Chapter 4 -Operational Procedures-

110

AS-410M Auto Slide Preparation System

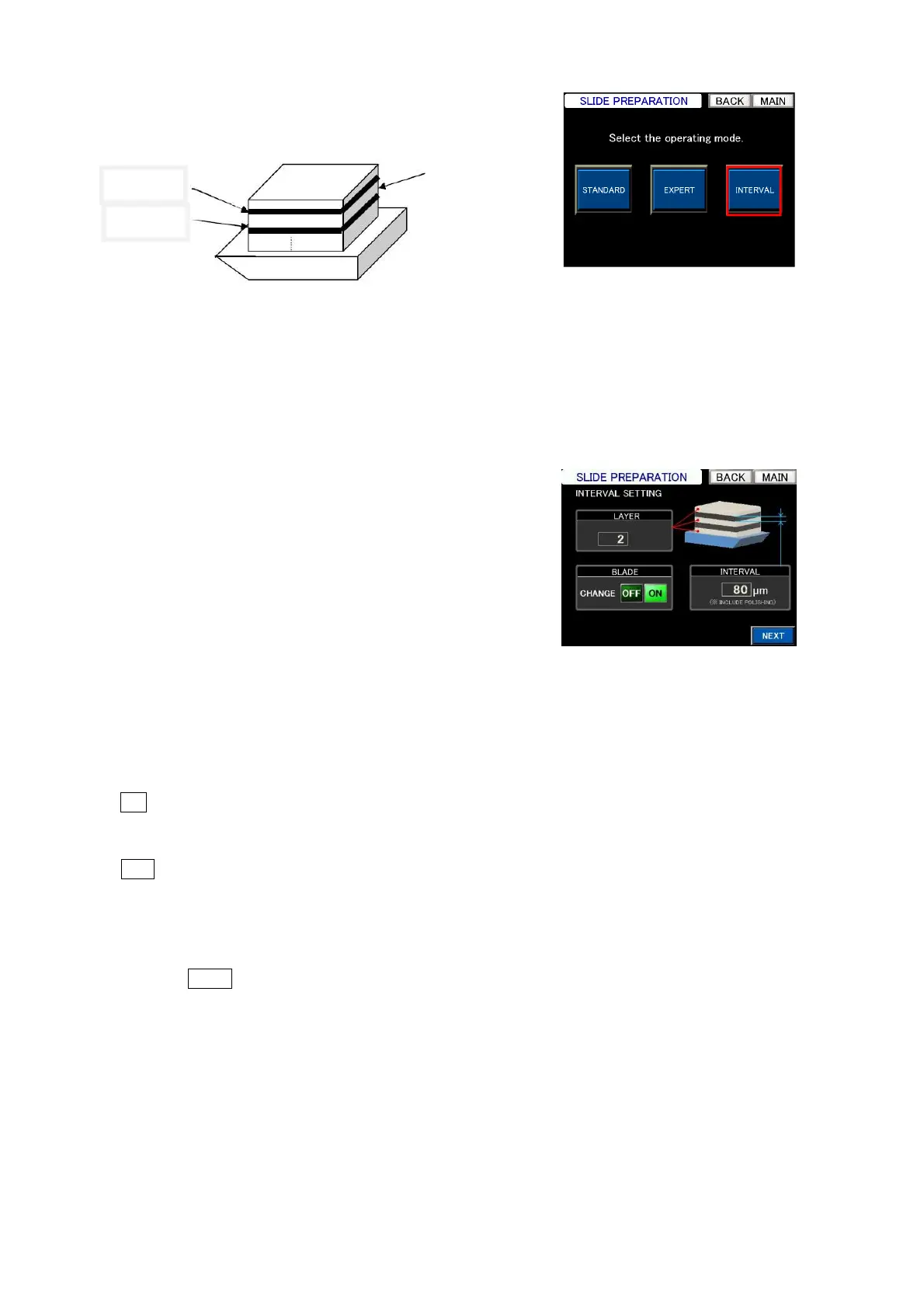

The layer condition setting screen is indicated when selecting the INTERVAL Mode.

The INTERVAL Mode can make slide sections from

designated thickness of multiple layers from a sample block.

Layer 1: After rough cutting and polishing is conducted, a section slide is created. (The rough

cutting and polishing volumes are set in the section slide preparation condition.)

After the interval is cut, the Layer 2 and rest of the section preparation are operated with the

condition set in the screen. The sectioning condition of the interval operation is the same as the

polishing operation.

① Number of layers: Set the number of layers for

slide preparation. The numeric keypad will be indicated

when

the number part is touched.

Setting range: 2 to 100 (System without SS)

2 to 400 (System with SS)

② Interval:

Set the thickness of the layer to be discarded. The

numeric keypad will be indicated when

the number part is touched.

Setting range: 1 to 999 [µm

③ Blade transfer

ON: Slicing of the rough cutting and interval-cutting modes are operated on position A; Slicing

of polishingand sample section preparation modes are operated on position B. *Note:

Polishing is always conducted in each step layer.

OFF: Slicing of the rough cutting and polishing of the first layer are operated at position A;

Slicing of the interval-cutting and sample section preparation modes of the second step

layer on are operated on the same position of the knife (position A).

In either case, the blade change is set in the slide section parameter of each block.

④ Touch the NEXT button to set the position of the block, the numbers, etc. of the slide section

condition. Refer to 4-4-2-1 “Slide preparation condition settings (STANDARD Mode)” for setting

the section condition.

Mode selection screen

Interval Cut Setting screen

Interval

Layer 1

Layer 2

Loading...

Loading...