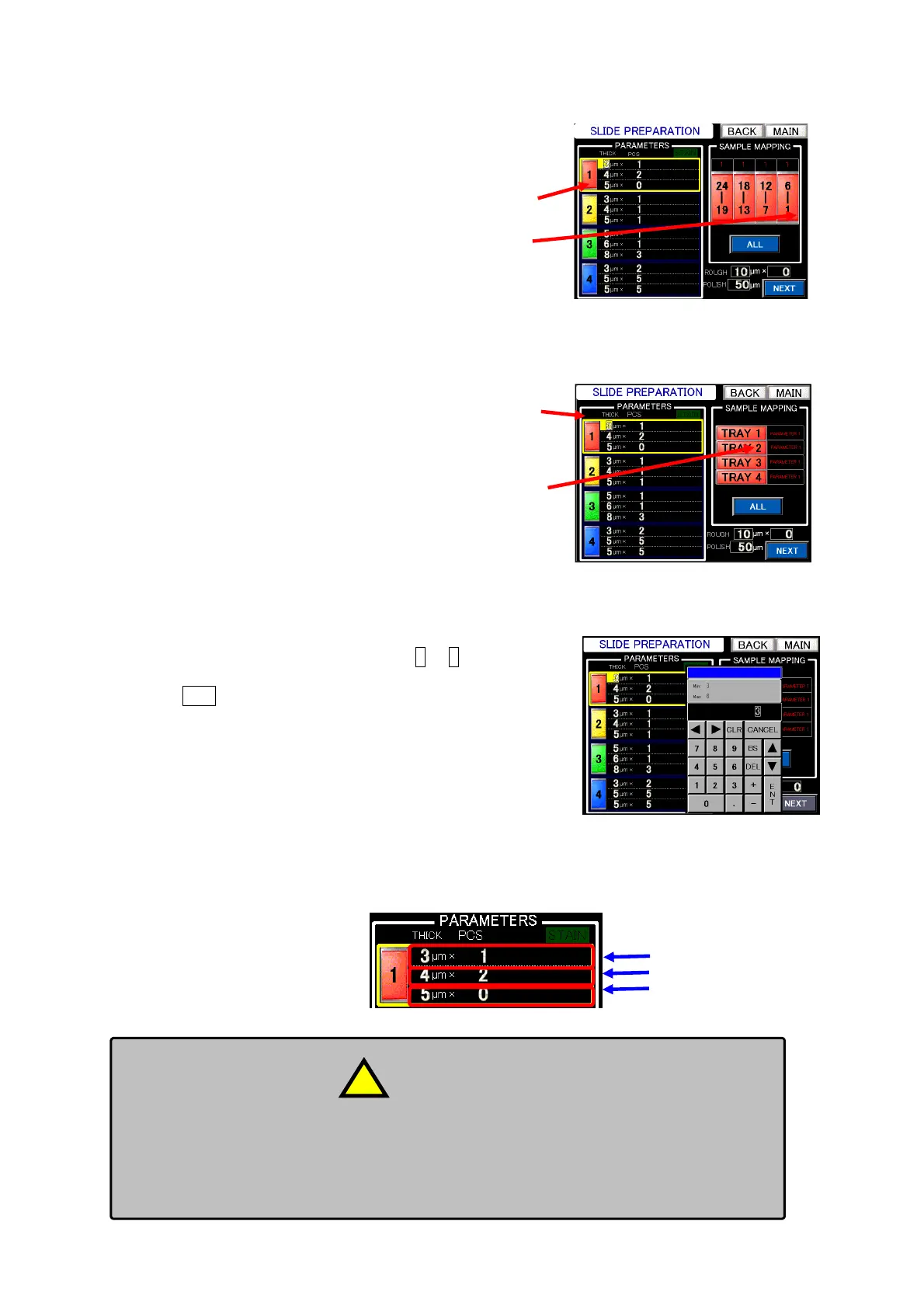

③ Edit the sectioning parameters

Touch and hold any of the numbered buttons 1 to 4 for 2 seconds.

Then, a numerical keypad appears for use for value entry. Each

touch on the ENT key moves the cursor once. Once 3 different

sets of values are set, the numerical keypad will automatically

close.

Up to 3 different sets of values can be set per sectioning condition.

Enter a sectioning thickness and number of slices for each sectioning condition.

When making changes to the section thickness in a single block, be sure to set

thicknesses in order from the thinner to the thicker to prevent uneven slicing.

For example, when cutting 3 μm-, 5 μm-, and 7 μm-sections, set 3 μm as the first

condition (1st.), 5 μm as the second condition (2nd.), and 7 μm as the third

condition (3rd.).

②

Slide preparation condition setting

screen (with Num. keypad)

Slide prep. cond. 1

Slide prep. cond. 2

Slide prep. cond. 3

Slide preparation condition settings

screen in EXPERT mode (Sys. with BS-96)

①

Slide preparation condition settings screen

in EXPERT mode (Sys. with BS-24)

②

! Caution

Loading...

Loading...