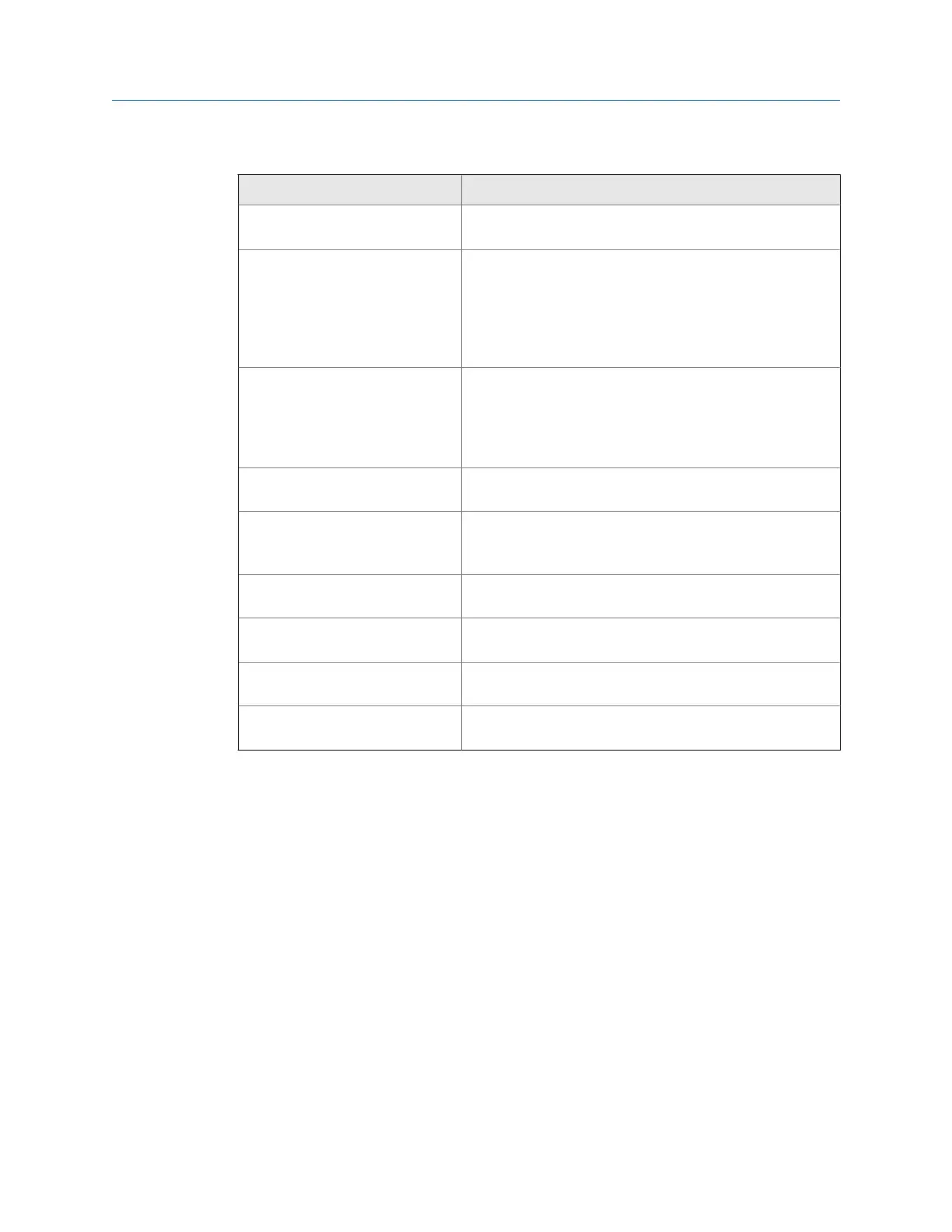

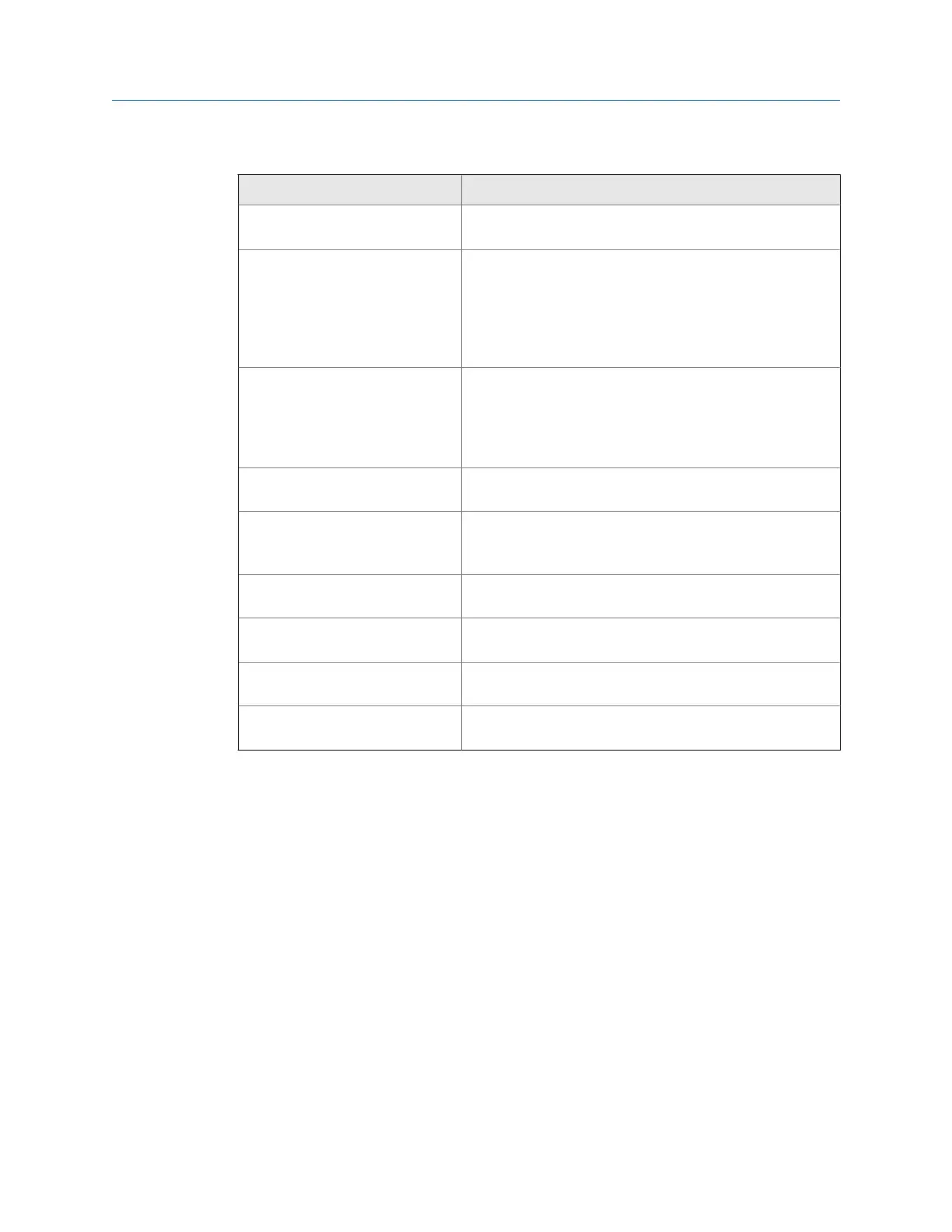

Uses for Analysis Experts (continued)Table 6-1:

Symptom or task Recommended Analyze Expert

You want to confirm if vibration is

bearing-related (non synchronous).

• Synchronous Analysis. See Section 6.8.16.

• High Frequency Analysis. See Section 6.8.3.

You suspect resonance. • Bump Test Equipment Running. See Section 6.8.11.

• Bump Test Equipment Off. See Section 6.8.10.

• Coast Down Peak Hold with no tachometer signal. See

Section 6.8.12.

• Coast Down Peak and Phase with tachometer signal. See

Section 6.8.13.

You suspect an electrical problem. • High Resolution Analysis with 2x turning speed peak marked

with a cursor. See Section 6.8.4.

• High Resolution Analysis with 1x turning speed peak marked

with a cursor. See Section 6.8.4.

• Rotor Bar Test Motor Current. See Section 6.8.14.

You suspect a rolling element

bearing failure.

• Bearing Gear Analysis - PeakVue. See Section 6.8.5.

• High Frequency Analysis. See Section 6.8.3.

You notice equipment speed varies

during data collection and is

smearing the spectrum.

• Order Tracking. See Section 6.8.15.

You want to know the turning

speed.

• Turning Speed Detection. See Section 6.8.7.

• Laser Speed Detection. See Section 6.8.8.

You suspect gear problems. • Bearing Gear Analysis - PeakVue. See Section 6.8.5.

• High Resolution Analysis. See Section 6.8.4.

You want to plot the movement of

the shaft.

• Orbit Plot. See Section 6.8.18.

You want to distinguish between

misalignment and looseness.

• Cross Channel Amplitude/Phase. See Section 6.8.19.

6.8.2 Enable or disable the help text in the Analysis Experts

Each Analysis Expert provides help text to guide you through the measurement. If you

disable the help, measurements automatically begin when you select the Analysis Expert. If

you enable the help, press Enter or Start to collect data.

Procedure

1.

From the Analyze main menu, press ALT > F10 Expert Help.

Each time you press F10 Expert Help, the selected option changes.

2. Press Enter.

Analyze and Advanced Analyze

MHM-97432 Rev 7 125

Loading...

Loading...