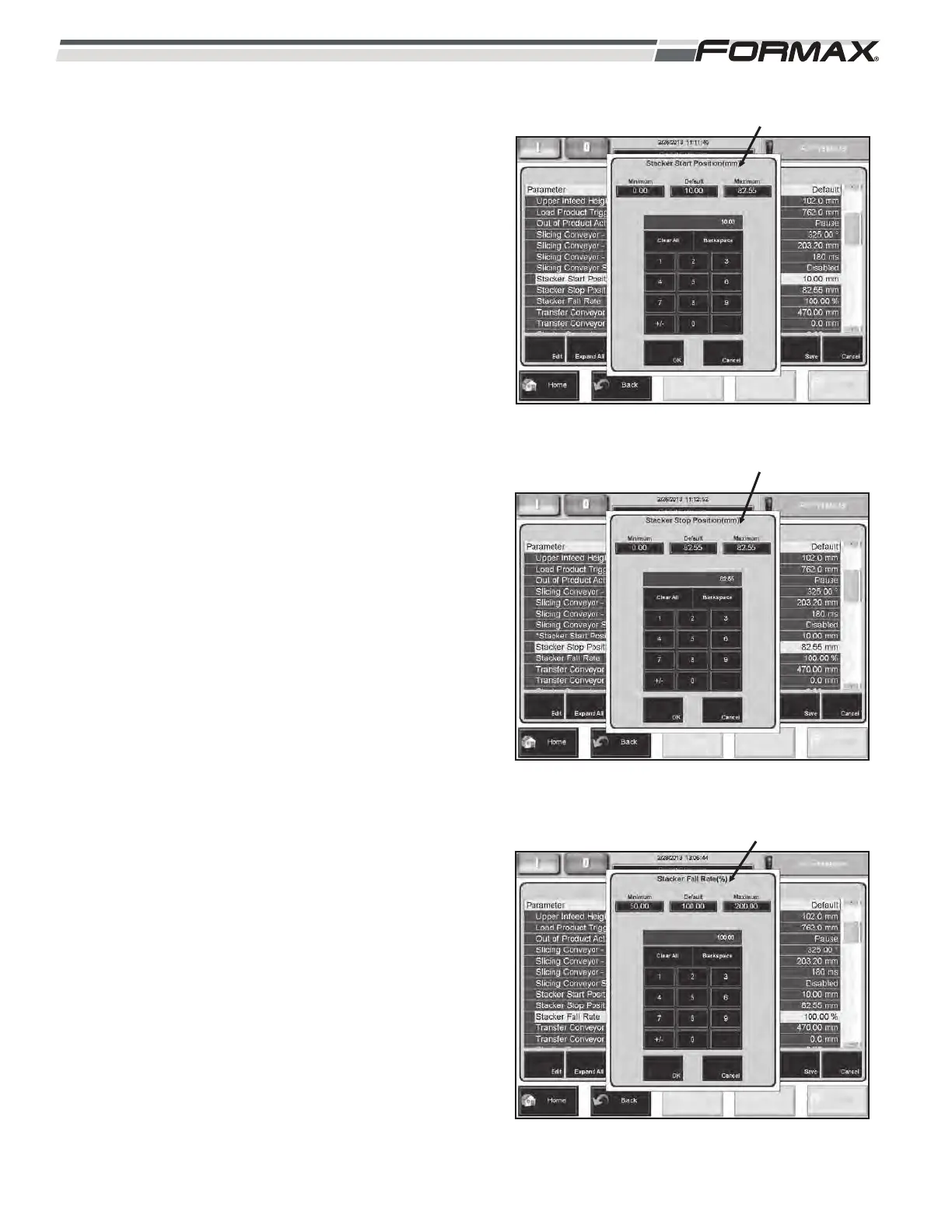

STACKER START POSITION: The Stacker Start

Position is used when slicing in the HIGH SPEED,

and ULTIMATE stack or shingle modes. Setting the

Stacker Start Position to 0.00 mm (0 in.) starts the

Slicing conveyor at the full “UP” position for the start

of each group of drafts or stacks.

When the Stacker Start Position is set to +13 mm

(0.5 in.), the Slicing conveyor will start at 13 mm

(0.5 in.) below the full “UP” position.

Setting the position too high will result in rolled over

slices and product jams. Setting the position too low

will result in shuffled stacks and offset bottom slice

problems.

For the best product quality, set the Stacker Start

Position as high as possible without causing

product jams. (Illustration 68)

STACKER STOP POSITION: The Stacker Stop

Position adjusts the stopping position of the Slicing

Conveyor after it lowers at the Stacker Fall Rate.

The product is then sent from the Slicing Conveyor

to the Transfer Conveyor. (Illustration 69)

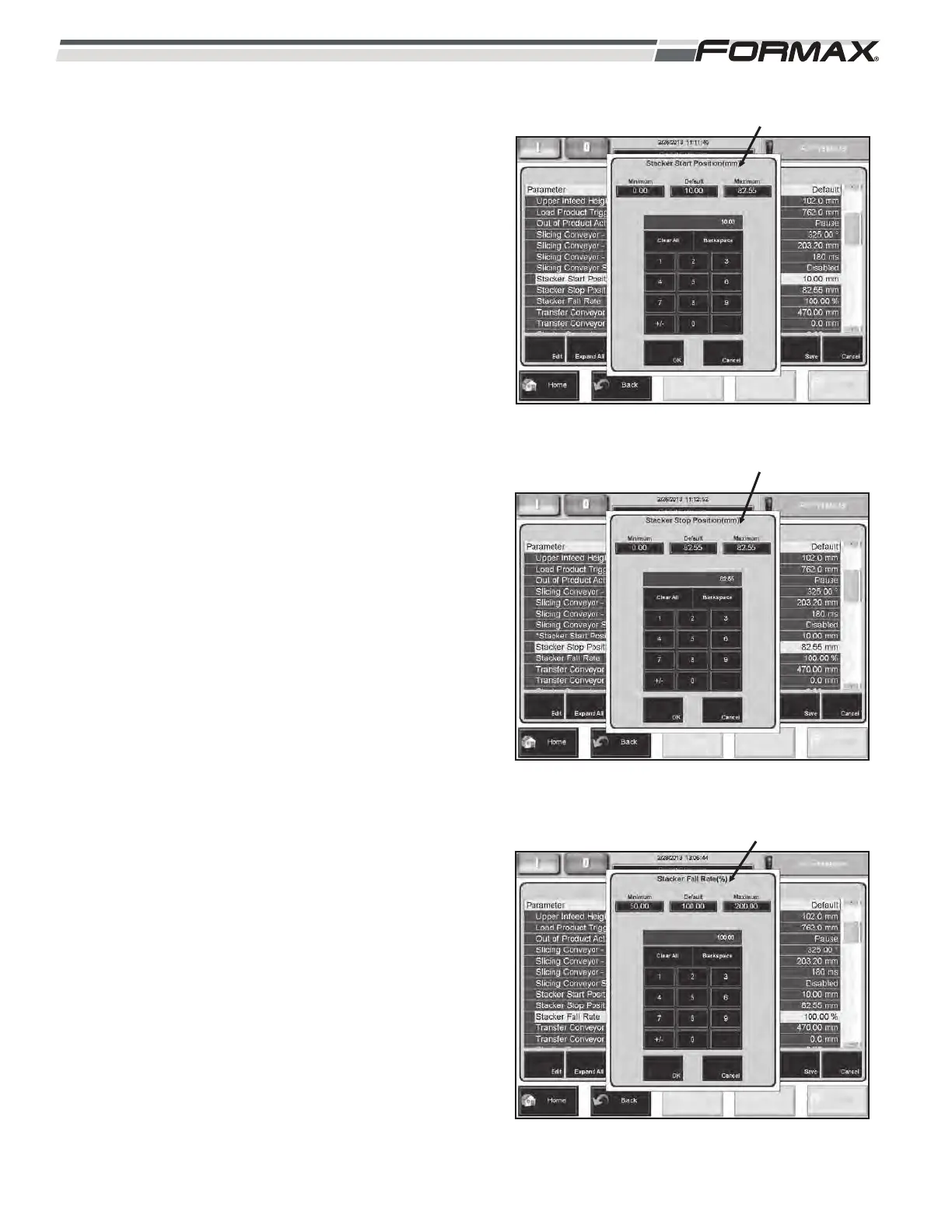

STACKER FALL RATE: The Stacker Fall Rate is

used when slicing in the Ultimate or Decel Height

stack or shingle modes. This controls the rate of

speed that the Stacker lowers as the drafts or

stacks are sliced. The lowering rate is displayed as

a percentage.

When the lowering rate is set to 100%, the conveyor

lowers at the same rate of speed that the product

feeds through the Infeed conveyors. Raising the

percentage will cause the conveyor to lower faster

than the product Infeed. A setting that is too high

can cause shuffled or fluffed stacks. A setting that is

too low can cause the product to hit the head

housing when transferring to the Decel conveyor.

A setting of about 100% will provide the best quality

stacks for most products. (Illustration 70)

6-26 031914

ILLUSTRATION 68

STACKER START POSITION

ILLUSTRATION 69

ILLUSTRATION 70

STACKER STOP POSITION

STACKER FALL RATE

Loading...

Loading...