TRANSFERRING

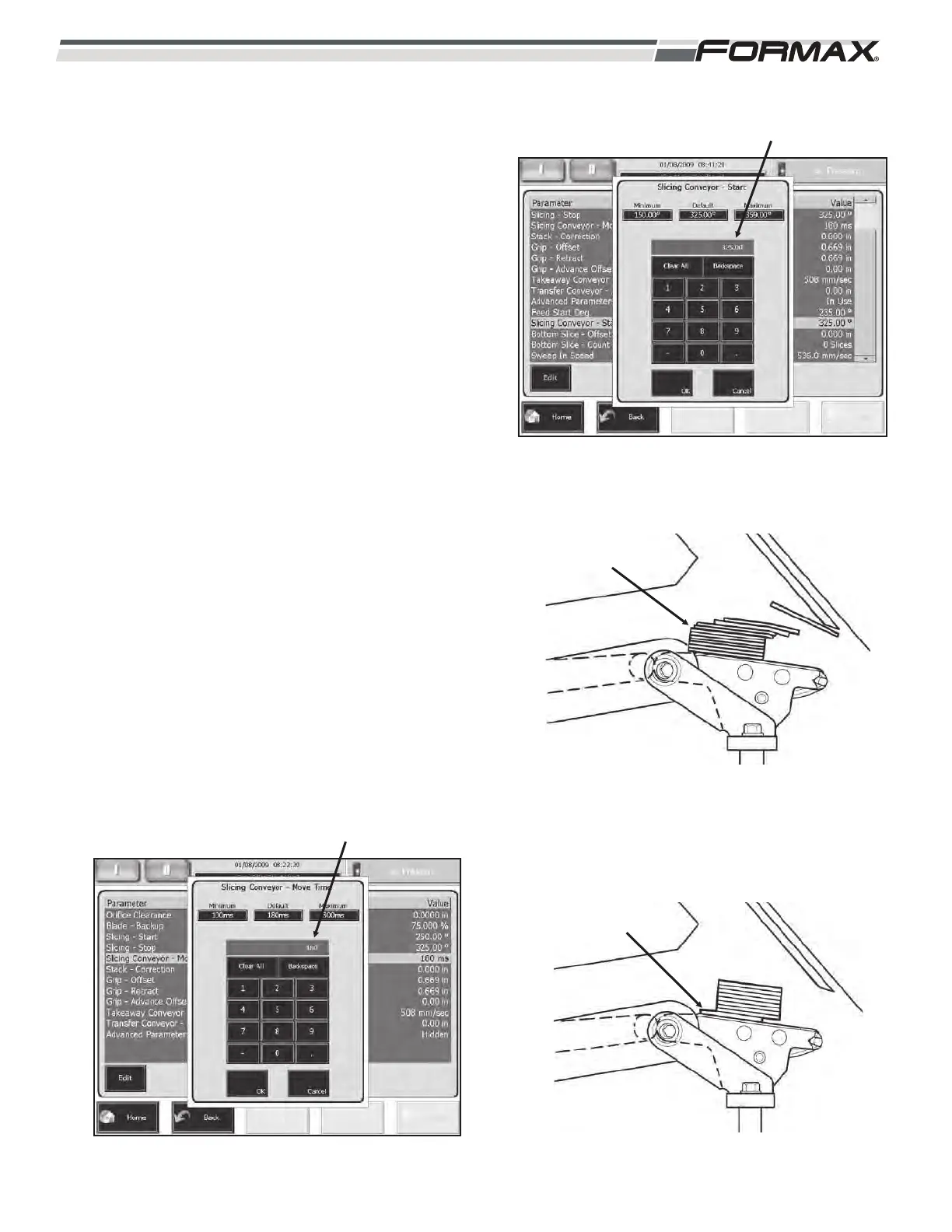

SLICING CONVEYOR START: The “Slicing Conveyor

Start” adjustment programs “when” the Slicing Conveyor

will start to transfer the completed product to the Transfer

Conveyor. (Illustration 73) The “Slicing Conveyor Start” is

set as a degree of Knife rotation from the “Home” position,

in relationship to the start of the Slicing Conveyor transfer.

If the “Slicing Conveyor Start” is set too low, the product

will transfer before the last slice has landed resulting in an

offset top slice. (Illustration 74)

If the “Slicing Conveyor Start” is set too high, the Slicing

Conveyor will still be moving when the first slice lands.

This will result in an offset bottom slice. (Illustration 75)

A “Slicing Conveyor Start” setting of 300 degrees is

normal for taller stacks. Shorter stacks can run with a

lower setting to increase the production output.

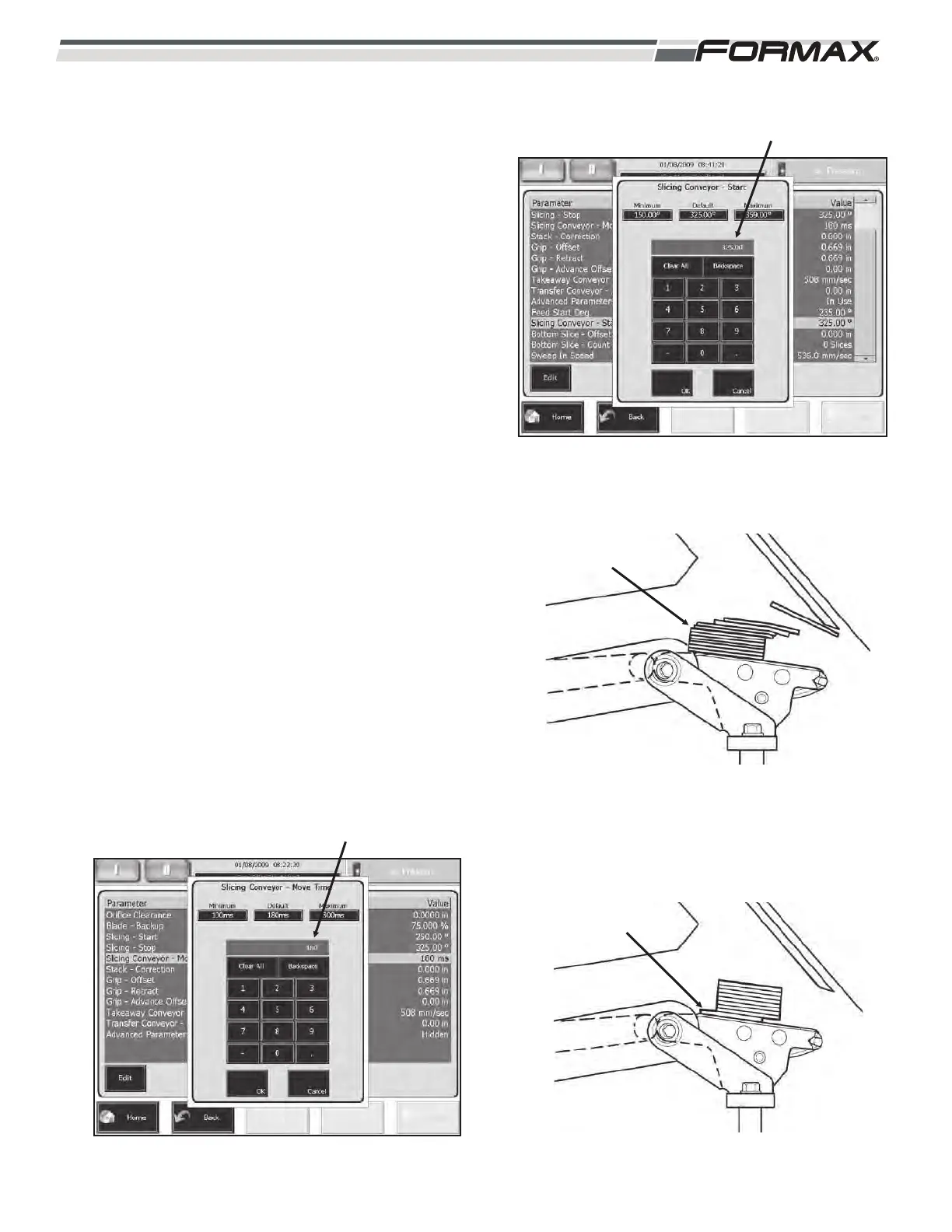

SLICING CONVEYOR MOVE TIME: The “Slicing

Conveyor Move Time” adjustment is programmed in

milliseconds and sets the acceleration rate of the Slicing

Conveyor when transferring product to the Transfer

Conveyor. (Illustration 76) If the “Slicing Conveyor Move

Time” is set to 180 milliseconds, the Slicing Conveyor will

take 180 milliseconds to go from a stopped position to full

speed. The higher the “Slicing Conveyor Move Time”

setting, the slower the Slicing Conveyor travels.

A setting of 180 to 250 milliseconds is normal for most

products.

6-28 031914

ILLUSTRATION 73

“SLICING CONVEYOR START” ADJUSTMENT

ILLUSTRATION 74

TOP SLICE

OFFSET

ILLUSTRATION 75

BOTTOM SLICE

OFFSET

ILLUSTRATION 76

“SLICING CONVEYOR MOVE TIME” ADJUSTMENT

Loading...

Loading...