Manitowoc Published 07-19-16, Control # 249-01 2-33

2250 SERVICE/MAINTENANCE MANUAL HYDRAULIC AND AIR SYSTEMS

Maintenance

Troubleshooting

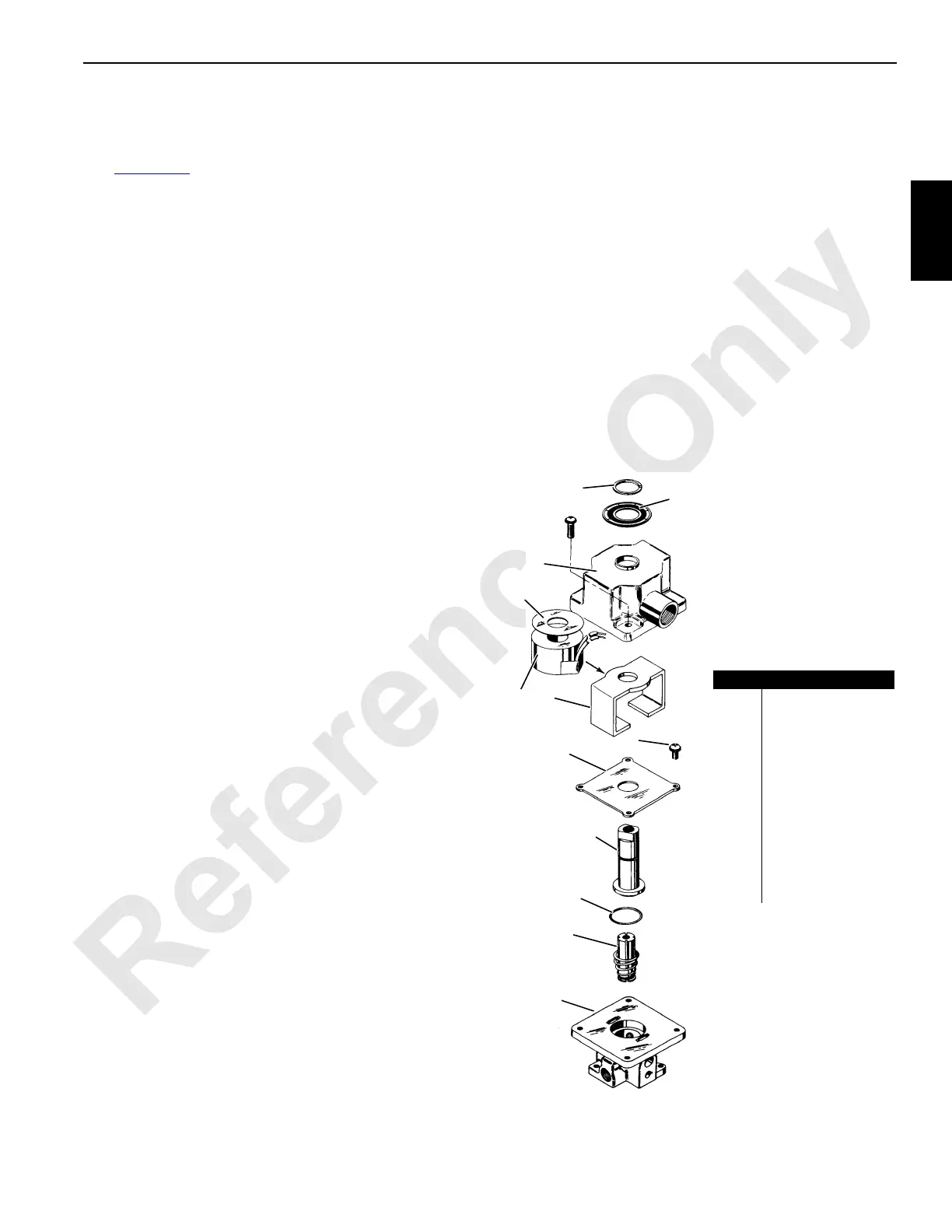

See Figure 2-38 for the following procedures.

If the valve fails to operate at all, check the coil (5) for

shorted or open turns. Also check the supply current. See

the following troubleshooting topics if the coil is not

damaged.

Troubleshooting—External Leakage

If leakage occurs around the sleeve (9), the metering pins, or

the manual override stem, the O-rings (10) should be

removed and inspected for imperfections.

Troubleshooting—Sticking or Internal Leakage

If the valve leaks internally or the plunger (11) sticks in the

energized position, examine the soft inserts in the plunger

ends or inside the sleeve (9) for excessive dirt or wear. If the

inserts show considerable wear, the plunger should be

replaced.

Troubleshooting—Noise

If the valve develops a loud buzzing noise, check the voltage

and pressure to determine if they correspond to the

nameplate (2) rating. Examine the inside of the sleeve (9)

and the upper portion of the plunger (11). Remove all foreign

matter embedded in these parts. Do not damage the sleeve

seat.

NOTE: Do not expose the plunger or O-rings (10) to any

type of commercial cleaning fluid. Clean the

plunger and O-rings with a mild soap-and-water

solution.

Disassembly

1. Shut off pressure and electricity to the valve. The valve

does not need to be removed from the line.

2. Remove the screws from the housing (3).

3. Remove the housing from the valve assembly.

4. Remove the yoke (6) and coil (5) with an upward

twisting motion.

5. Remove the screws (7) that hold the housing plate (8) to

the body (12).

6. Remove the housing plate, sleeve (9), and plunger (11).

Reassembly

1. Place the housing plate (8) over the sleeve (9).

2. Apply a light oil to the O-ring (10) flange seal. Always

assemble the O-ring to the sleeve before inserting in

valve bodies.

3. Make sure the plunger (11) and the return spring are in

place and then push the sleeve, along with the housing

plate, down in place on the body (12) with a slight

twisting motion.

4. Hold the housing plate down and replace the screws (7).

Tighten the screws to 2 ± 0,3 Nm (18 ± 3 in-lb). Place

these screws so they give the desired orientation of the

housing later in reassembly.

5. Apply pressure to the port that leads to the body

chamber and check for leakage around the flange seal.

If the valve has a sleeve port, cap the port at the top of

the sleeve to perform this test.

6. Check for leakage by applying a soap-and-water

solution to the joint and watch it for air bubbles.

7. Once the housing plate is secure, push the yoke (6) and

coil (5) over the sleeve with a slight twisting motion.

8. Install the housing with two screws. Tighten the screws

to 2 ± 0,3 Nm (18 ± 3 in-lb).

9. Repeat the internal leakage check.

FIGURE 2-38

S127

Item Description

1 Nameplate Retainer

2 Nameplate

3 Housing

4 Coil Washer

5Coil

6Yoke

7 Screw (qty 2)

8 Housing Plate

9Sleeve

10 O-ring

11 Plunger

12 Body

1

2

3

4

5

6

7

8

9

10

11

12

Loading...

Loading...