3. Check the tachometer

Start the engine at DC 13.5V±0.5V, ambient temperature 25 ±5 , ℃℃externally connect with

trouble diagnostic instrument to measure the rotation speed, the value measured should

correspond to the instrument display within a permissible range, as shown in the table below.

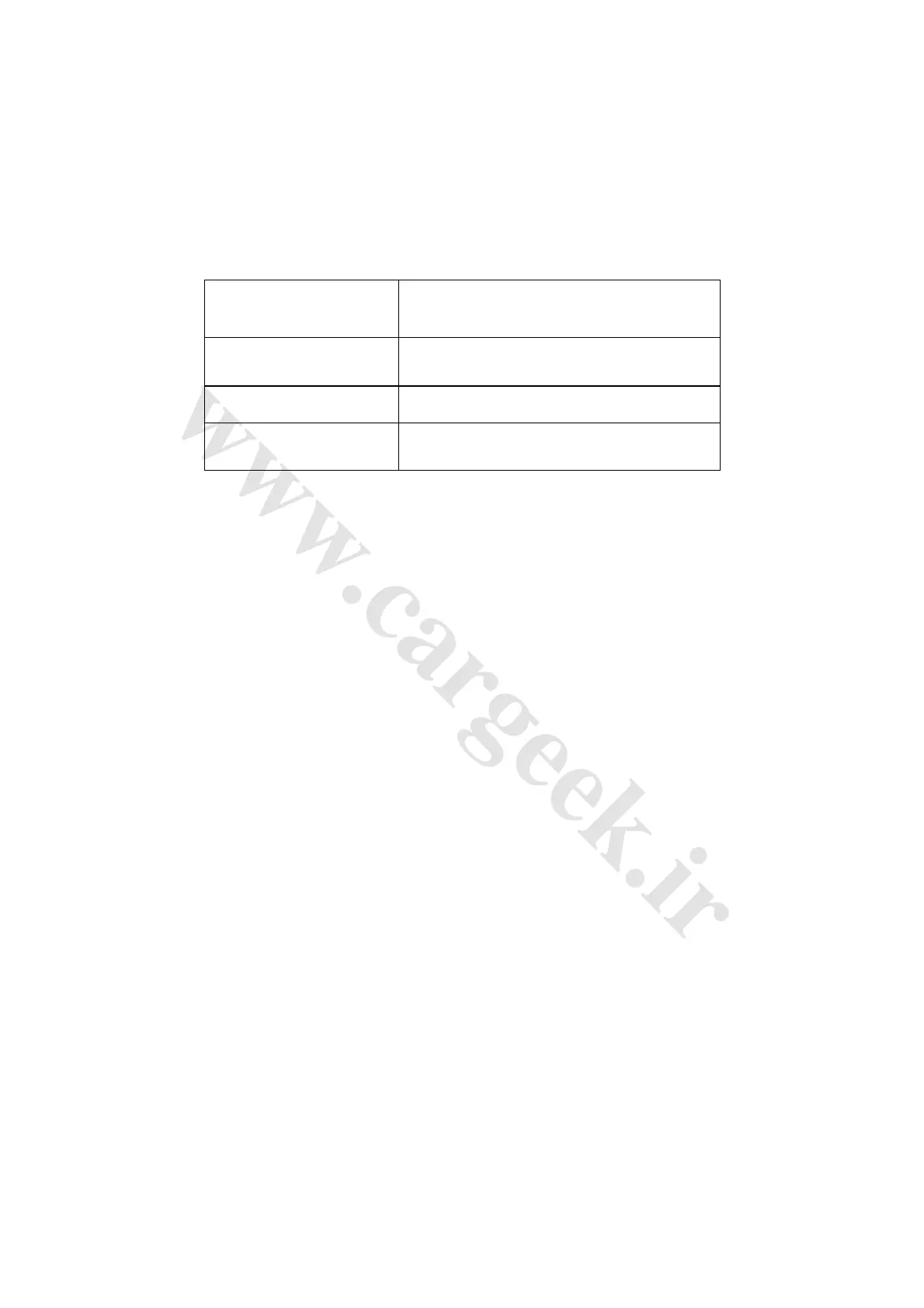

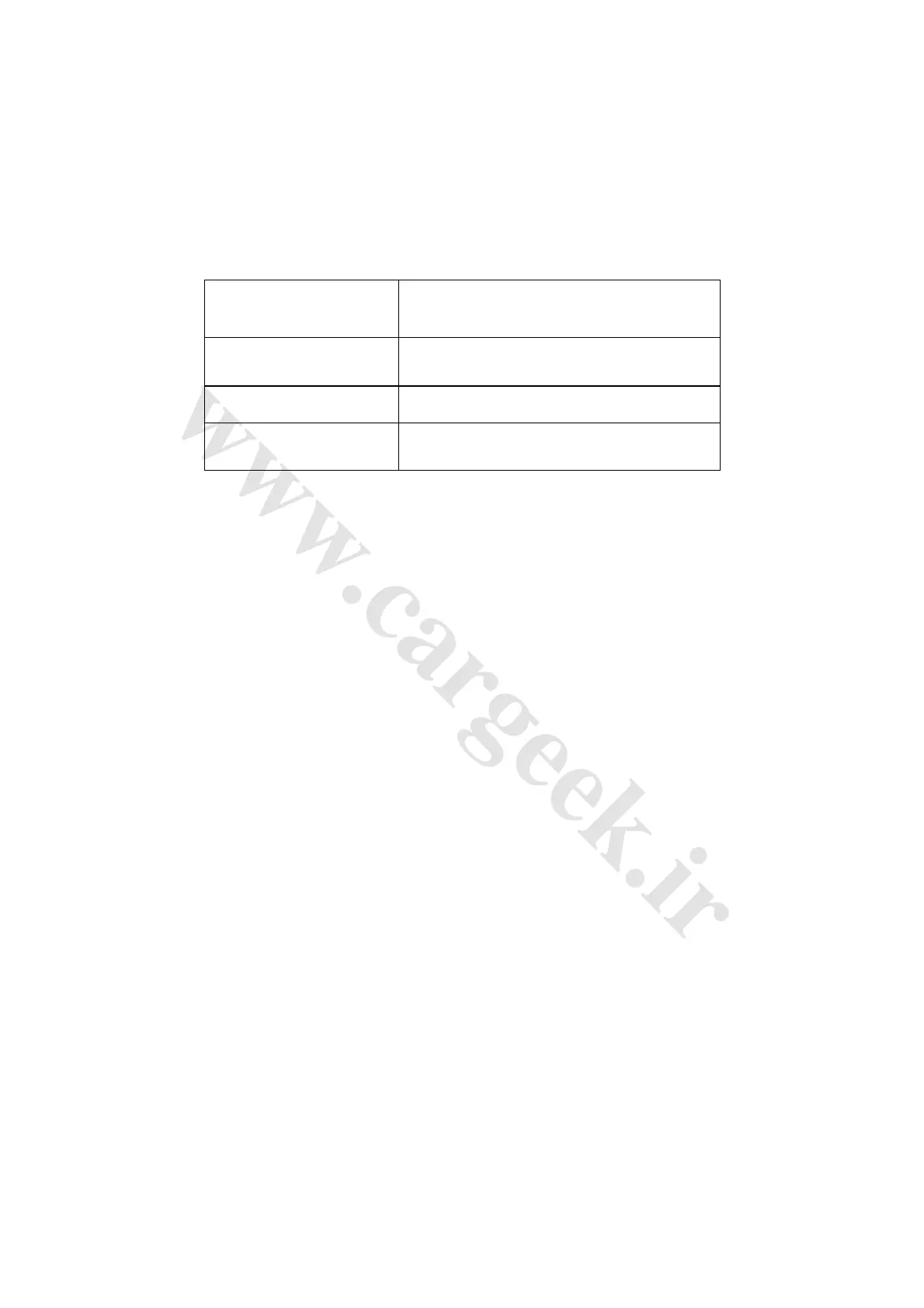

Tachometer permissible range (see Table 4-5)

Table 4-5

Value measured (rpm) Instrument display (rpm)

1000

900~1100

3000

2800~3200

5000

4800~5200

4. Check the fuel gauge

(1) Disconnect the harness connector of fuel level sensor, ignition switch ON-position, check the

pointer of fuel gauge, normally at position E;

(2) Connect the connector terminals 2-F11 and 3-F11 at the side of fuel level sensor wire, ignition

switch ON-position, check the pointer of fuel gauge, normally at position F;

5. Check the fuel level warning lamp, disconnect the harness connector of fuel level sensor,

ignition switch ON-position, normally the pointer of fuel gauge should be at position E, fuel level

warning lamp lit.

6. Check the water thermometer

(1) Disconnect the harness connector of coolant temperature sensor, ignition switch ON-position,

check the pointer of water thermometer, normally at position C;

(2) Connect the connector terminal at the side of coolant temperature sensor wire to the body, and

check the pointer of water thermometer, normally at position H;

7. Check the seat belt reminder warning lamp

(1) Ignition switch ON-position, driver’s seat belt buckle open, check the seat belt reminder

warning lamp, normally lit;

(2) Ignition switch ON-position, driver’s seat belt buckle in, check the seat belt reminder warning

lamp, normally unlit;

(3) Disconnect the buckle switch connector, and connect the connector terminal at the side of

buckle switch wire to the body. Ignition switch ON-position, driver’s seat belt buckle in, check the

seat belt reminder warning lamp, normally lit;

8. Check the oil pressure warning lamp

Disconnect the harness connector of oil pressure warning lamp, ignition switch ON-position,

connect the connector terminal at the side of oil pressure warning lamp switch wire and the body,

normally, the warning lamp should be lit.

9. Check the oil pressure warning lamp switch

Disconnect the harness connector of oil pressure warning lamp, and check the conductivity

between the terminal of oil pressure warning lamp switch and the body. When the engine shuts

down, the wiring between terminal and body should be conducted; when the engine runs, the

wiring between terminal and body should be not conducted.

Loading...

Loading...