HOISTS 2250 SERVICE/MAINTENANCE MANUAL

5-8

Published 07-19-16, Control # 249-01

INSPECTING AND ADJUSTING THE DRUM

BRAKE

Description

Each drum brake consists of an external, contracting band-

type brake and two actuators. On single drum shafts, the

brake is mounted on the left end of the drum. On split drum

shafts, a brake is mounted on the outboard end of both

drums. An independent drum drive has two brakes, one

mounted on the left end of the drum shaft and the other

mounted on the right end.

Each actuator has two chambers that provide two separate

braking systems for each load drum as follows:

• The spring chamber provides a spring-applied, air-

released park brake. In the full power mode, the load

drum control automatically applies and releases the park

brake.

• Only one service chamber is used. It provides an air-

applied, spring-released working brake. Braking control

is variable, from fully applied to fully released, through

the use of a treadle valve.

The operator must be seated and the engine must be

running to operate the drum controls and park brakes during

inspection, adjustment, and overhaul procedures. The

drums are automatically parked and the handles are

inoperable when the operator is out of the seat or the engine

is off.

Inspecting and Adjusting the Brake

1. Inspect all pins and linkage for excessive wear. Replace

parts as required. Worn pins and linkage make it difficult

to obtain the proper drum-to-lining clearance.

2. Lubricate the pins in the linkage with a few drops of

engine oil. Lubricate the grease fittings. See Lubrication

Section 9 for more information.

3. Check the linings for excessive wear. Linings normally

wear faster at the dead end of the brake band. Check

this area first.

The brake lining is 12 mm (1/2 in) thick when new.

Replace the lining when the thinnest area has worn to

5mm (7/32in) thick.

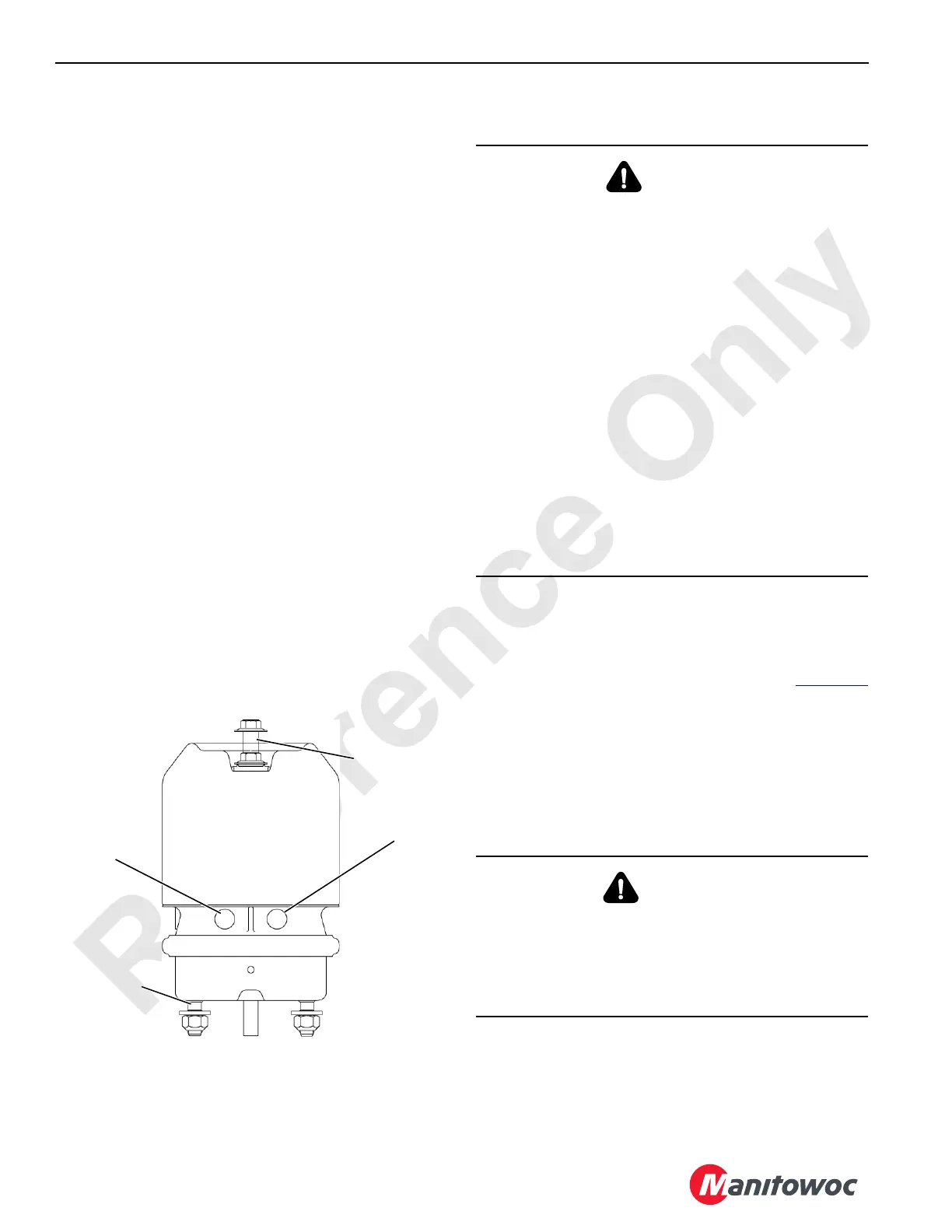

Mounting Studs

FIGURE 5-6

Service Brake Port

(working brake)

192789-2

Service Brake Port

(park brake)

Brake Release

(shown caged)

CAUTION

Moving Machinery Hazard!

It is necessary to rotate the load drum and apply and

release the drum park brake during inspection,

adjustment, and overhaul procedures. This creates a

condition in which, if care is not exercised, minor injury or

equipment damage may occur.

Drum brake inspection, adjustment, and overhaul

requires two people—one to operate the drum and brake

controls and one to perform the inspection, adjustment,

and overhaul procedures. Maintain constant

communication between the adjuster and operator so the

drum and brake are not operated while the adjuster is in

contact with moving parts.

Lower the load block or weight ball onto the ground so the

wire rope is slack on the drum being serviced.

• The adjuster shall stay clear of all moving parts while

the drum and brake are being operated.

• The operator shall not operate the drum or brake

controls until the adjuster is clear of moving parts.

WARNING

Falling Load Hazard!

Aftermarket brake linings may not provide the proper

brake torque. The brake could slip, allowing the load to

drop, resulting in death or serious injury.

Only use Manitowoc Cranes original equipment linings.

Loading...

Loading...