BOOM 2250 SERVICE/MAINTENANCE MANUAL

4-16

Published 07-19-16, Control # 249-01

STRAP INSPECTION AND MAINTENANCE

This is a guide for properly inspecting and maintaining straps

in the field. It is impossible to predict whether or when a strap

may fail. Frequent inspections can help reveal potential for

failure. A qualified person should inspect straps regularly

and keep dated records as part of the crane’s preventive

maintenance program.

Strap repairs are prohibited. Perform only the maintenance

indicated. For inspection procedures not covered in this

service manual, contact your dealer or the Manitowoc Crane

Care Lattice Team.

Strap connecting links are subject to the same inspection

procedures and replacement specifications as those for the

straps. The word “strap” means the strap and its connecting

links.

Inspection

A routine inspection of all straps is necessary to ensure that

the crane can lift its rated load. If a strap fails, the boom or

other attachment can collapse. A qualified, appointed

inspector shall perform all inspections at the following

intervals:

• Routinely—daily (frequent inspection) or monthly

(periodic inspection)

• Before initial use

• After transport

• After an overload or shock loading has occurred

• If the boom or jib has come into contact with another

object such as power lines, a building, or another crane

• If the boom or jib has been struck by lightning

Frequent Inspection

Visually inspect all straps once each shift for obvious

damage that poses an immediate hazard. Pay particular

attention to areas where wear and other damage is likely to

occur. Look for straps that are disconnected, loose, or

sagging excessively and for distortion, such as kinking or

twisting. If a strap looks like it is damaged, it must be

checked to make sure it is within specification.

Periodic Inspection

Periodic inspection must be performed at least monthly.

During this inspection, the entire length of strap must be

inspected to ensure that it is within specifications.

NOTE: All straps must be within specification. Any damage

found must be recorded and a determination made

as to whether continued use of the strap is safe.

Before beginning an inspection, thoroughly clean the strap of

all dirt, grease, and oil so a thorough inspection can be

made. Examine areas where paint is chipped, wrinkled, or

missing and where faint rust lines or marks appear.

A qualified inspector may modify the interval for periodic

inspection depending on the following factors:

• The severity of the environment in which the crane is

operated

• The size, nature, and frequency of lifts

• Any exposure to shock loading or other abuse

Inspecting the Straps on Idle Cranes

A qualified inspector should determine the type of inspection

required for cranes that are not being used (idle). A frequent

inspection (visual observation) should be adequate for a

crane that has been idle for less than six months. A periodic

inspection is required for cranes that have been idle for more

than six months.

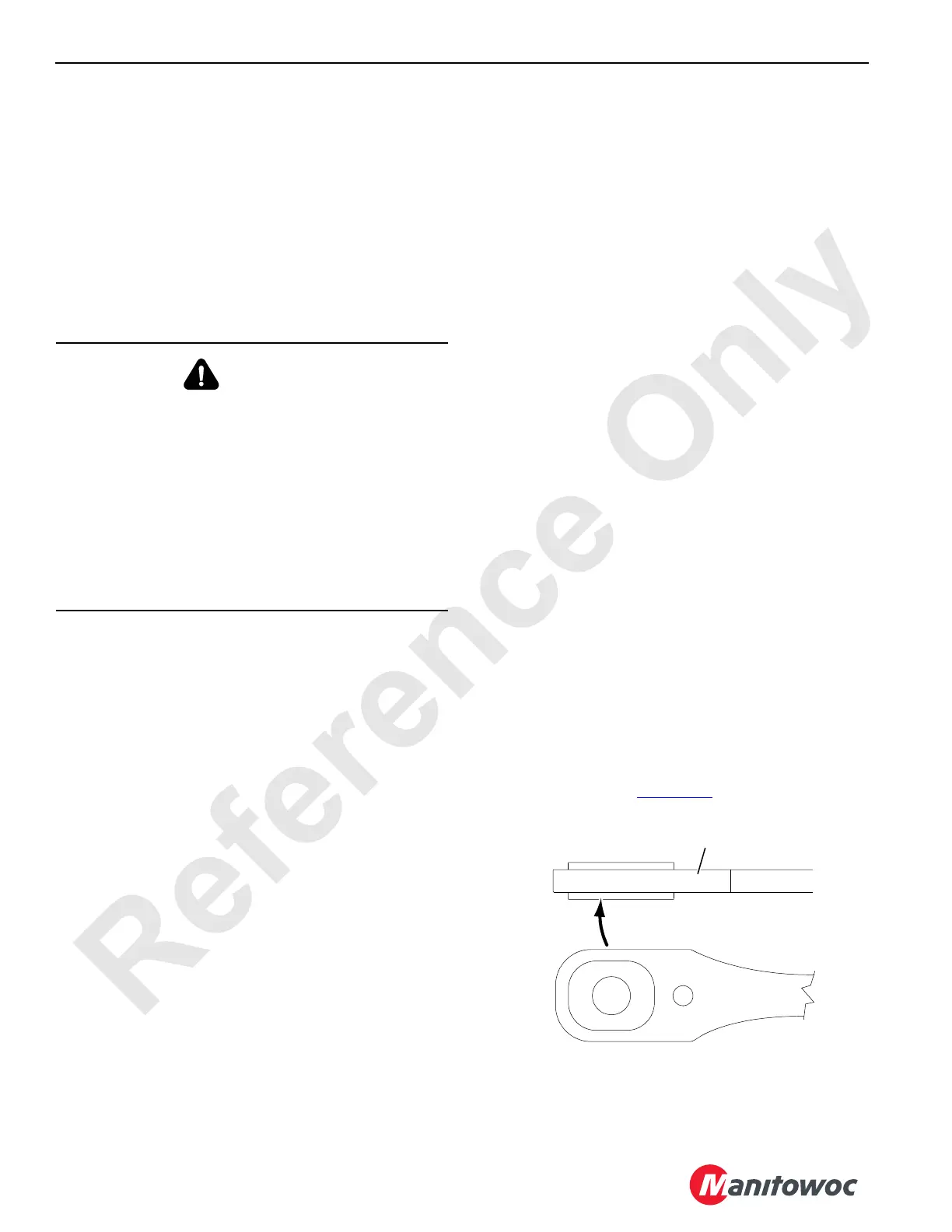

Identifying Straps

To aid in strap identification, a part number is stamped into

both ends of each strap (Figure 4-11

).

WARNING

Falling Attachment Hazard!

Operating the crane with a damaged strap can cause

structural failure or collapse of the boom, jib, mast, or

other crane components, which can cause death or

serious injury.

If damage to a strap was caused by an overload or a

shock load, or if there is damage to other major structural

components, Manitowoc Cranes recommends that a

thorough inspection be made by a qualified person. A

nondestructive test of all critically stressed members must

be made.

XXXXXX

Part Number

A1012

FIGURE 4-11

Loading...

Loading...