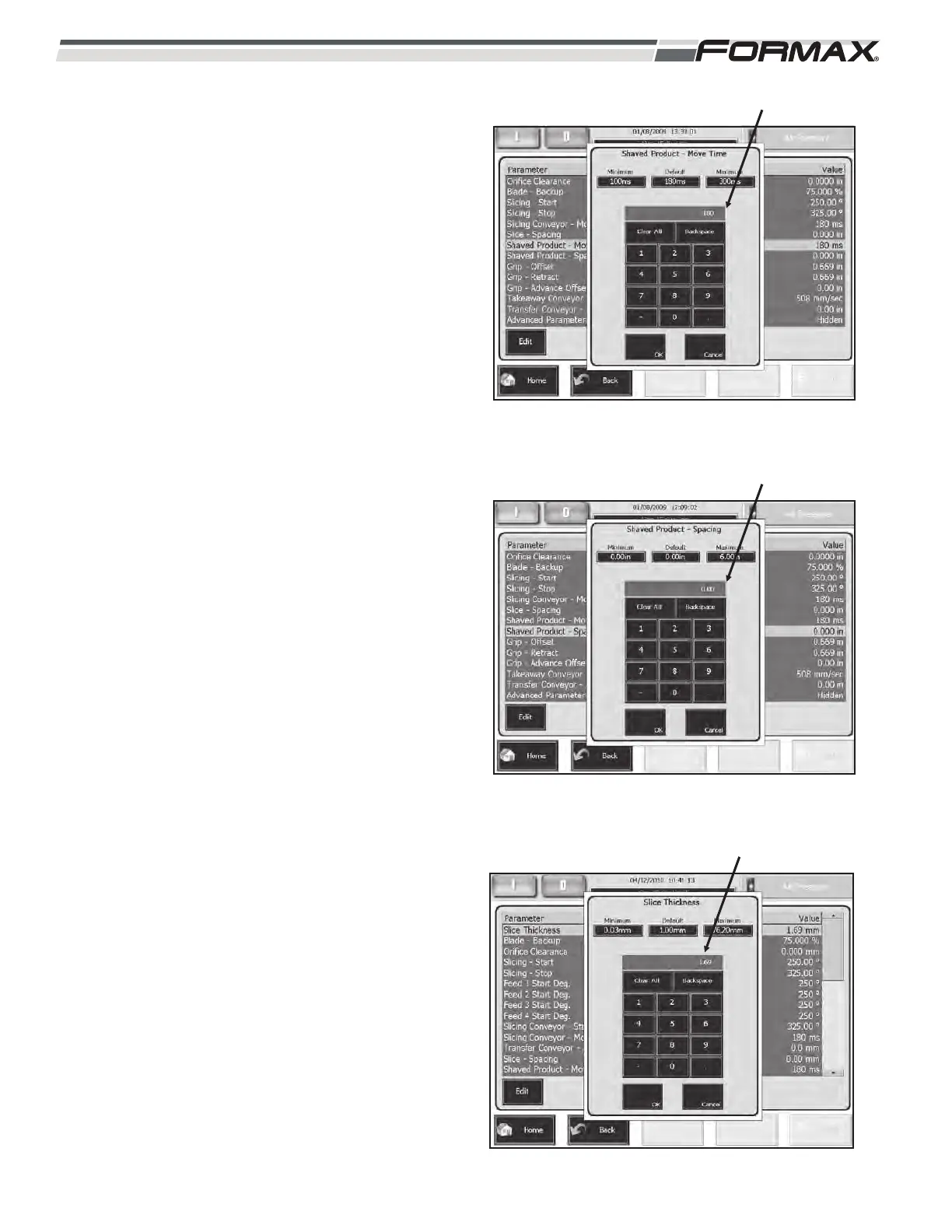

SHAVED PRODUCT MOVE TIME: The “Shaved

Product Move Time” adjustment is only displays

when operating in “Shaved Mode.” (Illustration 58)

The “Shaved Product Move Time” adjustment is

programmed in milliseconds and sets the

acceleration rate of the transfer Conveyor when

transferring “bunched” Shaved product” to the Scale

Conveyors.If the “Shaved Product Move Time” is

set to 300 milliseconds, the Transfer Conveyor will

take 300 milliseconds to go from a stopped position

to full speed. The higher the “Shaved Product Move

Time” setting, the slower the Transfer Conveyor

travels.

Setting the “Shaved Product Move Time” too fast,

will result in rolled over and separated slices from

the “bunched” product.

Setting the “Shaved Product Move Time” too slow,

will lower the Production Output of the Slicer.

SHAVED PRODUCT SPACING: The “Shaved

Product Spacing” adjustment is only used in the

“Shaved Mode.” The “Shaved Product Spacing”

controls the height and length of the pile of Shaved

Product on the Transfer Conveyor. The “Shaved

Product Spacing” is set in inches or millimeters of

travel. (Illustration 59) The shorter the travel

distance the higher and shorter the pile of bunched

slices.

IMPORTANT!

The “Shaved Product Spacing” should be set

low enough to ensure that the bunched product

fits completely on the Scale Conveyors.

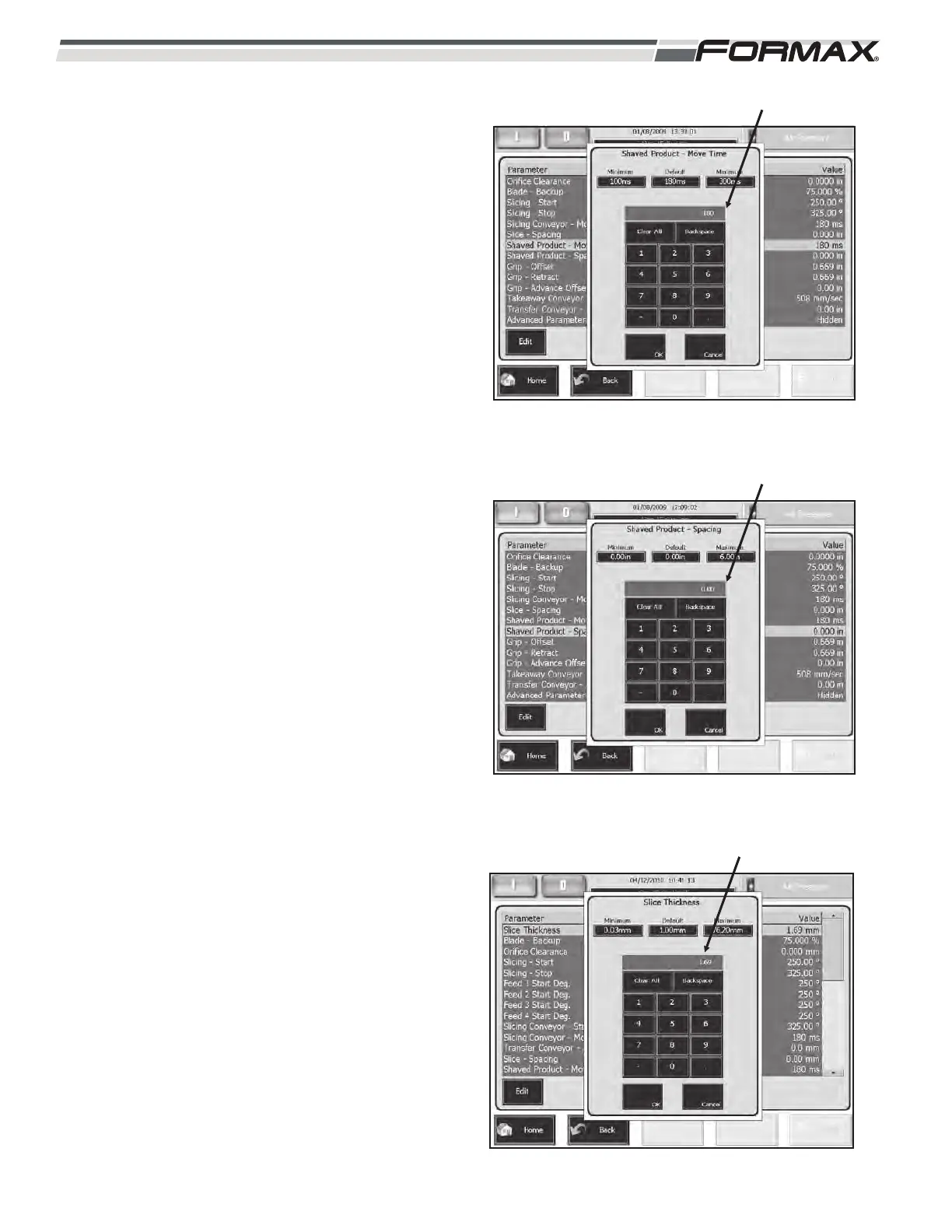

SLICE THICKNESS: The “Slice Thickness”

adjustment is used as a “Target” Slice Thickness at

the start of production. The “Slice Thickness”

should be set to make the first stack or drafts close

to the correct weight range. (Illustration 60) After

running a few “On-Weight” drafts/stacks, the

computer takes control of “Slice Thickness

Corrections.”

6-22 031914

ILLUSTRATION 58

SHAVED PRODUCT MOVE TIME

ILLUSTRATION 59

SHAVED PRODUCT SPACING

ILLUSTRATION 60

“SLICE THICKNESS” ADJUSTMENT

Loading...

Loading...