CHAPTER 5

75

Printing Jobs on the GERBER SOLARA ION

4/29/10 Rev G

6 Using the new page size, send the job

to the printer and start printing by

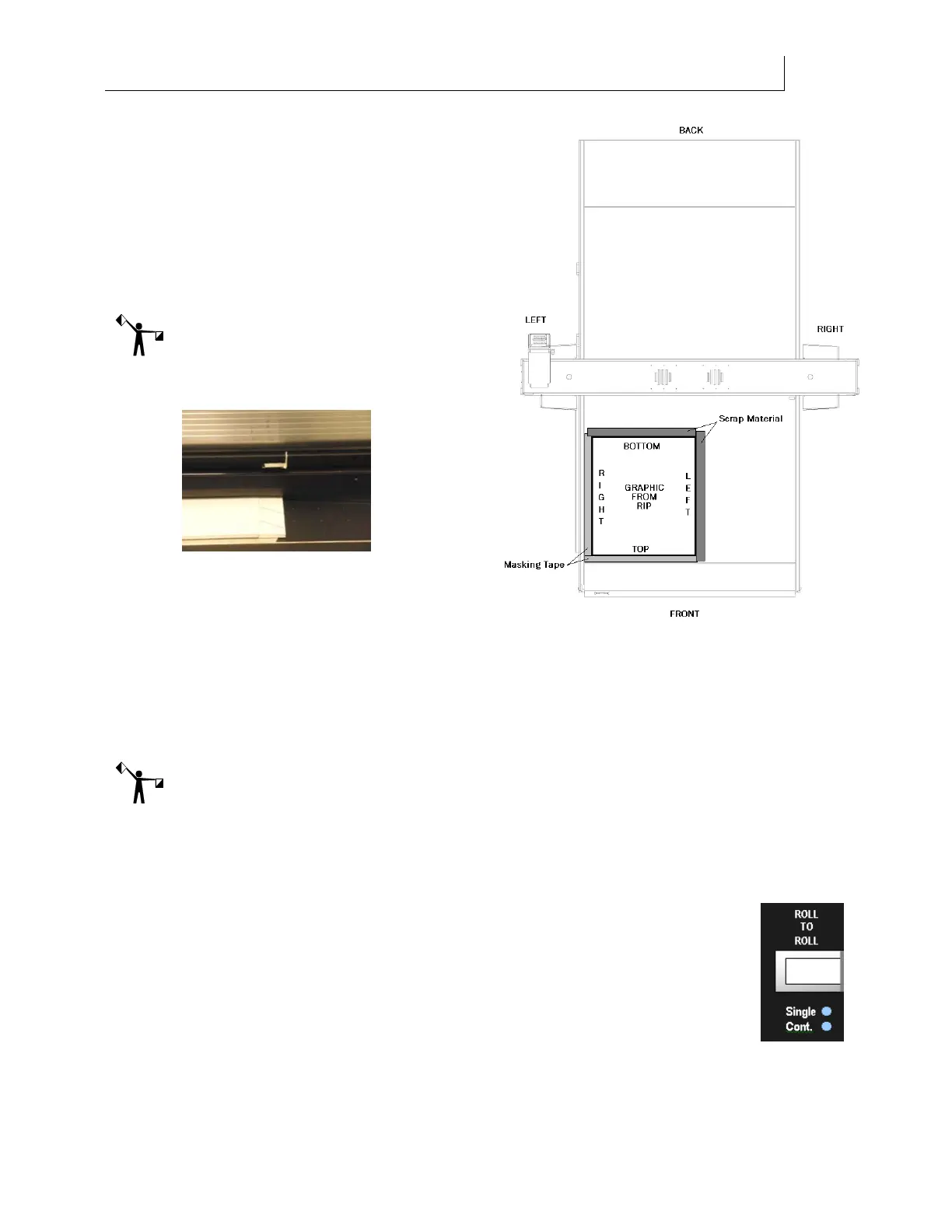

pressing the Run Job button in the

Solara ion. When the Solara ion asks

you to move the UV shield, move the

UV shield so that it is aligned with the

scrap material, not the substrate’s

edge.

Note: It is important to align the UV

shield with the scrap material so that the

printer does not inadvertently print on the

shield and result in ink build-up that can

cause head strikes.

7 When the first side is complete, flip the

sign blank over left to right (if the top

of the job is located at the front of the

printer as shown in the previous

illustration). Place the sign blank in the same location as the first side, completely

inside the masking tape and scrap material. Repeat printing on this side.

8 Remove all masking tape and scrap material so that the ink does not build up too high

and scratch the heads.

Note: The scrap material on the back and right sides of the sign blank should be removed after

every job; the masking tape at the edges of the table can be used a few times since it is thinner

than the sign blank. Just be sure to remove and replace the tape whenever the ink build up

starts to approach the height of (or is higher than) the sign blank on which you are printing.

Printing multiple Roll-to-Roll jobs in Continuous mode

Continuous mode lets you run several jobs in Roll-to-Roll mode without having to

press Run Job between each one. When one job finishes, the next job begins

immediately on the same material loaded in the printer. When all jobs that have

been sent are completed, the printer waits for another job and begins printing as

soon as it is received. Continuous mode is designed for printing multiple jobs on

the same rolled material.

In continuous mode the operator is not prompted to turn on the platen hold-down

vacuum at the start of a job. The operator must turn the vacuum on or off as appropriate using

the LOAD/UNLOAD key.

Loading...

Loading...