INTRODUCTION 2250 SERVICE/MAINTENANCE MANUAL

1-96

Published 07-19-16, Control # 249-01

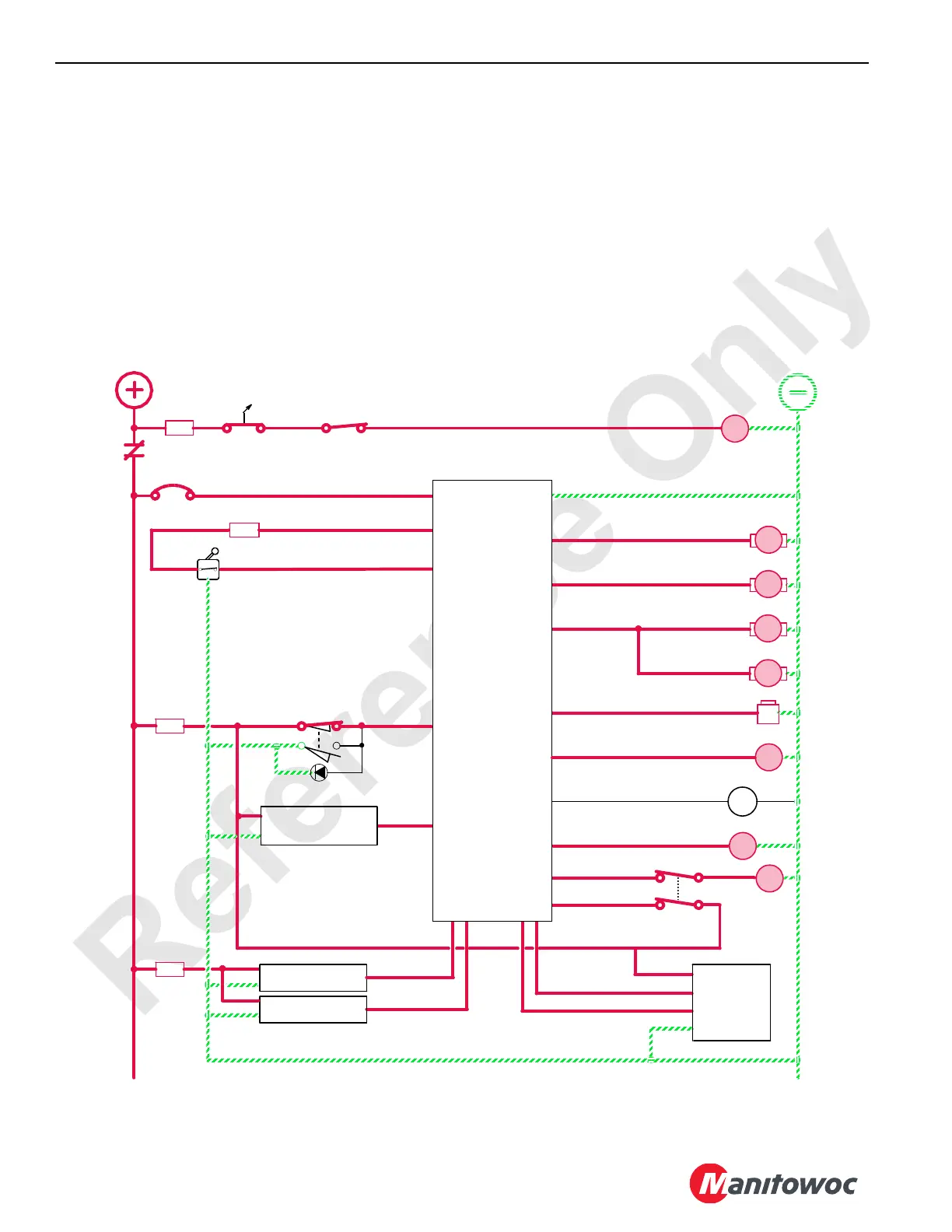

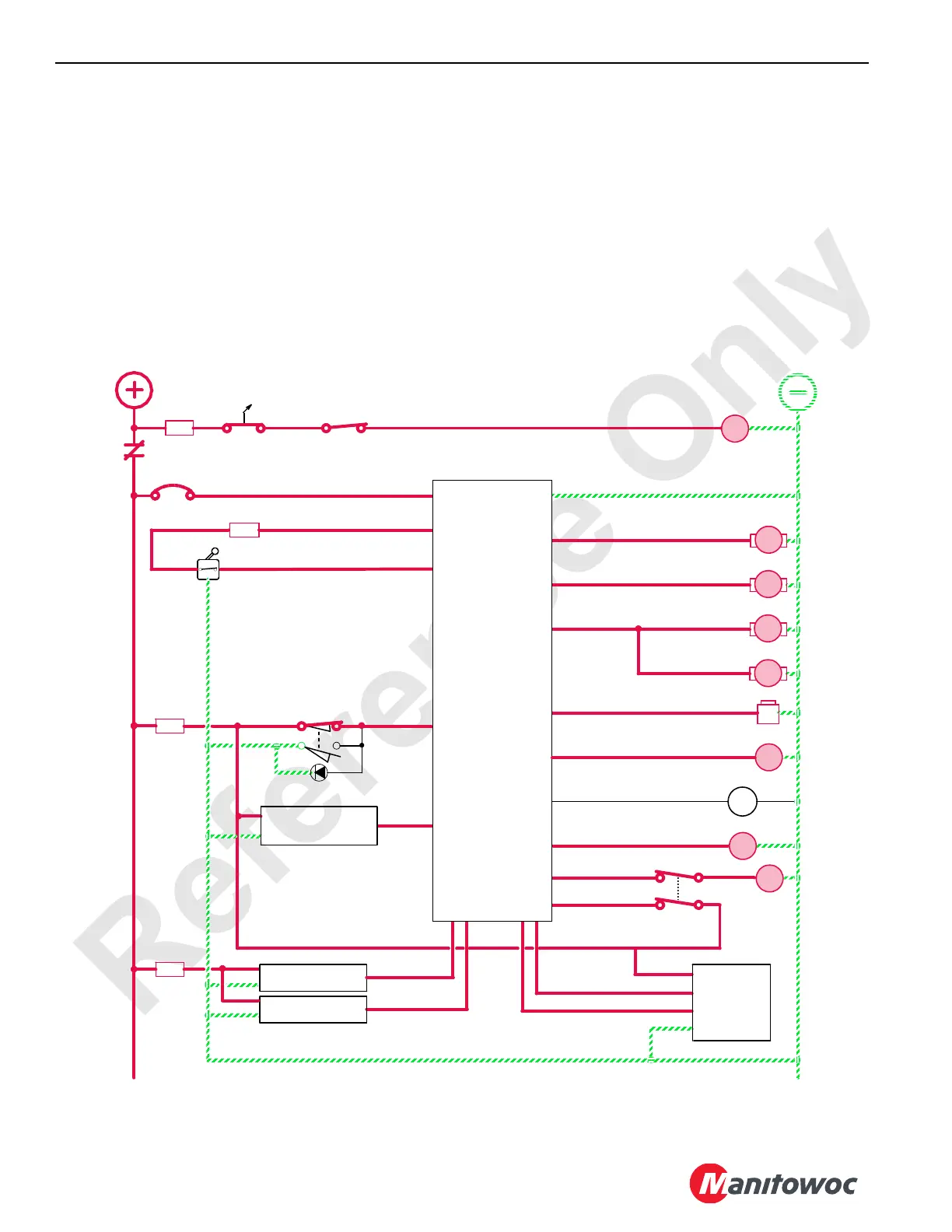

The crane’s PC controls raising speed by varying the voltage

to both pumps’ EDC and motor’s PCP in relation to the

handle’s movement. As the handle is moved back (RAISE),

the crane’s PC sends a signal to increase the pump’s

swashplate angle. The crane’s PC also sends a signal to the

motor’s servo to reduce the motor’s displacement. The

crane’s PC is continuously balancing the system pressure

and the motor’s displacement angle so the motor’s

displacement goes to minimum when the handle is all the

way back, if torque requirement on the motors is not too high.

Knowing the displacement of the motors, the crane’s PC may

then control the speed that the motors turn by regulating the

flow through the pumps.

When the left control handle is moved to the neutral position,

the crane’s PC sends an output signal to the travel pump’s

EDCs to decrease the swashplate angle, reducing oil flow

output. This shifts the motor’s servos back to maximum

displacement for slower output speed to slow the drum’s

rotation. The crane’s PC stores the load-holding pressure in

pressure memory. After the control handle’s neutral switch

opens, the PC sends an output signal to disable the brake

solenoid HS-56 to apply the brake before the travel pumps

de-stroke.

Left Handle Control

Left Travel

Sender

Right Travel

Sender

LOWERRAISE

Regulated 10V Out

5A

OFF

3A

8T

88MC

RM19

Drum 9

Flange

Encoder

80N

A

B

A

B

Drum 9 Left

Motor Control

Drum 9 Right

Motor Control

84A

83A

Right Travel

Pump Control

Left Travel

Pump Control

A

B

B

A

Left Control

Rotation Indicator

88D

Travel/Drum 9

Diverting Valve

AS

Drum 9

Brake

Pawl In

Pawl Out

88C

88CA

88E

88N

83DS

8K

84DS

87FA

80P

5DA

5A

Cab Power

OFF

ON

D

B

A

F

8P1

0

K1

50 Amp

0

10A

5D

5A

88MB

Drum 9

Minimum

Bail Limit

88MA

Engine

RUN/STOP

89G4

EDC

PCP

PCP

EDC

HS

54

HS

56

AS

22

21

Drum 9

Drum 9

K1

Crane

Programmable

Controller

FIGURE 1-63

90QM

Mast

Accumulator

Sender

F15

F12

Loading...

Loading...