2. Start failure of the engine

Common trouble location:

1. No fuel in the tank; 2. Fuel pump; 3. Rotation speed sensor;

4. Ignition coil; 5. Mechanical part of the engine

Diagnosis Flow

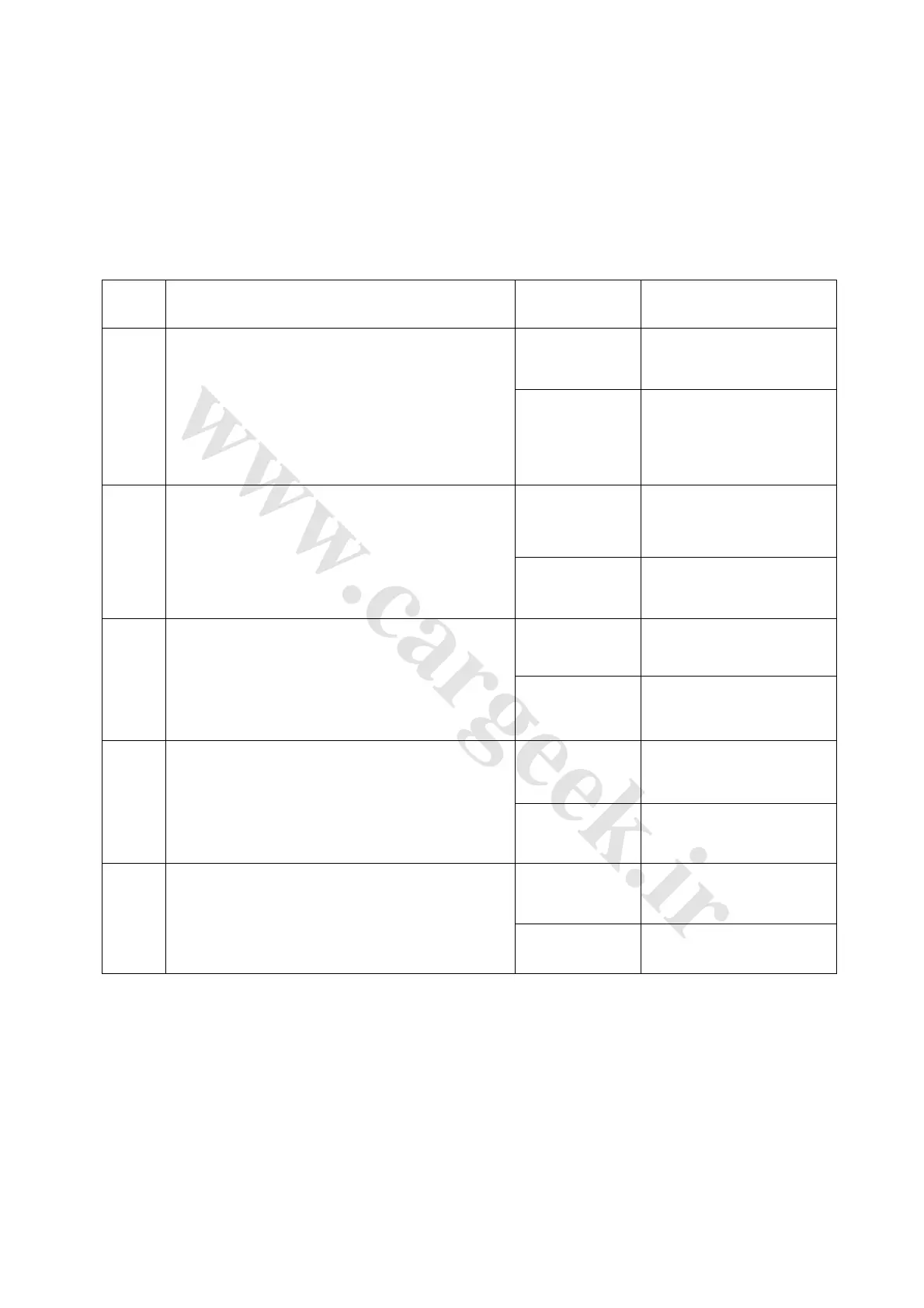

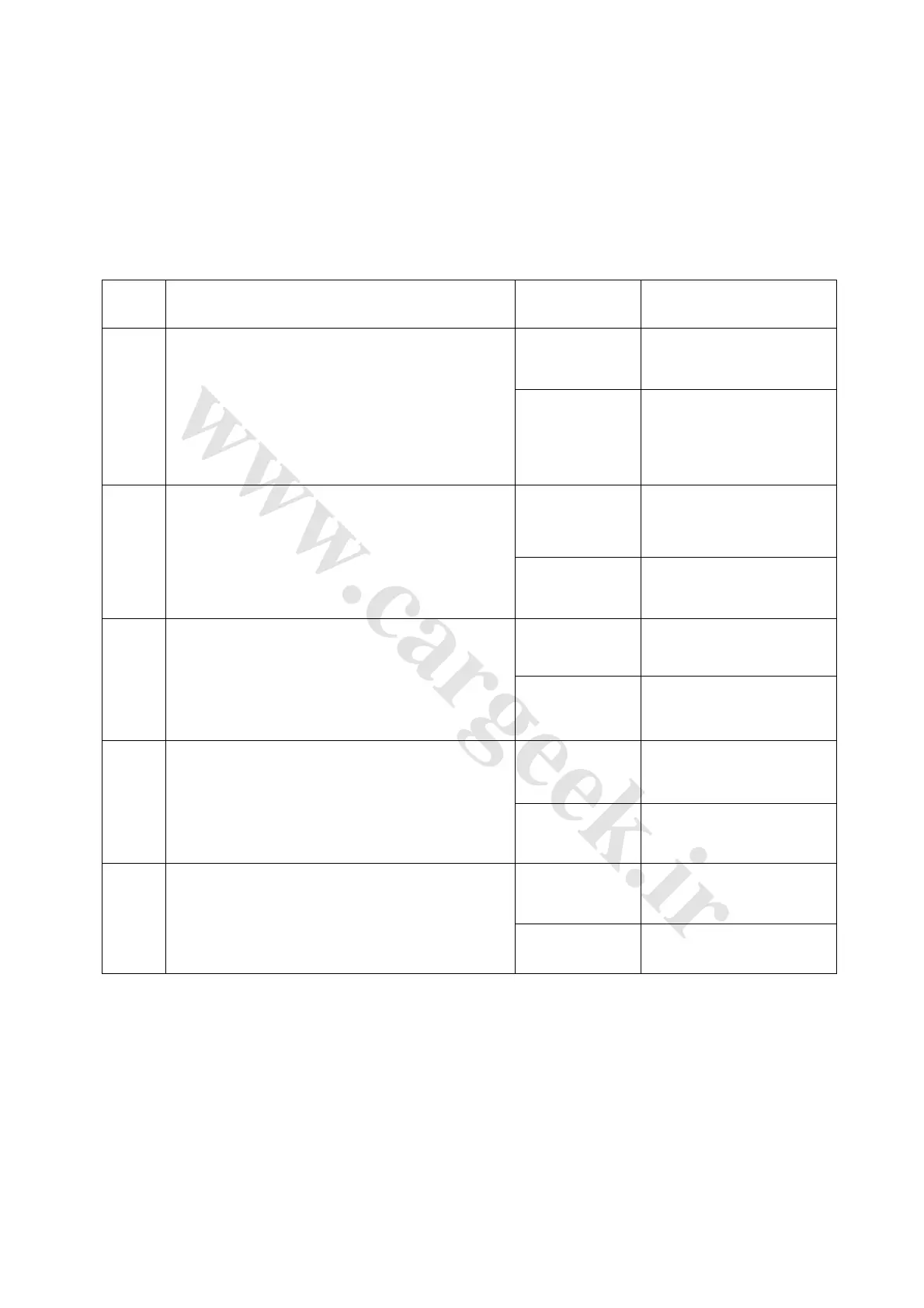

Table 1-68

S/N Operation Test Results Actions

Yes Next step

1

Connect the fuel pressure gauge (the connection

point is the front end of the intake pipe of the fuel

distribution pipe assembly), and start the engine.

Check if the fuel pressure of the engine under full

working condition is about 350kPa.

No

Check and repair fuel supply

system

Yes Next step

2

Connect the electronic injection system diagnostic

instrument, and check the rotation speed of the

engine. Start the engine, and check if there is rotation

speed signal output.

No

Check and repair rotation

speed sensor line

Yes Next step

3

Draw out the wire of one of the cylinders, and connect

with the spark plug. Keep the electrode of the spark

plug about 5mm from the engine body. Start the

engine, and and check if the blue white high voltage

fire is produced.

No

Check and repair ignition

system

Yes

Remove the mechanical

troubles for the engine

4

Check the pressure of each cylinder of the engine.

Check if the pressure is enough.

No Next step

Yes Diagnosis help

5

Connect the electronic injection system adapter. Turn

on the ignition switch. Check the power supply of the

pin 12#, 13#, 44#, 45#, 63#. Check the grounding of

the pin 3#, 51#, 53#, 61#, 80#. Are they OK?

No

Check and repair relevant

line

Loading...

Loading...