INTRODUCTION 2250 SERVICE/MAINTENANCE MANUAL

1-92

Published 07-19-16, Control # 249-01

Mast Stop

Mast Stop Cylinders

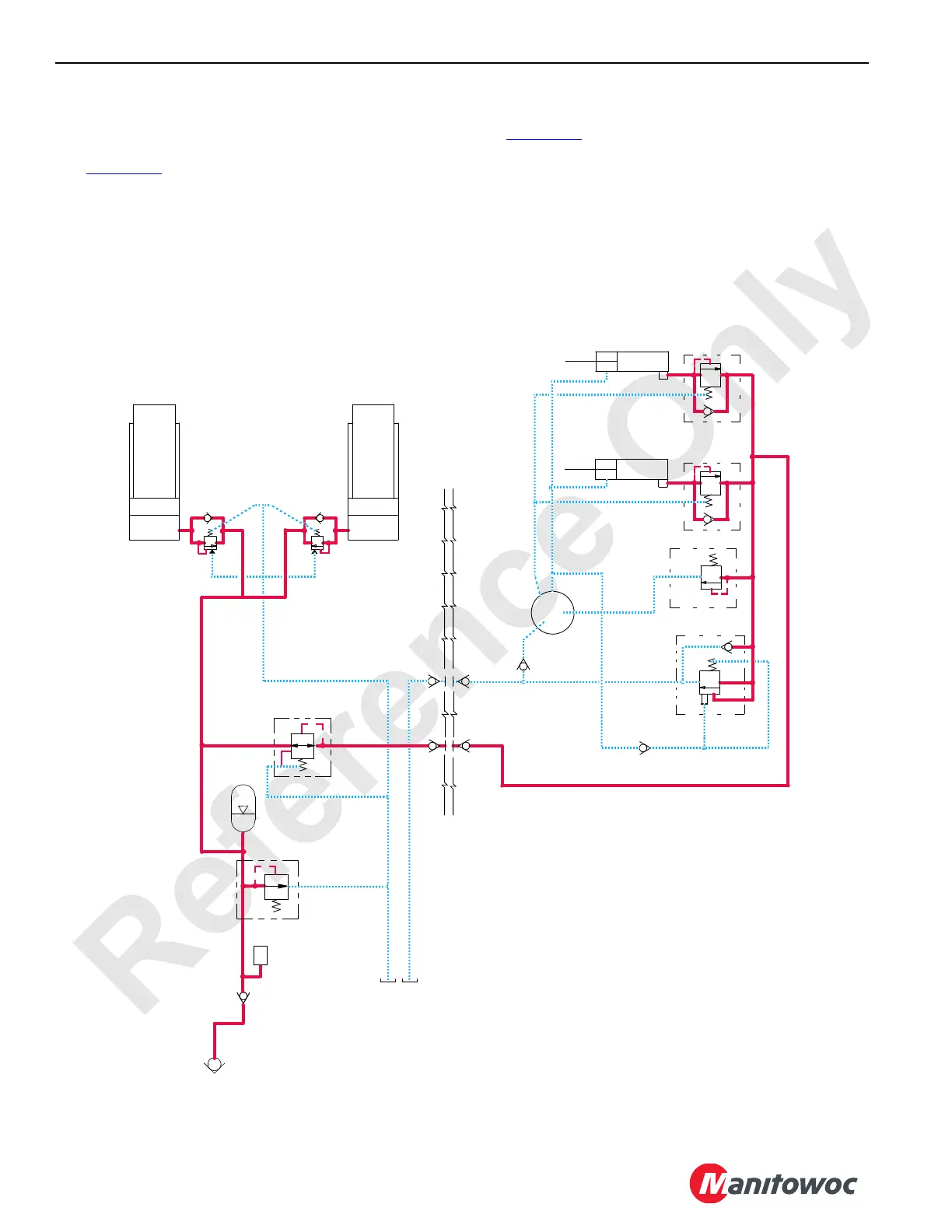

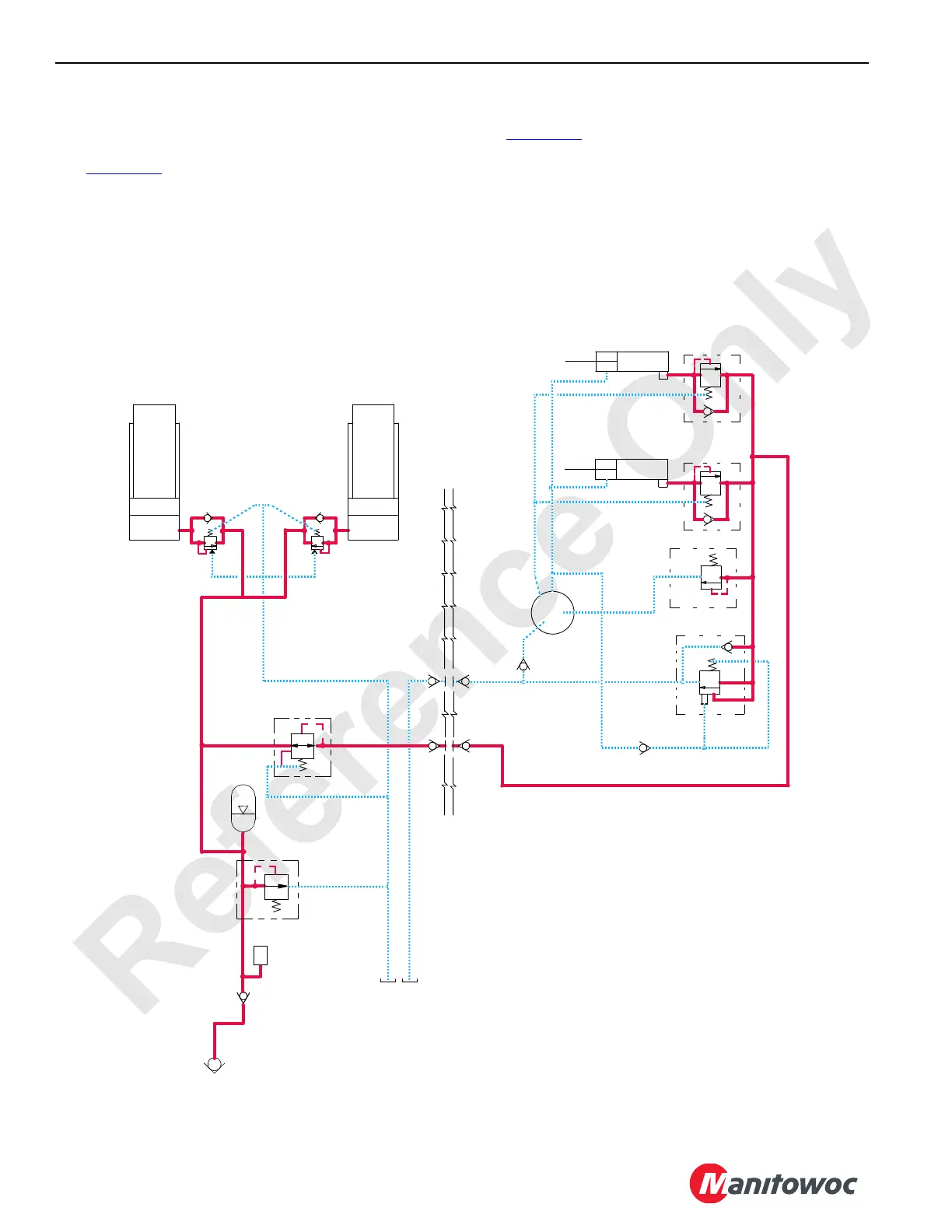

See Figure 1-60 for the following.

The mast stop cylinders are connected to the mast and

contact the gantry pins to stop the mast when at or near

maximum mast angle. The hydraulically filled cylinders act

as shock absorbers to cushion the mast as it contacts the

gantry. After a certain distance, the mast stop cylinders

bottom out to stop the mast’s travel.

Mast Stop System Operation

See Figure 1-60 for the following.

The crane’s auxiliary pump supplies pressurized hydraulic

fluid to the mast stop cylinders and jib strut cylinders at

152 to 200 bar (2,200 to 2,900 psi). The system pressure is

monitored and controlled by the mast accumulator pressure

sensor. From the crane’s auxiliary pump, pressurized

hydraulic fluid goes through the quick disconnect at the mast

butt, through an in-line check valve, and into an accumulator

mounted on the mast butt.

RM-16

179 bar (2,600 psi)

(2,400 psi)

Mast Stop

Cylinders

Jib Strut

Reservoir

Jib Strut

145 bar (2,100 psi)

145 bar (2,100 psi)

Relief Valve

Relief Valve

Cylinders

FIGURE 1-60

Boom

Mast

(2,200 psi)

Accumulator

T

Pressure

Sender

Accumulator

Mast

166 bar

207 bar (3,000 psi)

152 bar

Loading...

Loading...