Page 7 of 182 TP1A002–1 English

Aug 2015

Linx 8900 Operating Manual —

Installation

Linx 8900

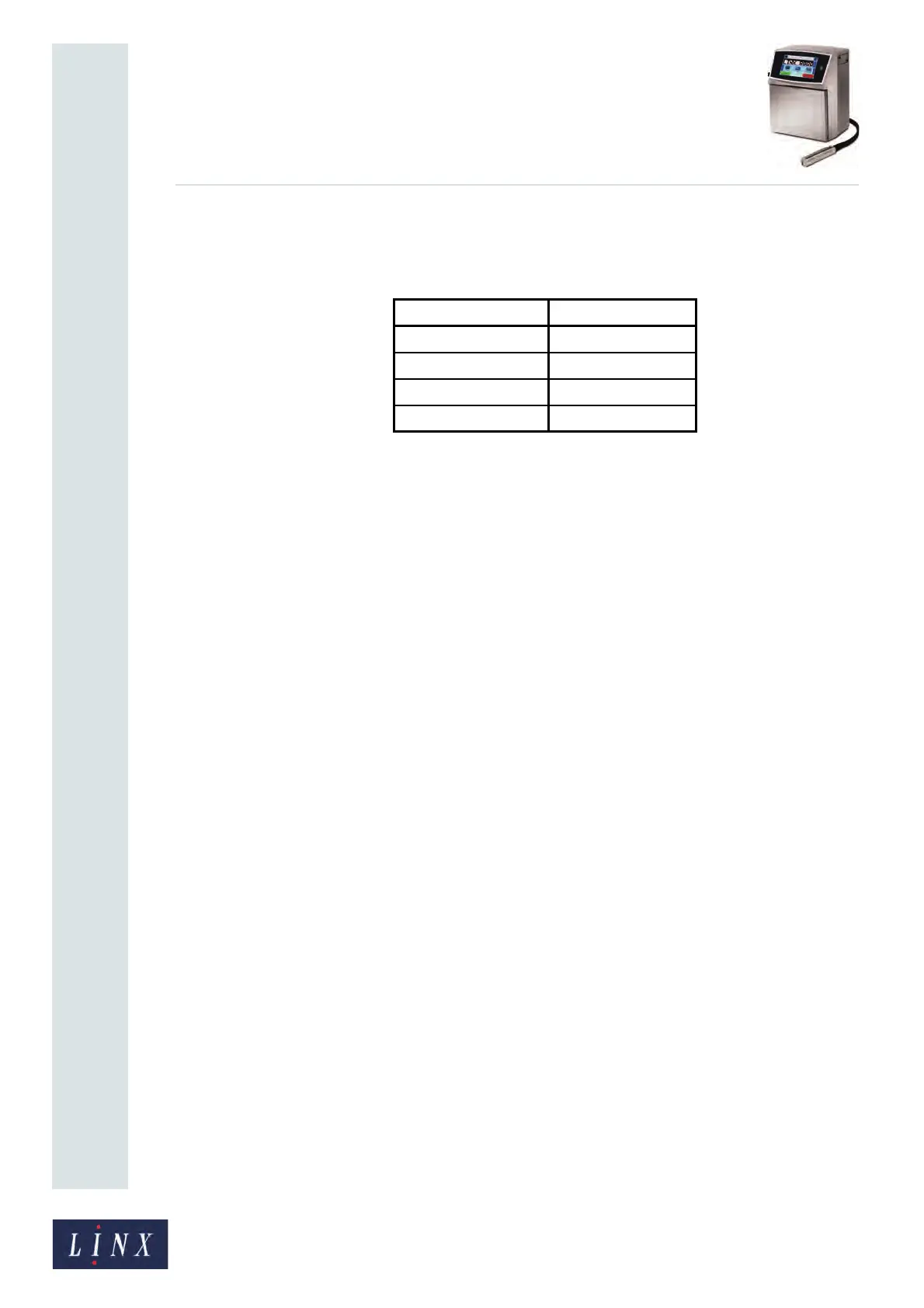

Shaft encoder connection

You must use a 9-pin, D-type connector to connect the shaft encoder to the printer. The

following table describes the function of each pin.

Connect the screen of the shaft encoder cable to the shell of the connector. The connector

shell must connect to the printer chassis. Do not connect the screen to 0 volts.

To maintain the IP55 rating of the printer, the connector of the shaft encoder must have at

the minimum an IP55 rating. Linx shaft encoders have a D-type connector that has an IP65

rating.

CAUTION: Use only Linx-approved accessories. The EMC performance of the printer

can change if you use other shaft encoders and cables.

Calculate the encoder pitch

If you use a shaft encoder, the printer can calculate the encoder pitch for you. Refer to

‘Calculate Line Speed/Calculate Encoder Pitch’ on page 58 for more information about how

to calculate the encoder pitch.

Check the print samples for performance. If necessary, you can use the Print Width option

to make small adjustments to the horizontal distance between ink drops in a message

character. Refer to ‘Print Width’ on page 80 for more information.

If you do not follow the calculation, your messages are not printed at the required size. The

spaces between the ink drops in a message are too small or too large.

Function Connection pin

+ 24 V Pin 1

0 V Pin 2

+ 5 V Pin 3

Single-ended input Pin 8

Table 1-3. Shaft encoder pin connections

Loading...

Loading...