Manitowoc Published 07-19-16, Control # 249-01 2-3

2250 SERVICE/MAINTENANCE MANUAL HYDRAULIC AND AIR SYSTEMS

• Replace tubes that are cracked, kinked, or bent.

• Replace hoses that are cracked, split, or abraded.

• Listen to pumps and motors for unusual noises. A high-

pitched whine or scream can indicate that air is being

drawn in.

An air leak can be pinpointed by flooding the inlet fitting,

hose, or tube with oil. If there is an air leak, the oil will

cause a noticeable reduction in noise. Correct the cause

of any air leak, or the pump/motor will be damaged.

A high-pitched whine or scream from the pump can also

indicate cavitation (pump being starved of oil). This

condition is caused by the following problems:

• Plugged suction filter

• Collapsed or plugged suction line

• Wrong oil (viscosity too high)

NOTE: Do not return leakage oil back to the hydraulic tank.

• Inspect for signs of overheating, such as heat-peeled

parts, a burned or scorched oil odor, and darkening and

thickening of oil. The maximum temperature of the oil in

the tank must not exceed 82°C (180°F).

• Have the hydraulic oil analyzed at regular intervals to

determine the condition of oil and the extent of system

contamination.

By having the oil analyzed on a regular basis, an oil

change interval that meets your operating conditions

can be established.

NOTE: Contact your oil supplier for the availability of oil

analysis services and the steps that should be

taken to obtain these services.

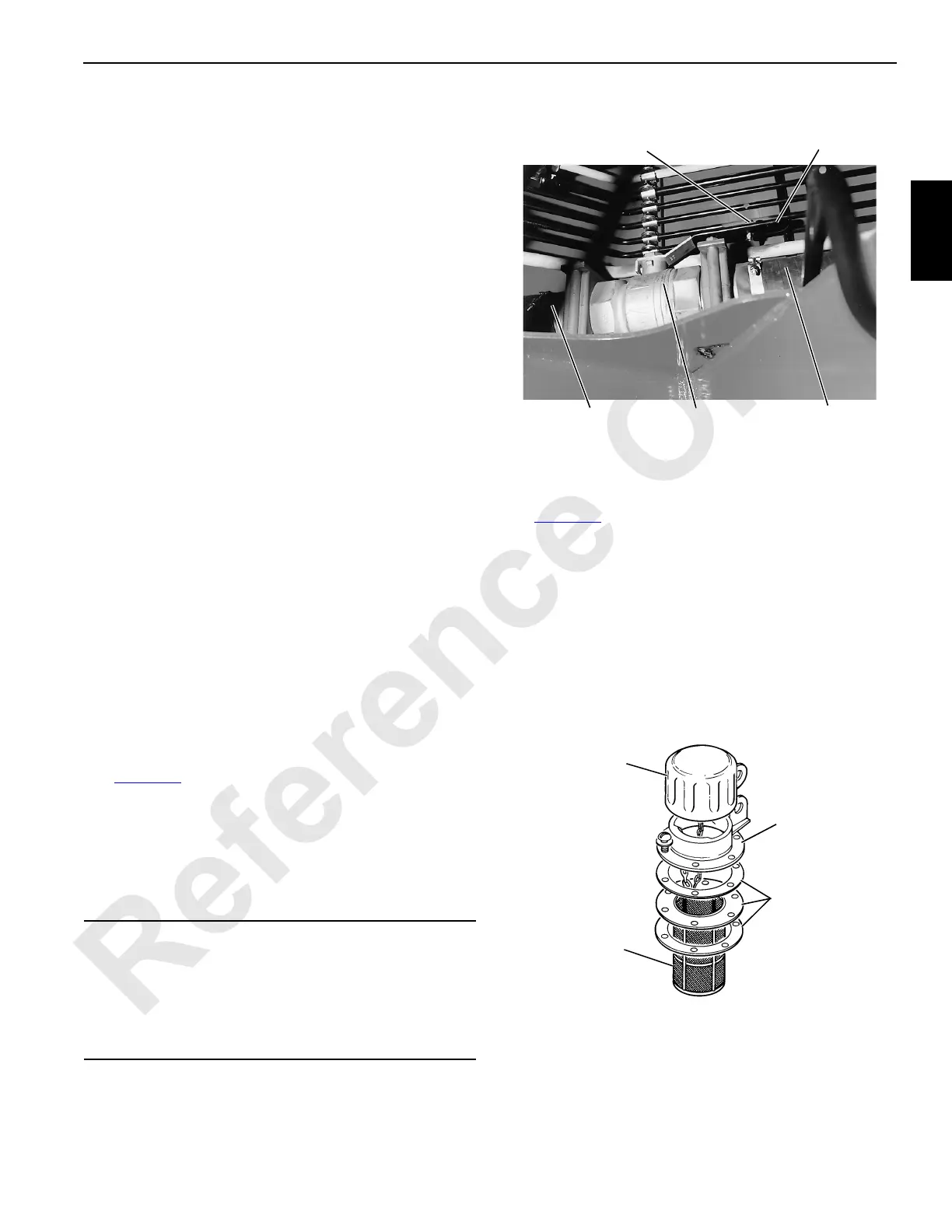

Servicing the Pumps

See Figure 2-1 for the following.

It is not necessary to drain the hydraulic tank when servicing

the hydraulic pumps. To service the pumps, close the

hydraulic tank shut-off valve in the pump suction line.

After servicing the pumps, open the valve prior to starting the

engine. The valve can be locked open with a padlock.

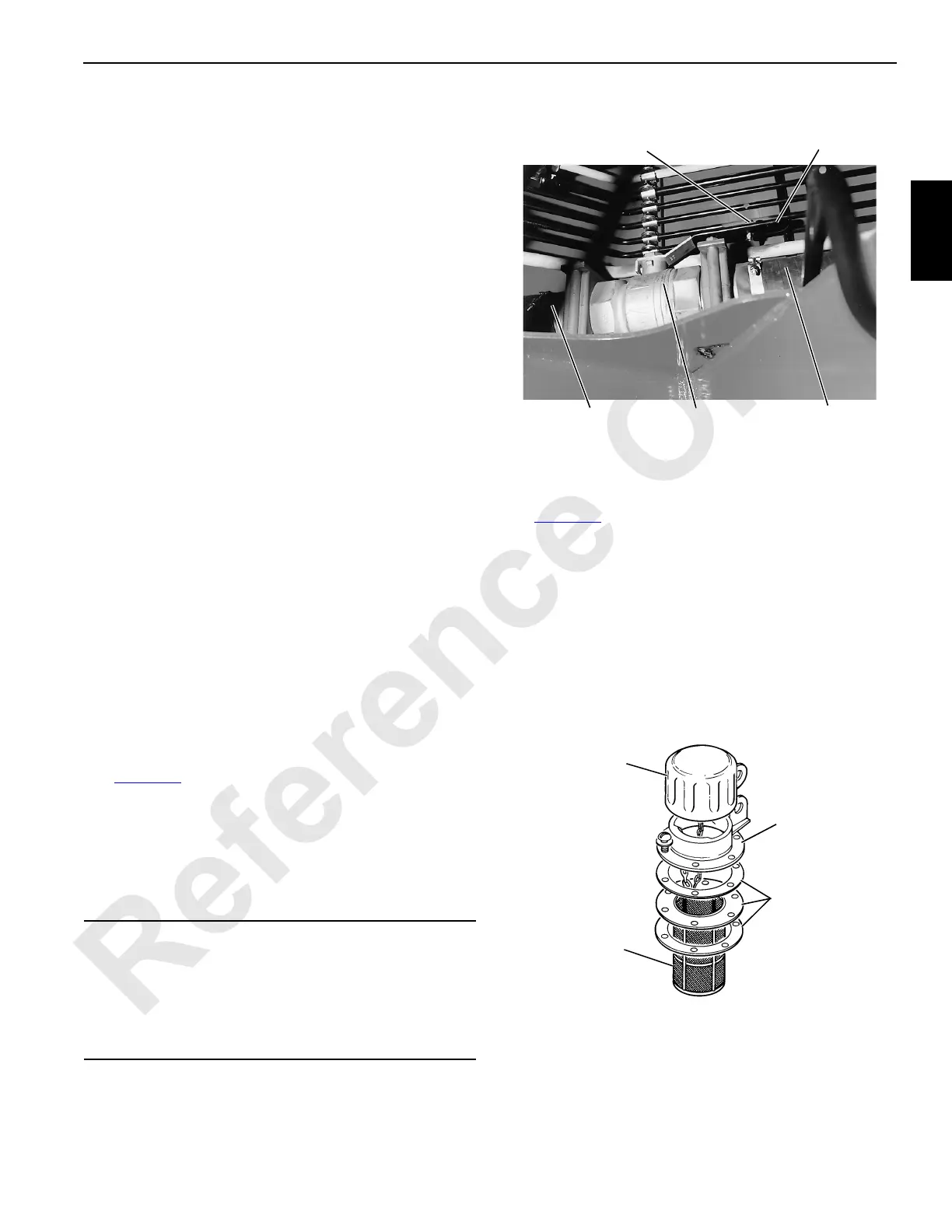

Cleaning the Fill Cap Assembly

See Figure 2-2 for the following procedure.

1. Clean the fill cap weekly to ensure that the ventilating

ports in the fill cap remain open.

a. Clean the area around the fill cap.

b. Remove the fill cap from the flange.

c. Thoroughly clean the fill cap with a clean,

nonflammable solvent. Blow dry the fill cap with

compressed air.

d. Reattach the fill cap to the flange.

2. Clean the entire fill cap assembly whenever the

hydraulic oil is changed.

a. Clean the area around the fill cap.

b. Disassemble the fill cap.

CAUTION

Hydraulic Pump Damage!

Running the hydraulic pumps without an adequate oil

supply will result in damage to the pumps from cavitation.

Open the hydraulic tank shut-off valve before starting the

engine.

FIGURE 2-1

P779

Hydraulic Tank

Shut-Off Valve

To Hydraulic

Tank

Handle Open

(pull toward you to close)

To

Pumps

Install Bolt and Nut or Padlock

to Lock Handle Open

FIGURE 2-2

S100

Fill Cap

Screen

Flange

Gaskets

Loading...

Loading...