Page 5 of 182 TP1A002–1 English

Aug 2015

Linx 8900 Operating Manual —

Installation

Linx 8900

1.7 Product sensor setup

The Linx 8900 printer can use a product sensor to detect the presence of the product.

Normally, the message is printed when the printer receives a trigger signal from the

product sensor.

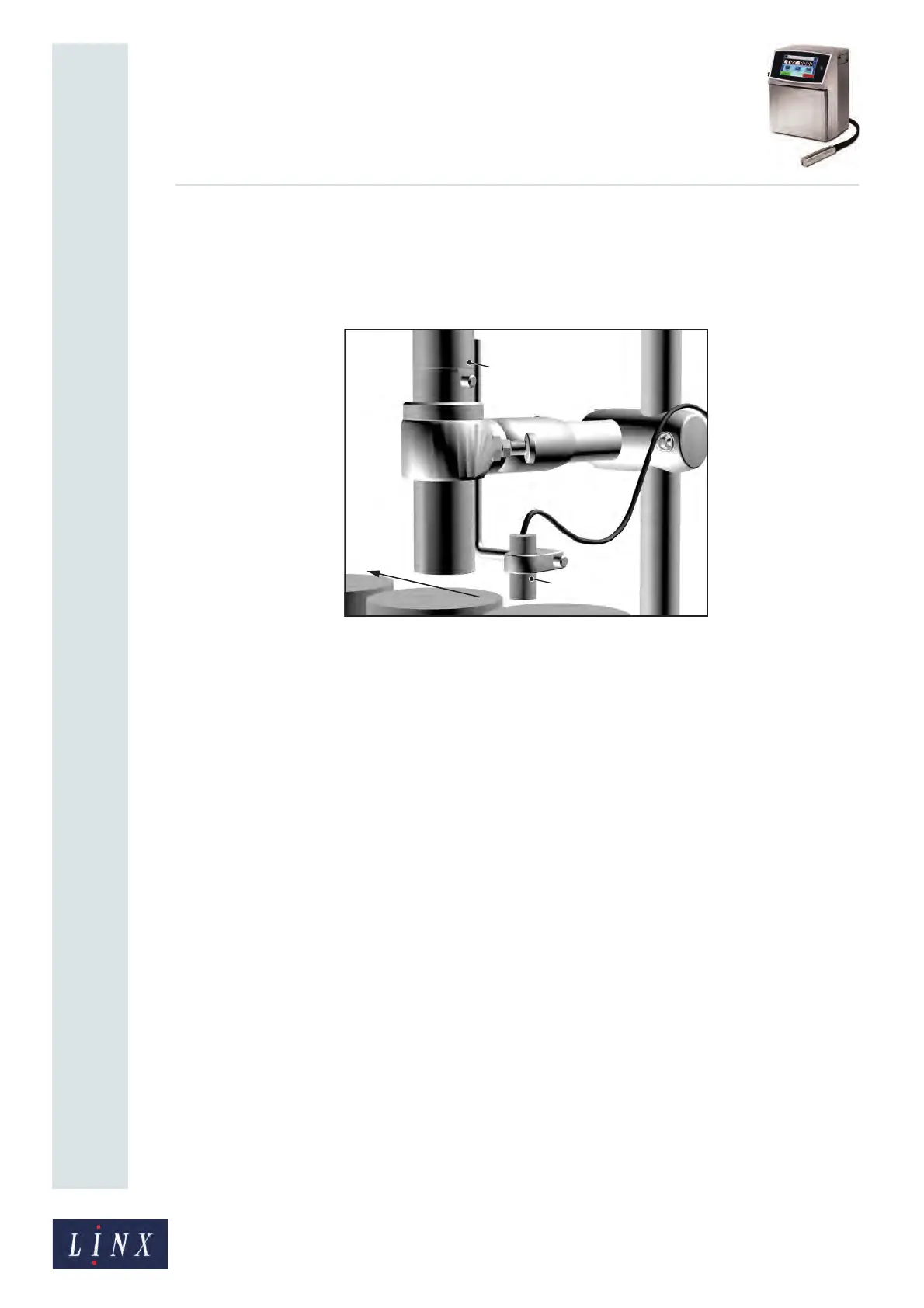

Figure 3. Product sensor setup

Normally, the product passes the product sensor first, then the printhead. The distance

between the printhead and the product sensor must be less than the distance between the

products.

Figure 3 shows the product sensor (A) and the printhead (B). The arrow shows the direction

of movement of the product along the production line.

The Print Delay parameter controls the distance between the product sensor and the

printed message. For information on how to adjust the Print Delay, see ‘Print Delay’ on

page 76.

The following product sensor types are available from Linx:

• Fibre optic control unit, 5 m D-type

• Retro-reflective light beam, 5 m D-type

• Inductive switch, 5 m D-type

• Reflection light beam scanner, 5 m D-type

• Background suppression sensor, 5 m D-type

• Colour registration mark scanner, 5 m D-type

Loading...

Loading...