Manitowoc Published 07-19-16, Control # 249-01 8-3

2250 SERVICE/MAINTENANCE MANUAL UNDERCARRIAGE

Adjusting the Tread Slack

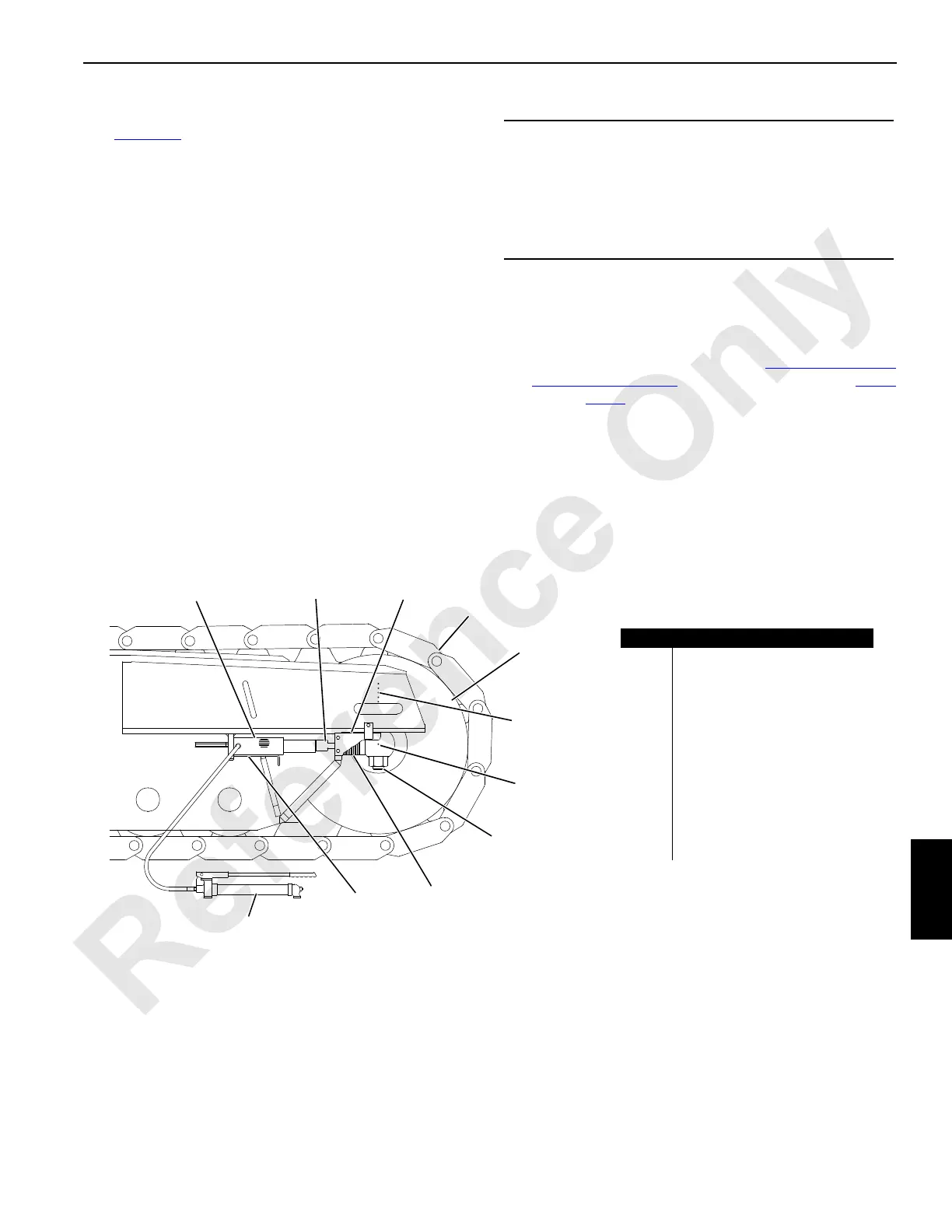

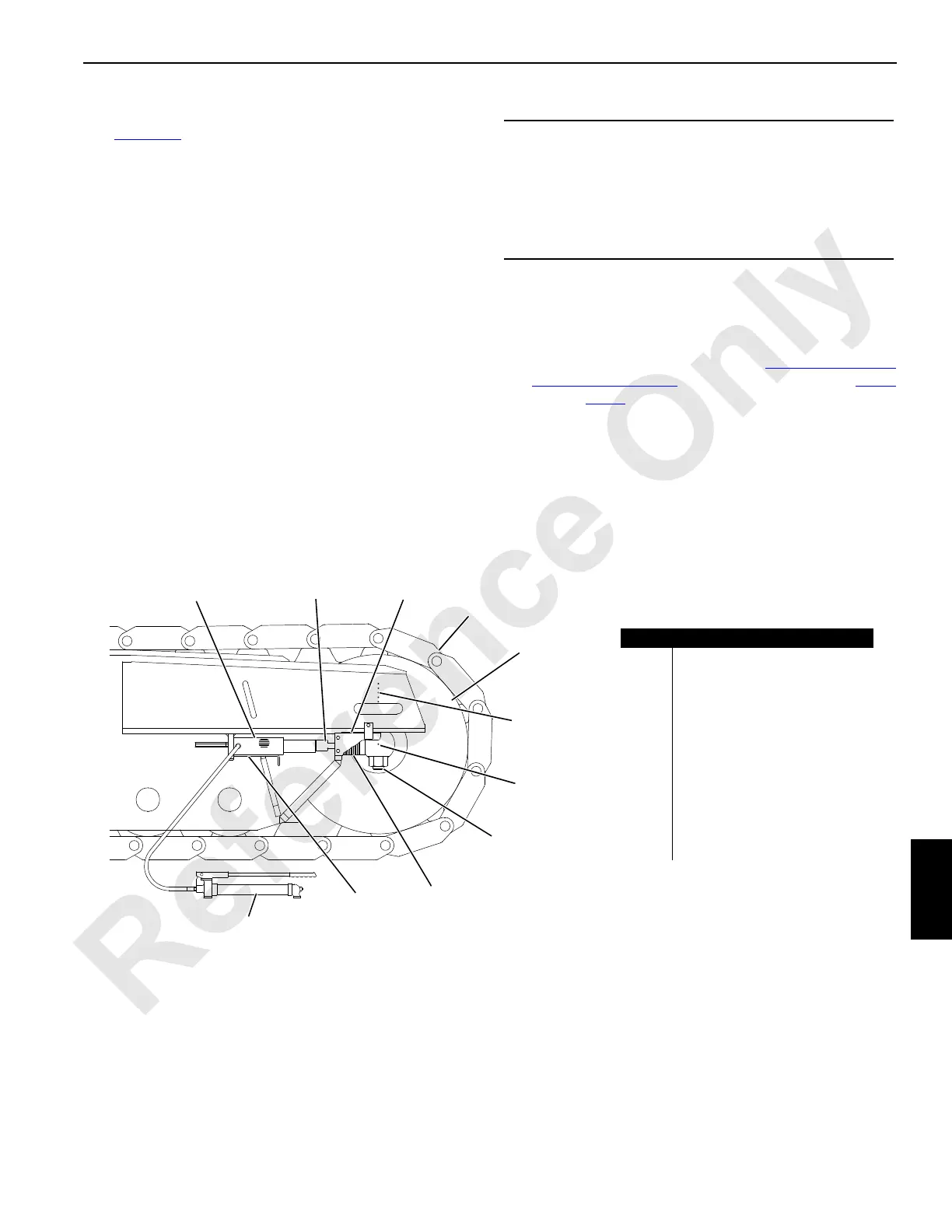

See Figure 8-3 for the following procedure.

Adjust the tread slack at the front roller end of each crawler.

1. Thoroughly clean the crawler to be adjusted.

2. Loosen the two bolts (1) at the front roller end of the

crawler (1 bolt, each side).

3. Remove the cover (2) from each side of the crawler

frame.

4. Place the jack cylinder (3) on the support (4).

5. Using the hand pump (11), jack against the rod (5) an

equal amount on both sides of the crawler frame.

6. Add or remove an equal thickness of shims (6) on both

sides of the crawler frame.

7. Remove the jack cylinder.

8. Travel the crane forward to tighten the shims.

9. Verify that the dimension from center punch mark A (10)

in the shaft to center punch line B (9) in the crawler

frame is within 3 mm (1/8 in) of each other on both sides

of the crawler.

10. Check for proper adjustment (see Crawler Adjustment

Guideline on page 8-2) and readjust as required (step 4

through step 9).

11. Tighten the nuts on the bolts at the front roller to

2 712 Nm (2,000 lb-ft).

12. Install the cover on each side of the crawler frame.

NOTE: The extreme limit of crawler tread (7) adjustment is

when the bolts are tight against the front end of the

slots in the crawler frame. One crawler tread can

be removed when this limit is reached.

CAUTION

Excessive Part Wear!

Crawler parts will wear rapidly if they are not adjusted

properly.

Make sure the front roller (8) and the rear tumbler are

square with the crawler frame to within 3 mm (1/8 in).

FIGURE 8-3

Item Description

1 Bolt (qty 2)

2 Cover (qty 2)

3 Jack Cylinder

4 Support (qty 2)

5 Rod (qty 2)

6Shims—

3 mm (0.12 in) and

6 mm (0.25 in) Thick (

qty varies)

7 Crawler Tread

8 Front Roller

9 Center Punch Line B

10 Center Punch Mark A

11 Hand Pump

A1052

11

10

9

5

6

7

8

1

2

3

4

Loading...

Loading...