CHAPTER 8

172

Troubleshooting

4/29/10 Rev G

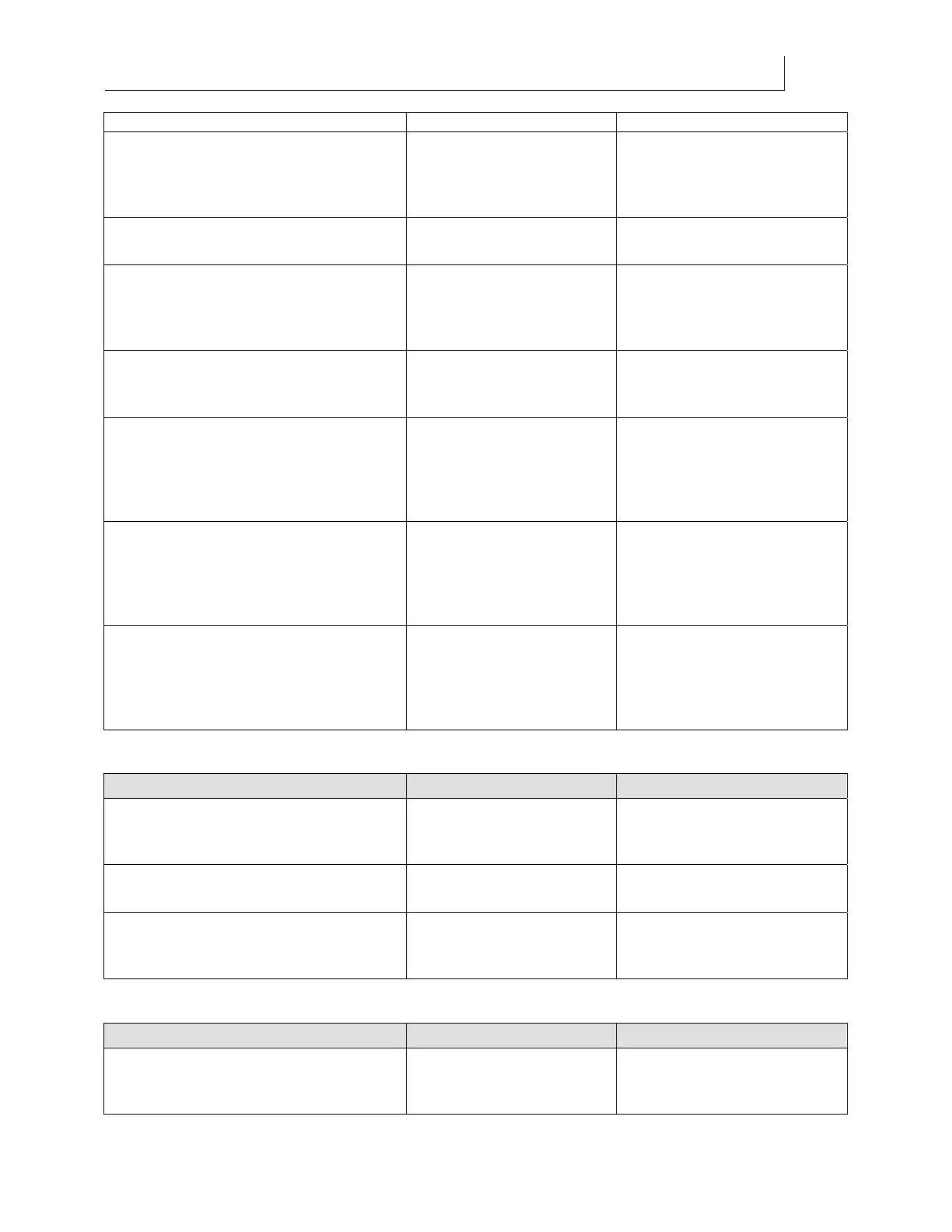

230V AC+/- 10%.

Is the environment within the strict

specifications?

Ensure that the

environment is within the

strict guidelines for

temperature and humidity.

See “Ambient conditions” on

page 16.

Is the environment marginally within the

specifications?

Try running in High Lamp

Spec mode.

See “Lamp Spec mode” on

page 63.

Are you using Gerber-approved

material?

Use Gerber-approved

material or try running in

High Lamp Spec mode.

See “Choosing a material

type” on page 44 and See

“L

amp Spec mode” on page

63.

Is the print oversaturated with ink,

especially on heavy black areas?

Redesign the job to

substitute single color black

for 4-color (CMYK) black.

See design program

documentation.

Is the lamp aged or damaged? Lower the maintenance

shelf and look up in the

gantry to examine the lamp

for black discoloration.

Replace lamp if necessary.

Seek technical assistance if the

lamp appears to need

replacement.

Is something blocking the UV light? Lower the maintenance

shelf and look up in the

gantry to see if jammed

material or tape is stuck to

the lamp or reflector.

Remove any jammed material

or tape.

Is there a lamp temperature issue. Lower the maintenance

shelf and look up in the

gantry to see if the

thermistors are at the

bottom and facing down.

Seek technical assistance.

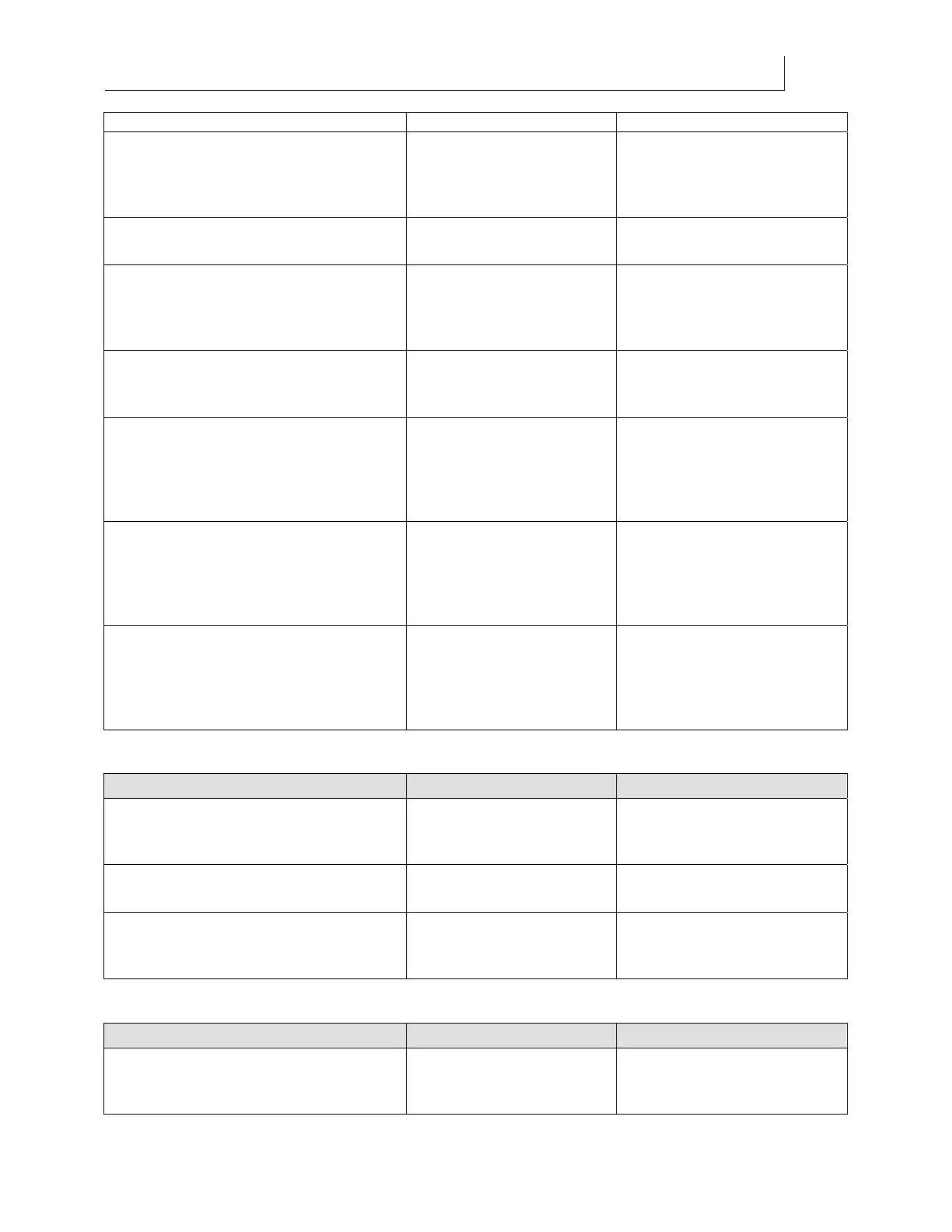

First few inches (50-100cm) of the job is not curing

Problem Solution Notes

Did you use more than one drop of Daily

Maintenance Solution when swabbing

the printheads?

Use only 3-5 drops of Daily

Maintenance Solution per

swab.

See “Clean Heads Procedure”

on page 84.

Is the ambient environment marginally

within the specifications?

Try running in High Lamp

Spec mode.

See “Lamp Spec mode” on

page 63.

Are you using Gerber-approved

material?

Use Gerber-approved

material or try running in

High Lamp Spec mode.

See “” on page 44 and “Lamp

Spec mode

” on page 63.

One side of the print is not curing well

Problem Solution Notes

Did you use more than one drop of Daily

Maintenance Solution when swabbing

the printheads?

Use only 3-5 drops of Daily

Maintenance Solution per

swab.

See “Clean Heads Procedure”

on page 84.

Loading...

Loading...