Section V Precautions of Air Conditioning System

I. Apply pure R-134a refrigerant

(1) Must apply authentic R-134a cooling medium with qualified standard of component, moisture

content, foreign matters and foul gas. 13.6kg canned cooling medium is recommend for service

station;

(2) Refrigerant charge must comply with the provision of complete vehicle factory, both excess

and lack will reduce the refrigerating effect.

(3) Before injecting refrigerant, completely check whether every pipe O-ring seal is in good

condition and whether leakage of every part exists;

(4) Before compressor starts working, can inject from the low pressure side and high pressure side

simultaneously; after compressor starts working, can only inject from the low pressure side slowly;

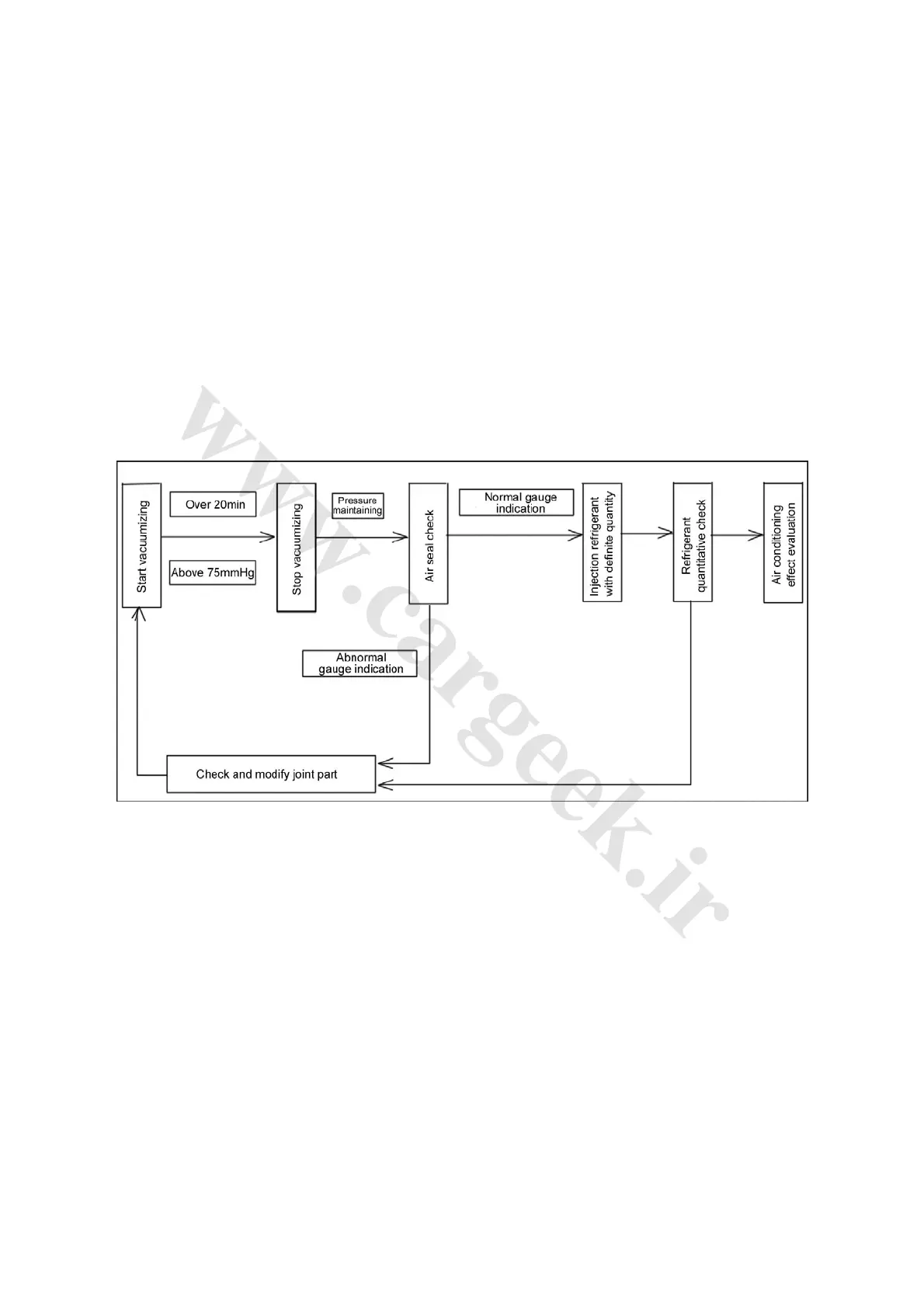

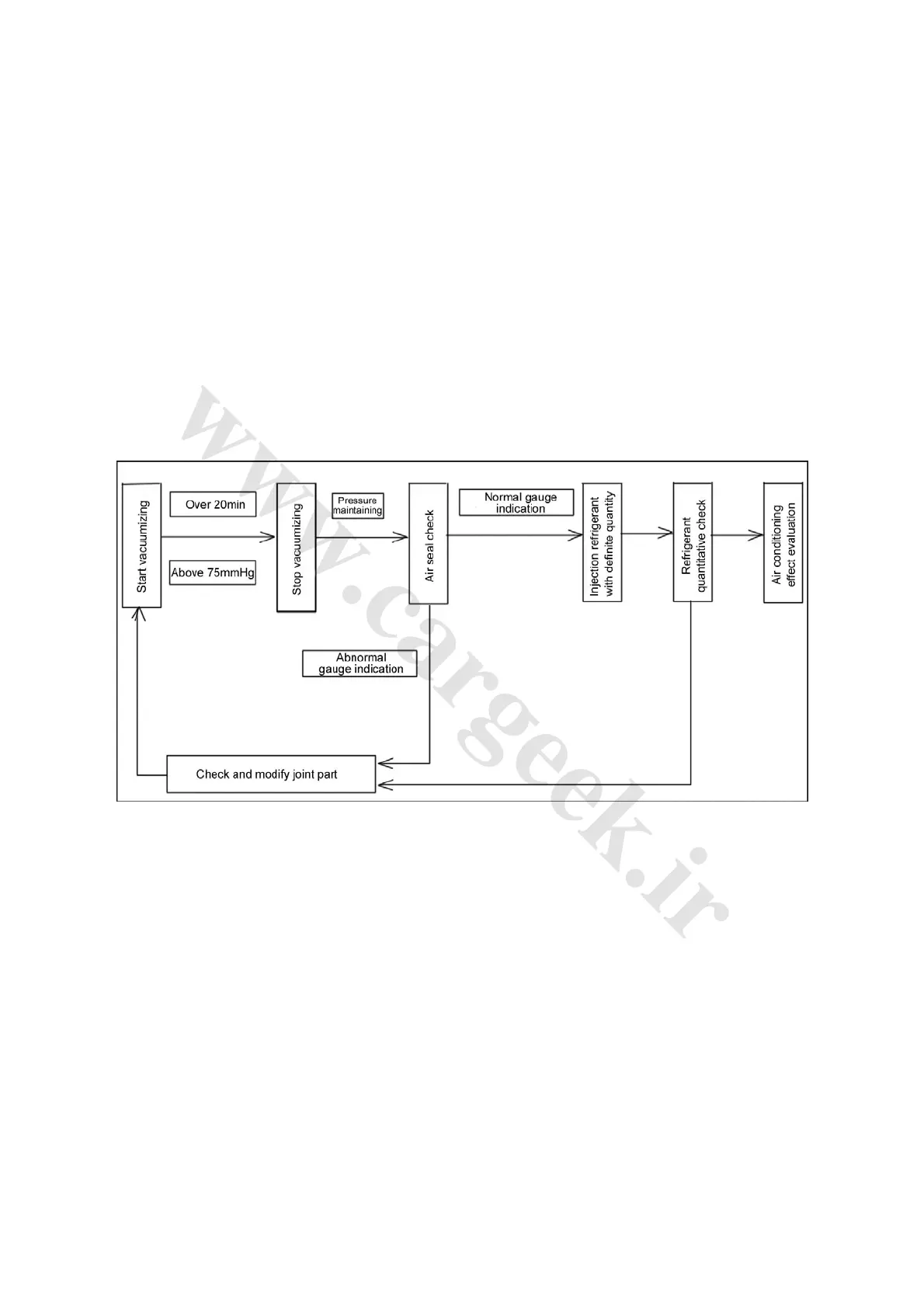

Figure 6-42.

Figure 6-42

(5) After filling in R-134a cooling medium, apply electronic leak detector for leakage inspection.

II. Add lubricant correctly

1. Must apply lubricant with type and brand stipulated by compressor manufacturer. Do not mix

lubricant of different types and brands, or compressor will be damaged;

2. The injection quantity should full comply with the stipulation. Lubricant has bad influence on

heat transmission, excessive lubricant will reduce the air conditioning effect greatly; generally, it is

not necessary to add lubricant, for that has been injected by compressor manufacturer; properly

add lubricant when replacing parts: condenser 20ml; drier-receiver 30ml; evaporator 30ml;

pipeline 10ml/m.

3. Lubricant has great water absorption power, thus it is necessary to reduce the time of contacting

air as much as possible;

4. Before injection, quality of lubricant in pipelines should be checked first. If lubricant is black or

carbon granule precipitation exists, clean and blow the entire air conditioning system completely,

Loading...

Loading...