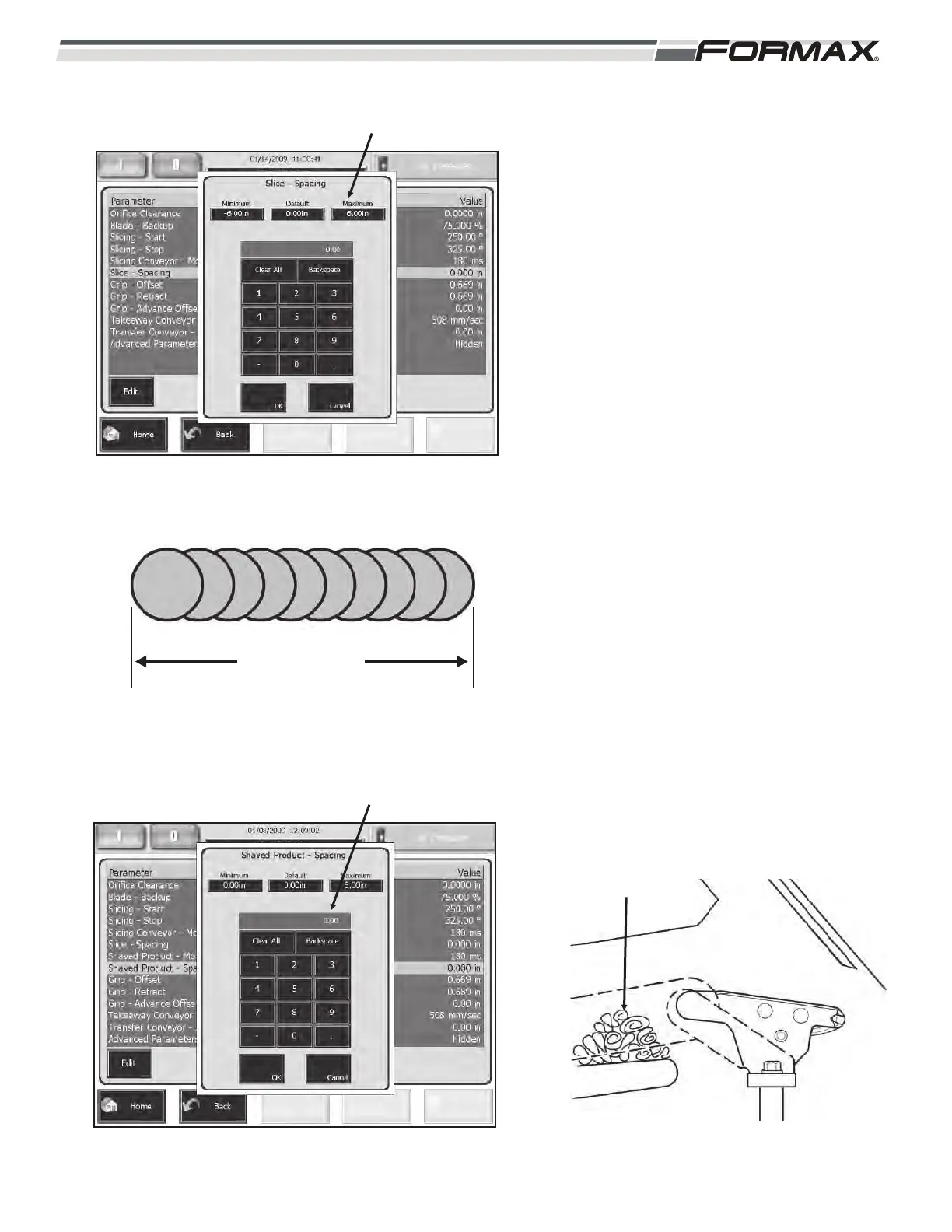

(“Shingle” selected in the “Portion Type”):

If “Shingle” is selected, the “Slice Spacing”

adjustment displays and controls the speed and

travel distance of the Slicing Conveyor while

shingling a draft. The larger the setting, the

greater the slice spacing and the longer the

overall draft length. (Illustration 54 and 55) Set

this parameter high enough for the draft to fill

the packager pocket.

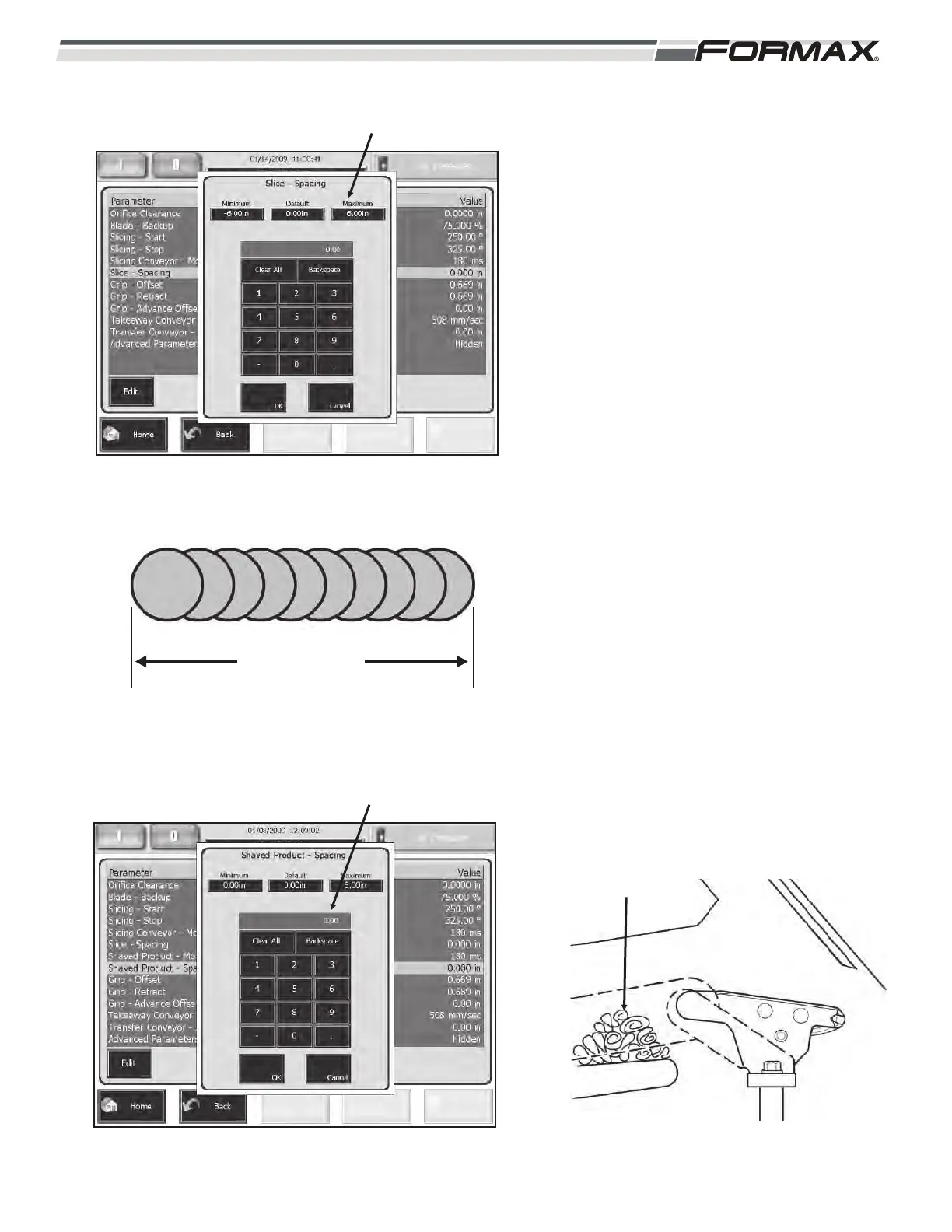

(“Shaved” selected in the “Portion Type”):

If “Shaved” is selected, the “Shaved Product

Spacing” adjustment displays. This adjustment

controls the speed and travel distance of the

Slicing Conveyor while the “shaved” product is

sliced. This adjustment must be set to a long

“slice spacing” distance in order to create a

“bunched” pile of product on the Transfer

Conveyor. (Illustration 56 and 57)

If the setting is too low, the slices will not

roll and “Bunch” into a pile properly.

031914 6-21

ILLUSTRATION 56

“SHAVED PRODUCT SPACING” ADJUSTMENT

ILLUSTRATION 55

DRAFT LENGTH

ILLUSTRATION 54

“SLICE SPACING” ADJUSTMENT

ILLUSTRATION 57

BUNCHED PILE

Loading...

Loading...