Page 6 of 182 TP1A002–1 English

Aug 2015

Linx 8900 Operating Manual —

Installation

Linx 8900

1.7.1 Product sensor connection

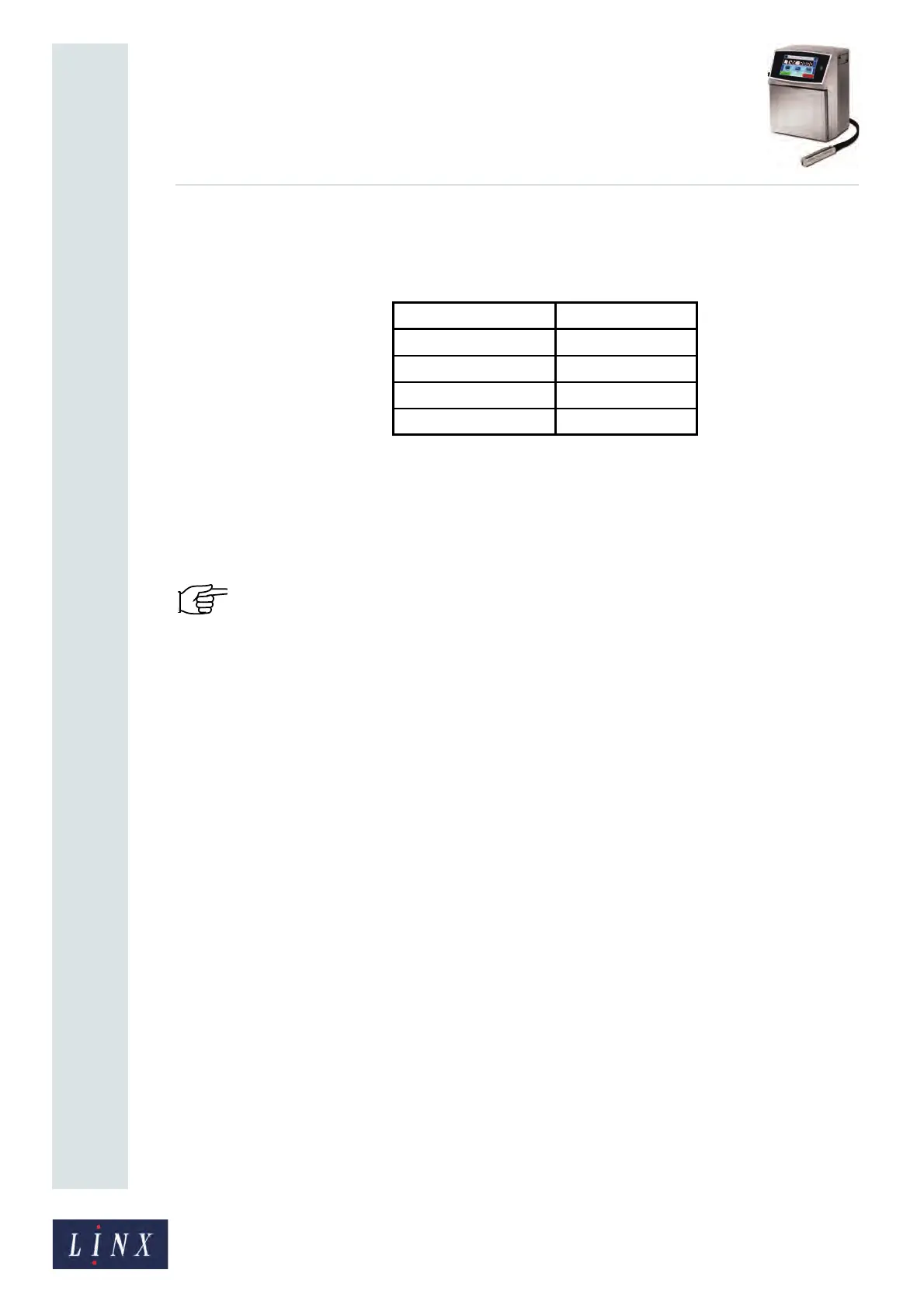

You must use a 9-pin, D-type connector to connect the product sensor to the printer. The

following table describes the function of each pin.

Connect the screen of the product sensor cable to the shell of the connector. The connector

shell must connect to the printer chassis. Do not connect the screen to 0 volts.

To maintain the IP55 rating of the printer, the connector of the product sensor must have at

the minimum an IP55 rating. Linx product sensors have a D-type connector that has an IP65

rating.

IMPORTANT: Use only Linx-approved accessories. The EMC performance of the printer

can change if you use other product sensors and cables.

1.7.2 Line speed detection setup

Linx recommends that you use a shaft encoder to detect the line speed on production lines

where the speed can change.

If your system has a fixed line speed, refer to ‘Fixed Speed’ on page 56 for information

about how to set the line speed.

The shaft encoder generates a pulse for a fixed distance of product movement. The pulses

enable the printer to print at a constant width if the line speed changes.

Normally the shaft encoder is attached to a drive shaft on the production line. Install the

shaft encoder in the best position to follow the movement of the products.

Linx offers the following range of shaft encoders for line speed detection:

• 2500 pulses per revolution (ppr)

• 5000 ppr

• 10000 ppr

Each shaft encoder has a 5-metre cable fitted with a 9-pin, D-type connector.

To measure the line speed, you can connect the shaft encoder to a drive shaft on the line, or

to an encoder wheel. Linx provides the following range of encoder wheels:

• 500 mm circumference

• 333 mm circumference

• 304.8 mm (1 foot) circumference

• 200 mm circumference

• 60 mm circumference

Function Pin number

+ 24 V 1

0 V 2

Secondary trigger 4

Primary trigger 6

Table 1-2. Product sensor pin connections

Loading...

Loading...