(4) HECU voltage of 10 ~ 12V is preferred during exhaust mode operation. As battery on

vehicle is used when using diagnostic instruments, there should be no problem. (If

exhaust mode operation is repeated with high voltage, ECU coil may be damaged.)

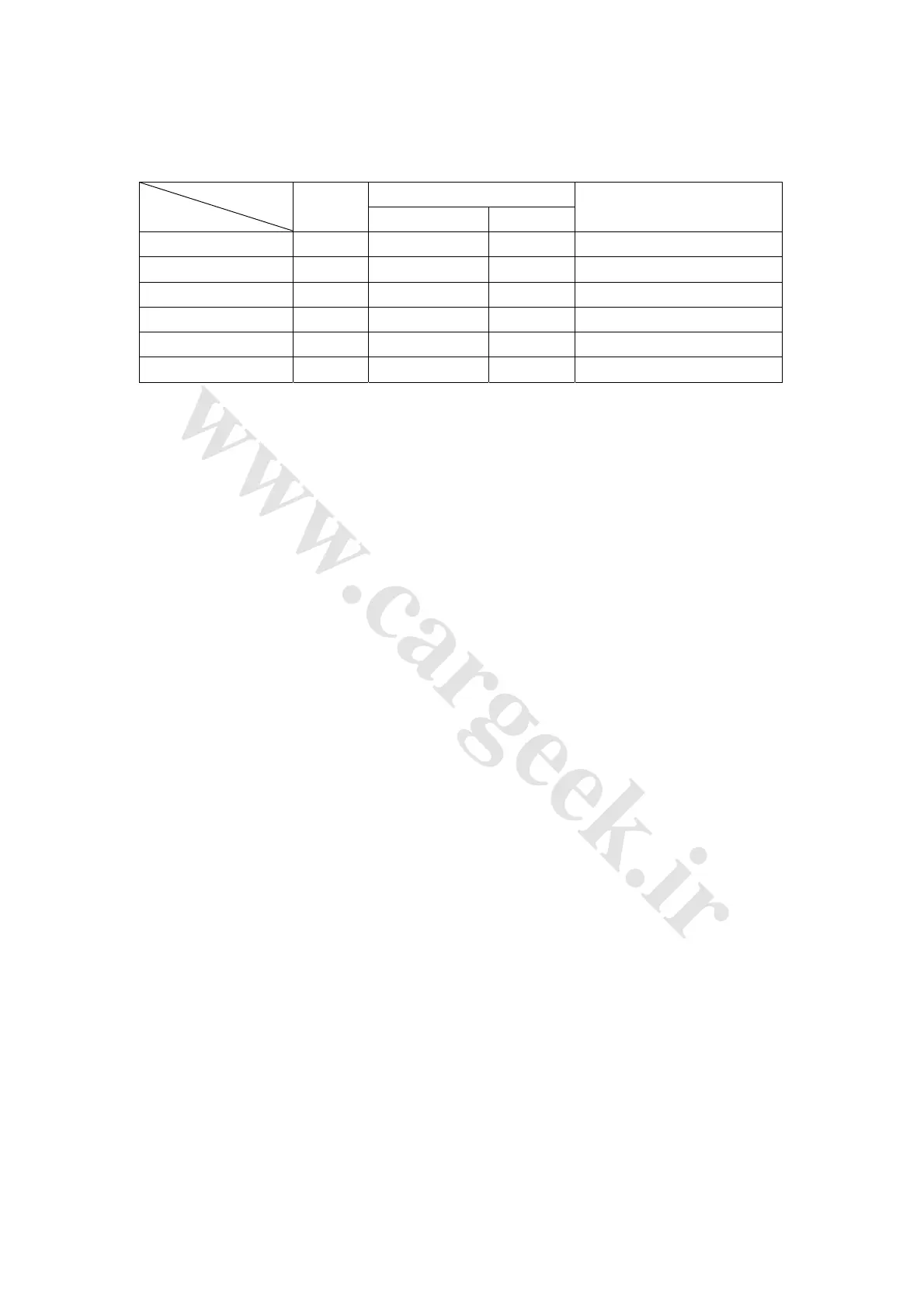

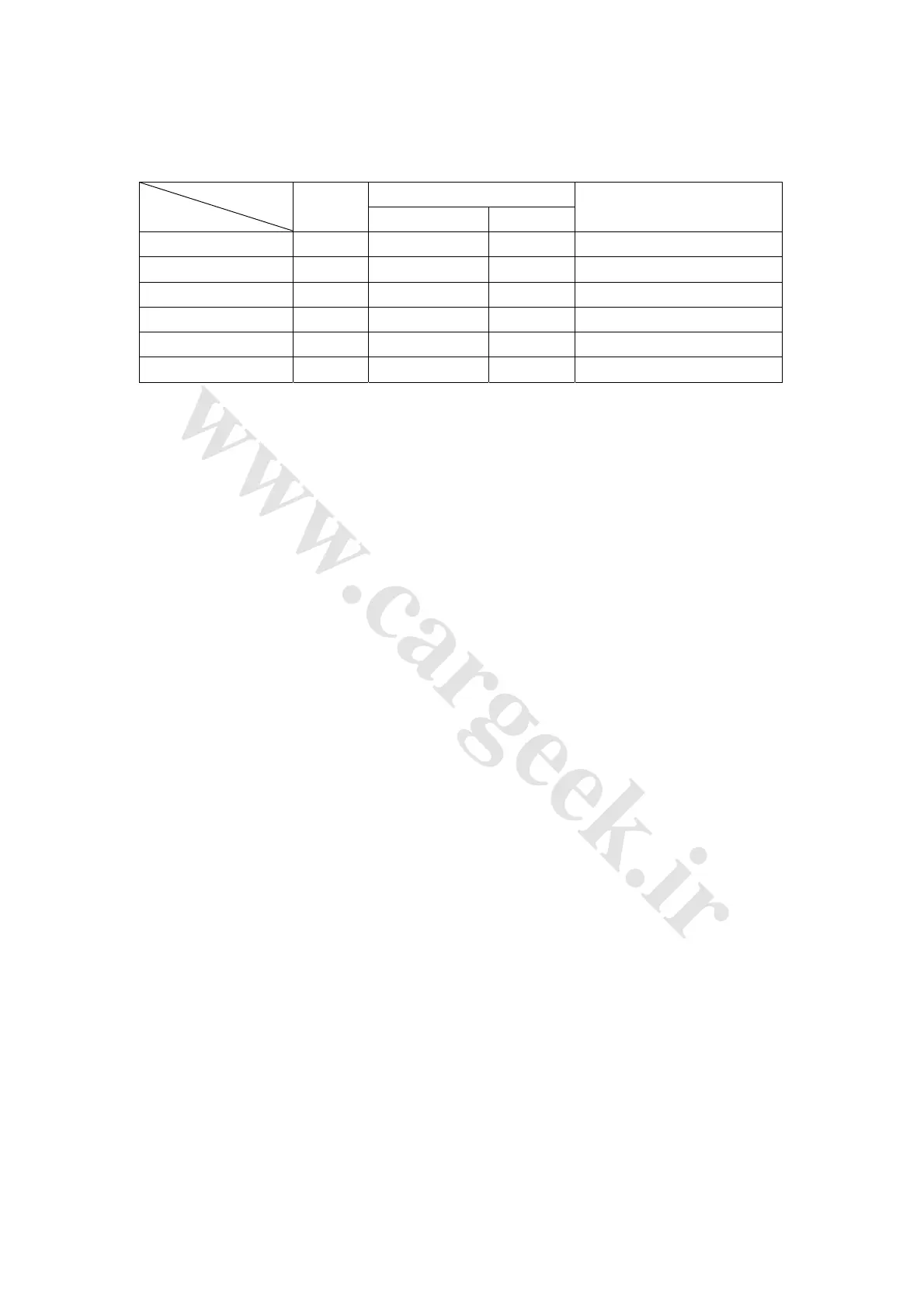

4. Exhaust fault confirm methods (Table 3-21)

Table 3-21

Leak experiment Difference

Type

ECU

operation

Excessive leak Minim leak

Remark

Case 1 Normal O.K O.K Normal operation, no rework

Case 2 Normal O.K N.G Abnormal operation, rework

Case 3 Normal N.G N.G Abnormal operation, rework

Case 4 No O.K O.K Abnormal operation, rework

Case 5 No O.K N.G Abnormal operation, rework

Case 6 No N.G N.G Abnormal operation, rework

Case 1: Condition after normal operation.

Case 2: Bad connection condition of brake gear (HECU hole/brake pipe/brake hose);

rework is necessary.

Case 3: Similar to Case 2; but severe leak may make rework unable to be carried out.

Case 4: Exhaust fault of HECU internal circuit; spongy pedal or enlargement of pedal

play may occur after one ABS operation. Rework is necessary.

Case 5: Synthetic fault of Case 2 and Case 4; rework is necessary.

Case 6: Similar to Case 5; but severe leak may make rework unable to be carried out.

5. Measures for exhaust and filling faults (dry inside of brake system).

(1) Fault confirmation. Confirm all connections from the master pump to wheel slave

cylinder: HECU hole, brake connection, brake hose connection, bleed screw of caliper

and drum brake, etc.

(2) Reassemble according to specification for leak prevention after fault confirmation.

(3) Connect the reassembled equipment to connecting piece of pin 25 of ECU or

connect diagnostic instrument to wire K (pin 7). Special wire should be applied when

connecting to connecting piece; vehicle circuit should be connected or started when

connecting to wire K (pin 7). The oil can of the master pump should be connected to

uninterruptible brake oil supply equipment, or there should be always brake oil in the oil

can.

(4) Diagnose HECU with the reassembled equipment and diagnostic instrument to

check whether there is still a DTC. DTC should be deleted first if it exists. (If fault of item

(1) is not confirmed, fault confirmation is also necessary.) If DTC can not be deleted,

refer to “DTC Check Table” in Section 24 (If there is fault in HU, motor and ECU,

exhaust and filling in HECU can not be operated).

(5) After stepping on the brake pedal, open the bleed screw on the caliper or drum brake

to exhaust the inside air. This operation should be carried out for all wheels before that

the brake fluid exhausted through the bleed screw contains no air and the brake pedal is

hard enough. When using the reassembled equipment that can form vacuum or is filled

with brake fluid, refer to item (10).

(6) Operate the exhaust mode with the reassembled equipment or diagnostic instrument

and step on the brake pedal, if there is no reaction force, repeat stepping on and

releasing the pedal until the exhaust mode is finished. (Exhaust mode: repeat the

process of start and stop of normally closed solenoid valve with interval of 2 seconds for

1 minute, and keep motor working. The repeat of stepping on and releasing of pedal

should be carried out on the normally closed solenoid valve while motor is operating.)

Loading...

Loading...