HYDRAULIC AND AIR SYSTEMS 2250 SERVICE/MAINTENANCE MANUAL

2-38

Published 07-19-16, Control # 249-01

SHUTTLE VALVE MAINTENANCE

General

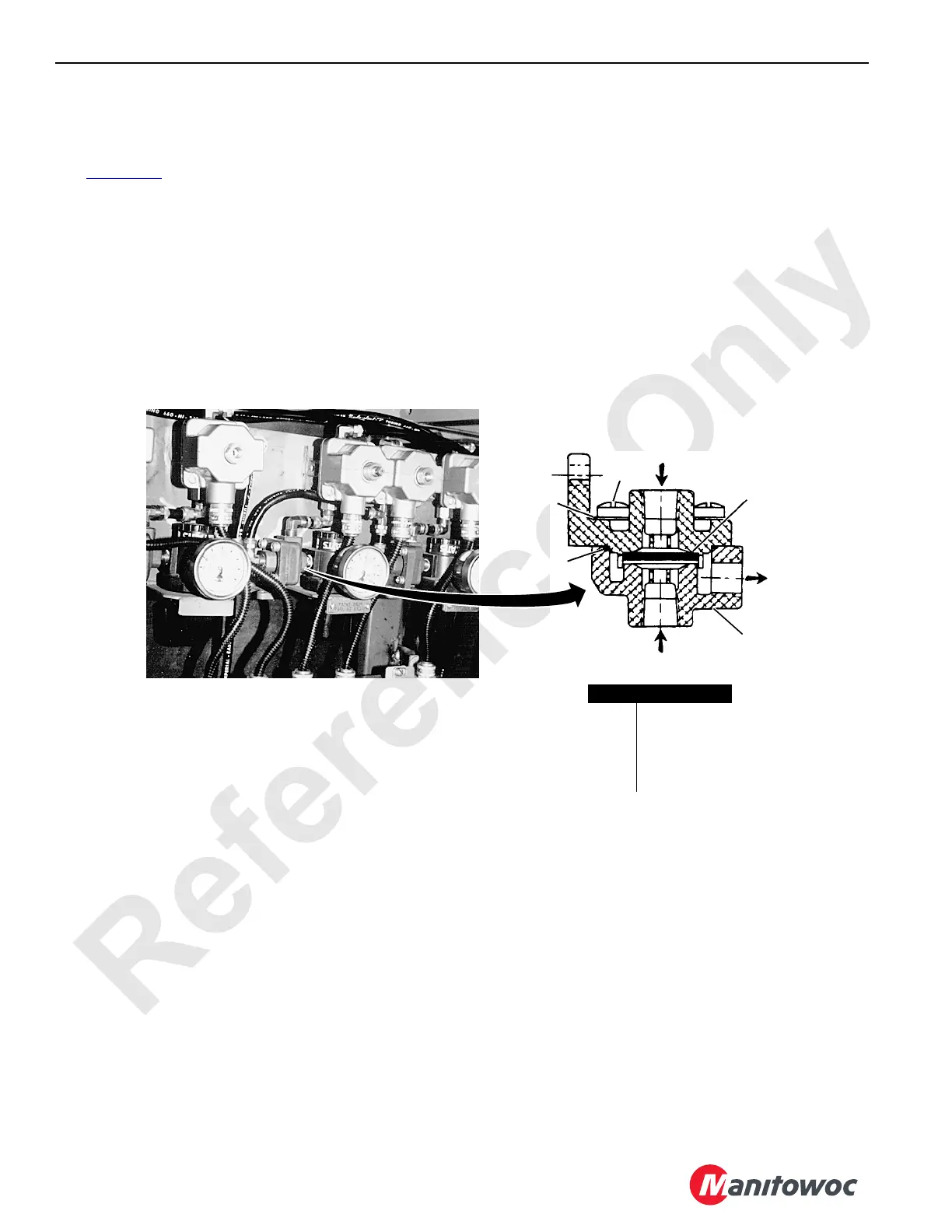

See Figure 2-42 for the following.

The shuttle valve automatically selects the higher pressure

from one or the other of two controlling devices and directs

the flow of air to a common outlet. The valve serves to

connect two segregated lines to a common line without

destroying the segregation.

Operation

The shuttle valve has three ports. When a pressure

differential of 0.07 bar (1 psi) or more exists between either

IN port, the higher pressure forces the diaphragm to seal the

opposite port of the valve and air flows out the common OUT

port. The low pressure IN port is sealed from both the OUT

port and the opposite side IN port.

Maintenance

By removing the screws (1) and washers (2), the body (3)

can be removed for easy replacement of the diaphragm (4)

without disturbing the piping connections.

When complete disassembly is required, wash all metal

parts with a nonflammable solvent. Wash all rubber parts

with soap and water. Rinse thoroughly and blow dry with a

low-pressure air jet. Replace the diaphragm and gasket (5) if

they are damaged or worn. Reassemble the valve and check

for leaks during operation. No lubricant is required.

S117

1

P310

FIGURE 2-42

In

4

Out

In

5

2

3

Item Description

1 Screw (qty 4)

2 Washer (qty 4)

3Body

4 Diaphragm

5 Gasket

Loading...

Loading...