HYDRAULIC AND AIR SYSTEMS 2250 SERVICE/MAINTENANCE MANUAL

2-8

Published 07-19-16, Control # 249-01

4. Tighten the jam nut. When the fitting is properly installed,

the O-ring will completely fill the seal cavity and the

washer will be tight against the spot face (View B).

Table 2-4. Straight Thread Leakage

ORS

®

Connection

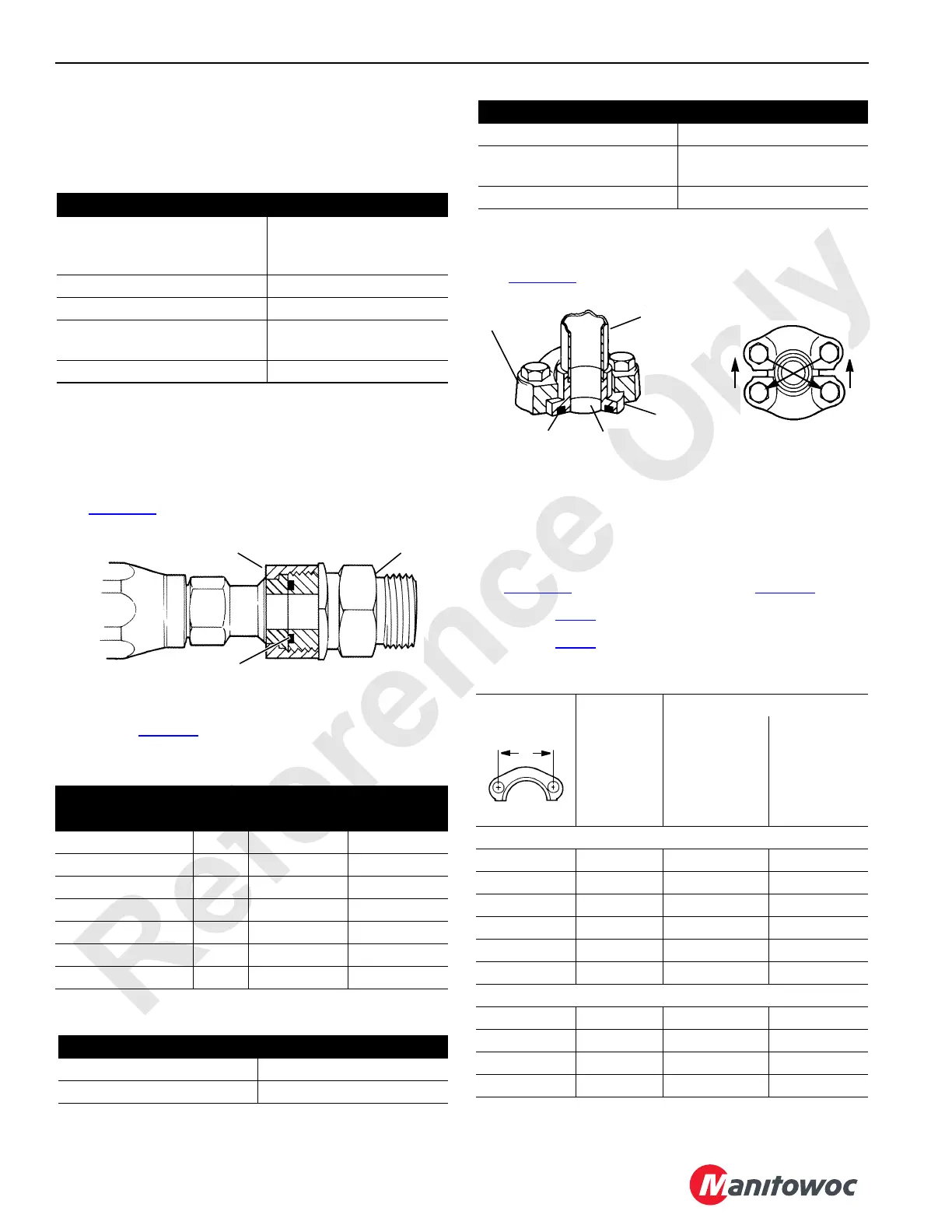

NOTE: ORS

®

is the registered trademark for a face-type

seal manufactured by Aeroquip Corporation.

1. Lubricate and install the O-ring in the adapter groove

(Figure 2-7

).

2. Lubricate the threads. Tighten the nut to the torque value

given in Table 2-5

.

Table 2-5. ORS

®

Assembly Torque

Table 2-6. ORS

®

Leakage

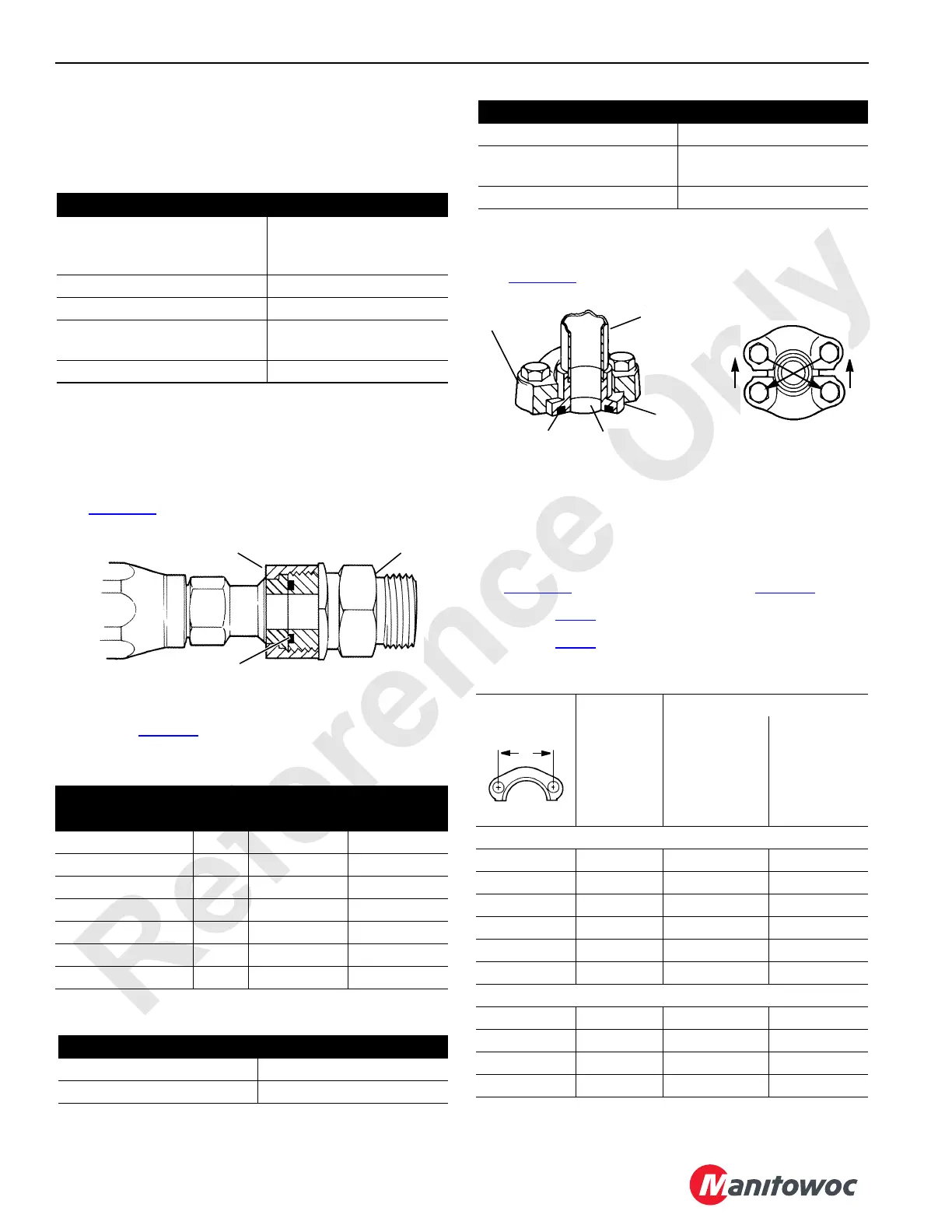

Split Flange Connection

1. Lubricate and install the O-ring in the shoulder groove

(Figure 2-8

).

2. Align the shoulder with the port and assemble the

flanges over the shoulder.

NOTE: The bolts used must be grade 5 or better. A grade 5

bolt has three dashes in its head.

3. Snug the bolts in a diagonal manner as shown in

Figure 2-8

to 1/3 of the torque given in Table 2-7.

4. Repeat step 3

to 2/3 of the final torque.

5. Repeat step 3

to the final torque.

Table 2-7. Split Flange Assembly Torque

Cause Cure

Jam nut and washer not

backed up at assembly,

causing O-ring to be pinched

Replace O-ring and tighten

fitting properly

O-ring cut Replace

O-ring wrong size Replace with proper size

Sealing surfaces are scratched

or gouged

Repair if possible or

replace damaged parts

Sealing surfaces dirty Clean and lubricate

Nut Size

(inch across flats)

Fitting

Size

Torque

Nm in-lb

5/8 -04 14 to 16 120 to 145

13/16 -06 23 to 28 203 to 245

15/16 -08 43 to 53 380 to 470

1-1/8 -10 62 to 77 550 to 680

1-3/8 -12 86 to 107 763 to 945

1-5/8 -16 125 to 142 1110 to 1260

1-7/8 -20 170 to 190 1500 to 1680

Cause Cure

Nut loose Tighten to proper torque

O-ring cut Replace

FIGURE 2-7

S105

Nut

Adapter

O-ring

O-ring wrong size Replace with proper size

Sealing surfaces gouged or

scratched

Repair/replace damaged

parts

Sealing surfaces dirty Clean and lubricate

Dimension A

inch

Flange

Size

Torque

Nm in-lb

Standard Pressure Series

1-1/2 -08 20 to 25 175 to 225

1-7/8 -12 25 to 40 225 to 350

2-1/16 -16 37 to 48 325 to 425

2-5/16 -20 48 to 62 425 to 550

2-3/4 -24 62 to 79 550 to 700

3-1/16 -32 73 to 90 650 to 800

High Pressure Series

1-9/16 -08 20 to 25 175 to 225

2 -12 34 to 45 300 to 400

2-1/4 -16 57 to 68 500 to 600

2-5/8 -20 85 to 102 750 to 900

Cause Cure

FIGURE 2-8

S104

1

2

3

4

S101

Flange

Tube

Shoulder

O-ring Port

Loading...

Loading...