CHAPTER 4

49

Loading Inks and Materials

4/29/10 Rev G

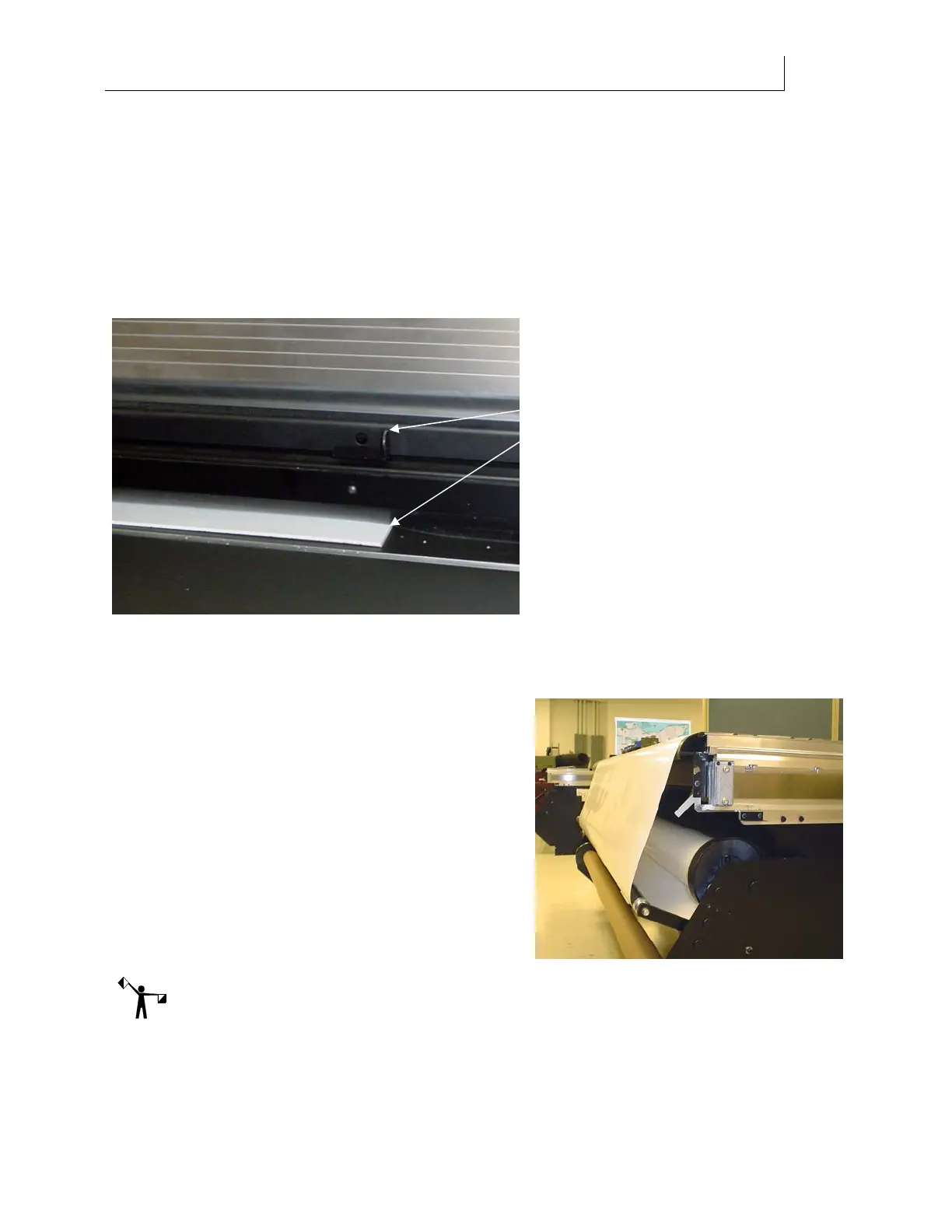

Adjusting the UV shield for rigid material

The Gerber Solara ion comes with a sliding UV shield that protects the printer from over-

exposure to UV light. Material hold-down devices are not required for rigid material.

Once the rigid material is loaded on the flat bed, grasp the sliding UV shield by the handle and

position it so that the right edge of the handle aligns with the right edge of the rigid material.

The shield is not used to help hold down the material when printing, but to protect the printer

against over-exposure to UV light. The UV shield can move up and down the entire length of

the carriage gantry to adjust to varying material widths.

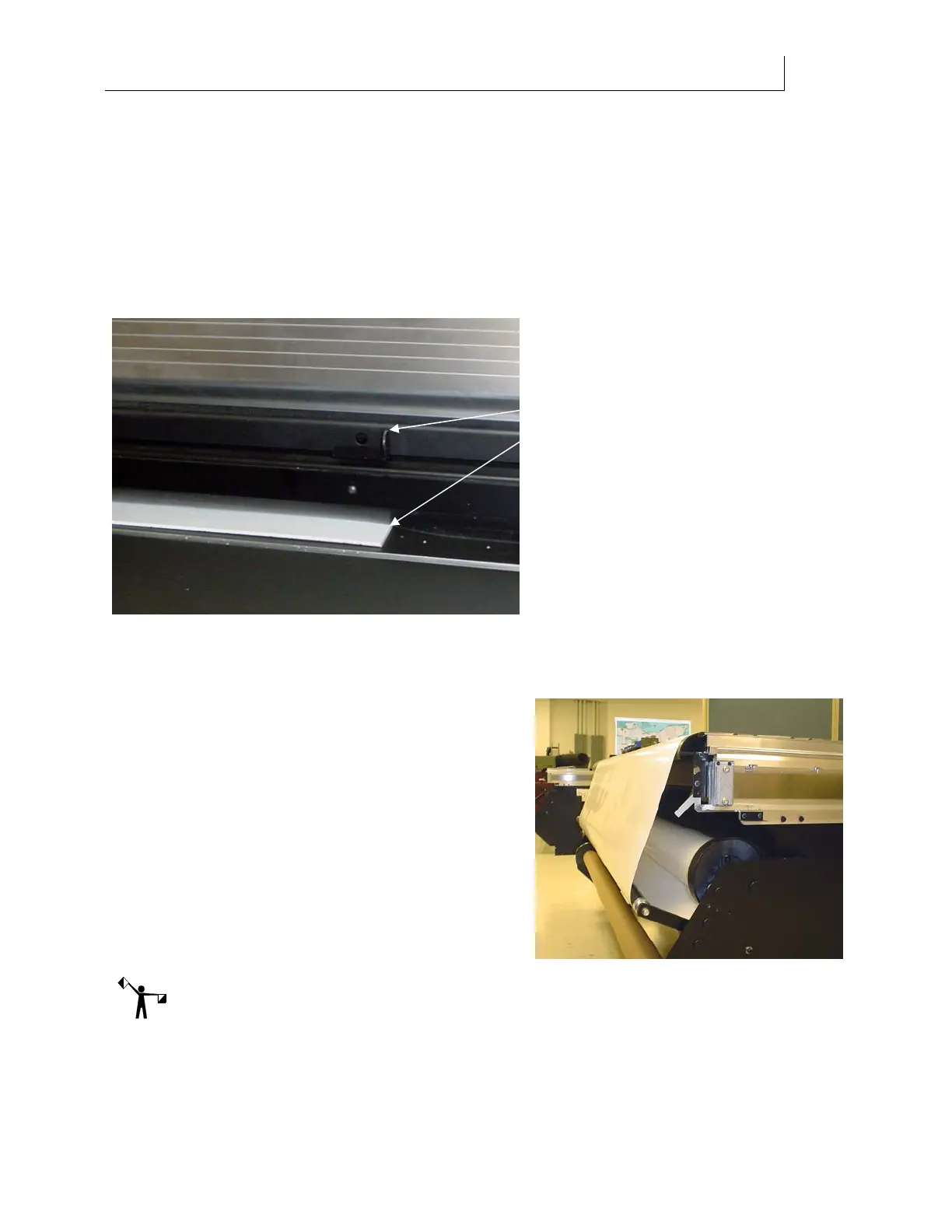

Loading roll material in the Roll-to-Roll configuration

Roll material refers to rolled or flexible sheet material.

The rolled or sheet material can be made of many

different materials as long as it is qualified for use

with the Gerber Solara ion. When printing on roll

material it is recommended that you use the optional

roll-to-roll configuration which includes a winder.

Using rolled material effectively involves the

following steps:

Loading roll material onto a material roller

Loading roll material into the printer

Loading and removing material from the

winding unit

Note: The Gerber Solara ion does not detect material size (length or width). Material size must

be set in the RIP and the user must be careful to load the correct size material to accommodate

the job. The smallest acceptable roll material width is 24"(61cm).

Line up this ed

e of

sliding UV shield

handle with right

edge of material.

Loading...

Loading...