CHAPTER 4

50

Loading Inks and Materials

4/29/10 Rev G

Using the material roller

When loading roll material onto a material roller, place the roll on a flat surface. Never load a

roll of material onto a roller standing on end as it can damage the material and the roller.

CAUTION: Material rolls can be heavy. Maximum roll weight is 100 lbs./45.36 Kg.

Take care when lifting and loading the material rolls.

CAUTION: Be careful not to pinch your fingers in the roll feed system when

loading the material.

To load roll material onto the material roller

1 Remove the material supply axle from the assembly and then remove the left core

flange from the axle.

2 Lay the roll of material on a flat horizontal surface and insert the material supply axle

into the roll. Insert the axle until the material tube fits firmly against the fixed right

core flange.

Note: Make sure that the material is properly oriented when inserting the roller so that the

material enters the printer print side up. From the back of the printer, the adjustable flange will

be at the left end of the roll.

3 Insert the left core flange onto the axle until it fits firmly against the material tube.

4 Tighten the white thumbscrew to hold the flange in place. Do not over-tighten the

thumbscrew.

5 Standing at the roll-to-roll end of the printer, hold the material roll loaded on the roller

with the adjustable flange to the left and place it on the printer.

Note: The material on the supply roll must not be slack to insure proper media feed. Re-roll

around the supply roll if necessary. Also check the tension on the feed roll brake.

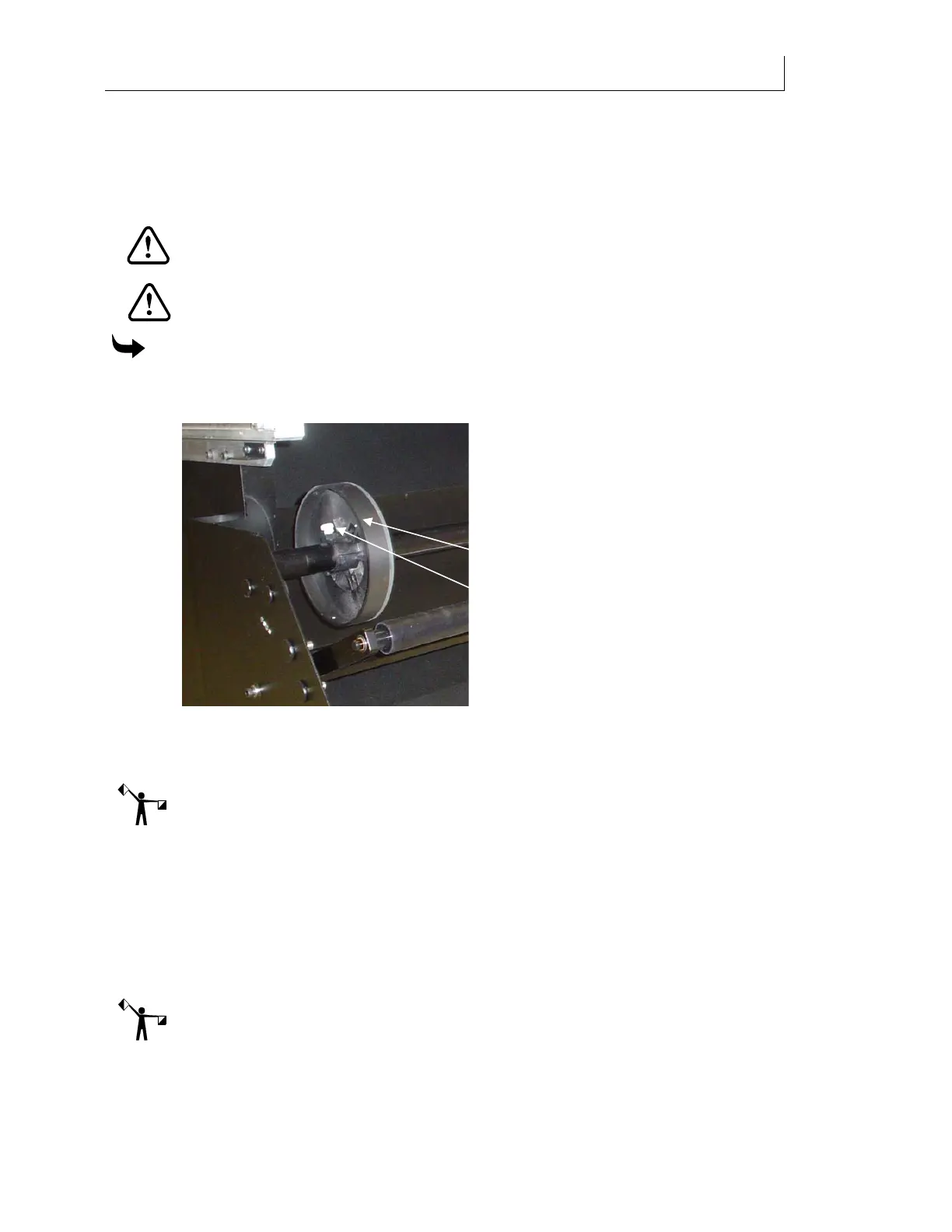

Core flange

Thumbscrew

Loading...

Loading...